Microstructure and Grades of Carbide

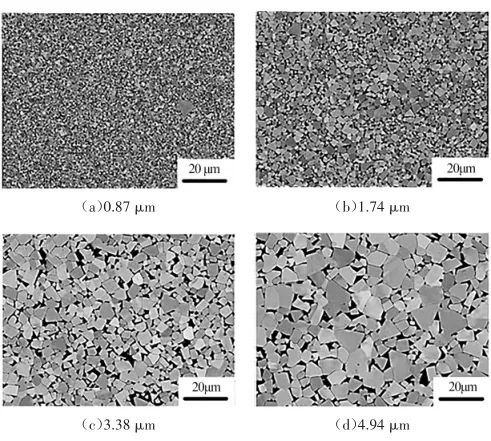

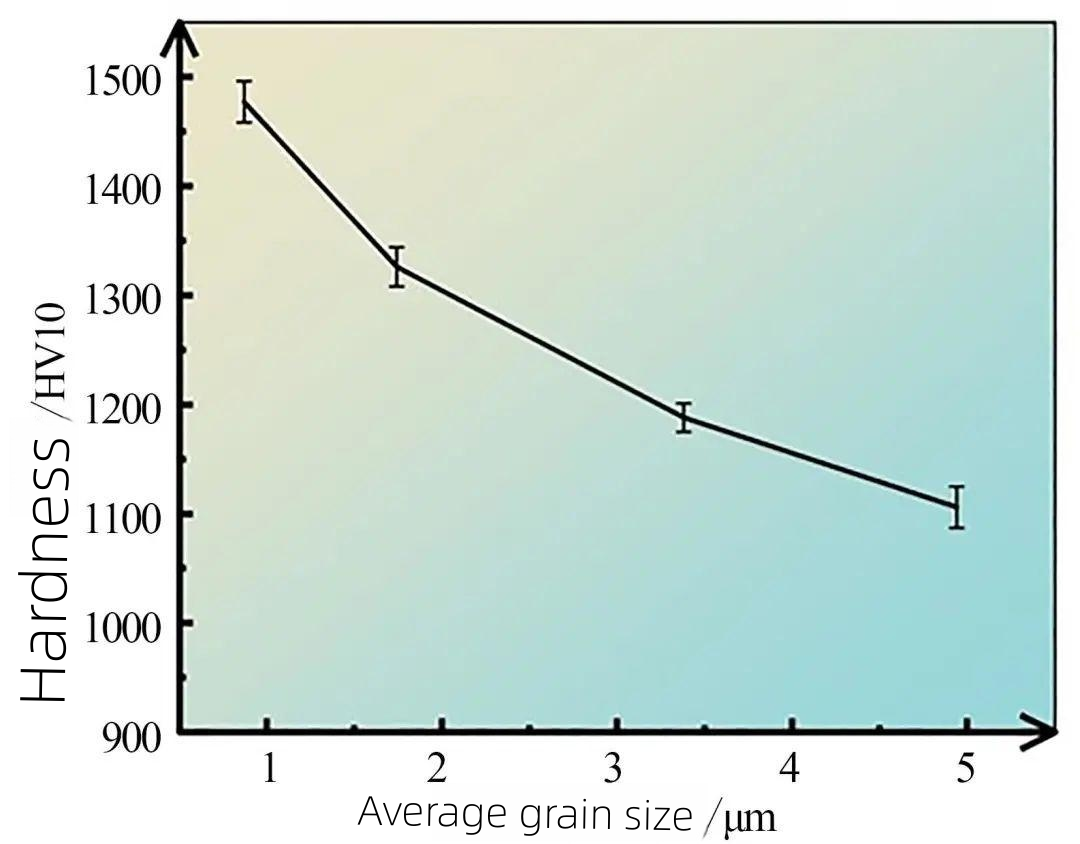

The properties of cemented carbideintered bodies are determined by their microstructure. Figure 1 shows SEM images of cemented carbide with different grain sizes, and Figure 2 shows the relationship curve between hardness and grain size. The larger the grain size of the hard phase in cemented carbide, the lower the hardness and the higher the toughness, and vice versa. Currently, the widely used grain sizes of cemented carbide in mold preparation include fine grain, medium grain, coarse grain, and ultra-coarse grain. The appropriate grain size is selected based on different requirements for wear resistance and impact toughness. Additionally, when the grain size of the hard phase in cemented carbide reaches the nanometer level, it can achieve a “dual high” state of high hardness and high toughness, resulting in ultra-high-strength cemented carbide.

In addition to grain size, the different organizational structures of cemented carbide also affect its properties. The commonly seen gradient-structured cemented carbide and twin-structured cemented carbide have special properties and are suitable for specific applications. For example, cemented carbide with a fine grain size on the surface and a coarser grain size internally is suitable for making deep-drawing dies and punch dies.

Plastic Forming Mold Made by Carbide

Table 1 shows the performance parameters of several commonly used grades of cemented carbide and traditional mold steels. The parameters in Table 1 are specific to a certain process. In actual use, the performance needs to be determined based on the preparation process and subsequent treatments to ensure it meets the production requirements. However, from Table 1, it can be observed that cemented carbide has higher hardness than mold steels but poorer impact toughness, and this trend becomes more significant with decreasing Co content.

Apart from the performance differences, compared to mold steels, the production of cemented carbide poses greater difficulties and has higher unit cost for components. The average manufacturing cost of carbide molds is approximately 2 to 4 times that of molds made from ordinary steel. Therefore, using them in small batch production, with simple shapes and light loads, would result in excessively high production costs for formed parts. What’s important is the lifespan of carbide molds can reach 20 to 40 times that of molds made from ordinary steel and 5 to 10 times that of traditional mold steels. The single-edge grinding life is 10 to 30 times longer than that of molds made from ordinary steel. This effectively reduces the number of mold repairs, improves production efficiency, and thus, using cemented carbide molds for parts with large production quantities and high precision requirements can actually reduce the average processing cost per formed part.

In plastic forming molds, the punch and extrusion molds are commonly used for continuous large-scale production and require high hardness for the mold components. Therefore, the following will mainly introduce the application and performance advantages of cemented carbide in these two types of molds.

Carbide Stamping Dies

Stamping is a manufacturing process that utilizes pressure machines and molds to apply external forces to sheet metal, strip materials, pipes, profiles, and other blanks, causing them to separate or undergo plastic deformation in order to achieve the desired shape and dimensions of the parts. Stamping is widely used in various industries due to the high complexity, high repeatability accuracy, and high production efficiency of the parts it produces.

In stamping molds, tools such as progressive dies and high-speed punching dies are used for large-scale production. These molds endure long-term high-frequency impact forces, shear forces, and friction forces. Therefore, in order to ensure the dimensional and shape accuracy of the produced parts as well as the lifespan of the molds, materials with high hardness, high strength, good fatigue resistance, and anti-sticking properties are required for the preparation of such molds. Cemented carbide is one of the suitable materials for this purpose.

Carbide Molds for Separation Process

Using materials with high hardness and wear resistance, such as cemented carbide, to manufacture blanking dies can extend the lifespan of the molds. According to statistics, the lifespan of cemented carbide blanking dies is 20 to 50 times longer than that of die steel blanking dies, and their single-edge grinding lifespan can reach millions of strokes.

However, cemented carbide has poorer impact toughness. To prevent premature failure of cemented carbide blanking dies, appropriate grades of cemented carbide are selected based on the requirements of impact toughness. Common grades include YG8, YG8X (X represents fine-grained), YG11, etc. In the case of thick plate blanking, as the plate thickness increases, the clearance between the punch and die also increases. During the blanking process, the plate material generates significant tearing, and the punch and die edges experience greater radial stress. The increased plate thickness also leads to increased impact force. To avoid cracking and premature failure of the molds, cemented carbide with higher cobalt content and coarser grain size, such as YG15, YG15C (C represents coarse-grained), YG18C, YG20, YG25, etc., should be selected.

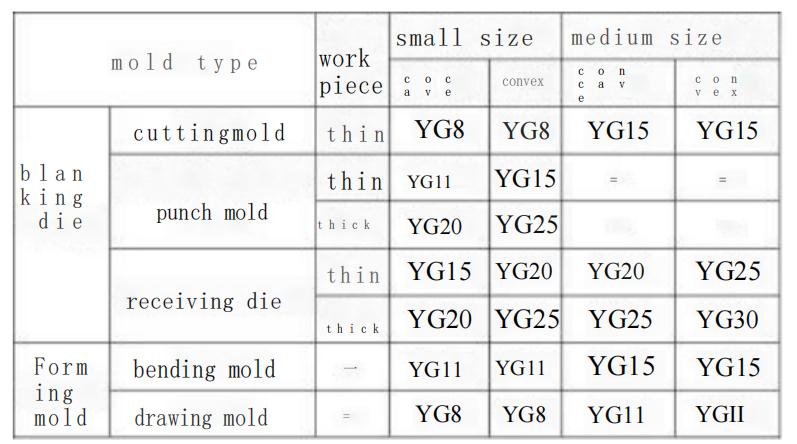

Recommended grades of cemented carbide for different working conditions in blanking dies are shown in Table 2. For example, YG15 and YG11 are used to manufacture the punch and die components, respectively, for simple contour punching dies or box-shaped blanking dies. For complex-shaped blanking dies with the same material and thickness, cemented carbide with higher cobalt content, such as YG20 and YG15, should be used.

Carbide Processing Dies

Cemented carbide widely used in the preparation of forming molds is tungsten-cobalt cemented carbide. Common national standard grades include YG8, YG11, YG15, YG20, YG25, YG30, etc. As indicated by the recommended grades in Table 2, in drawing dies, especially deep-drawn parts, where there is significant friction between the mold components and the blank, grades with low cobalt content are chosen to achieve high hardness and wear resistance, such as YG8 or YG11. In bending dies, where the molds are subjected to significant impact forces, it is recommended to select grades with higher cobalt content to obtain better impact toughness, such as YG11 or YG15.

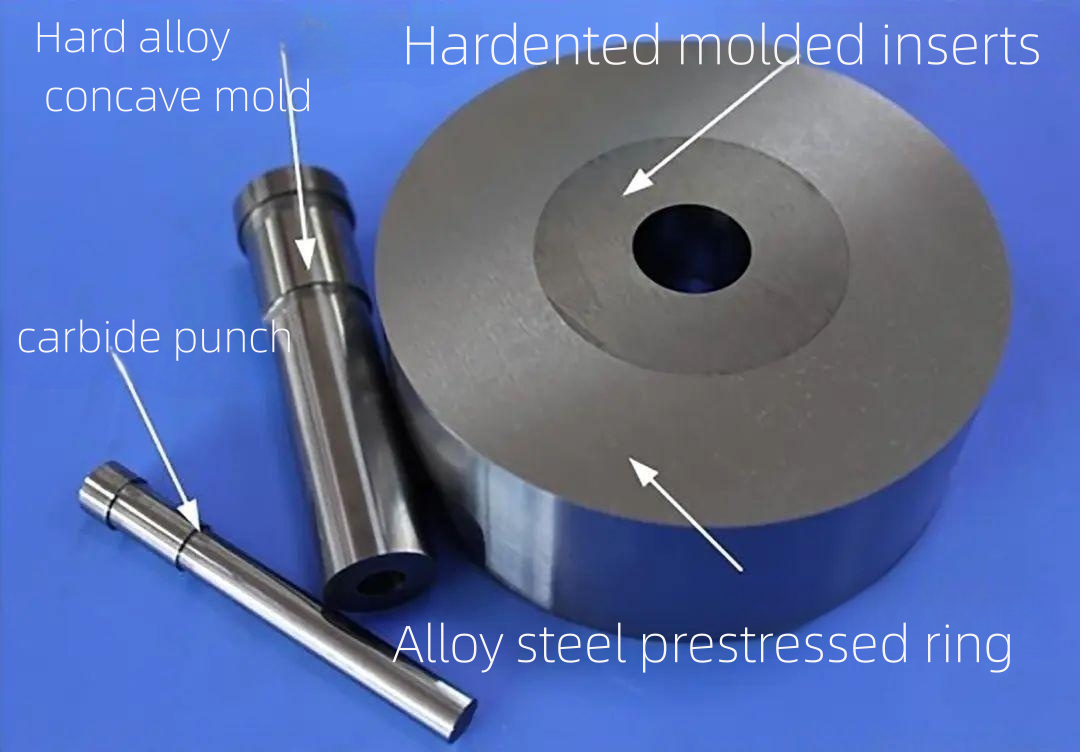

After selecting the appropriate grade, in the design of the molds, if the mold size is too large, it can lead to difficulties and high costs in the fabrication of the entire cemented carbide mold. Therefore, it is common to use cemented carbide to prepare mold components or inserts, as shown in Figure 1. Figures 3(a) and 3(c) depict molds with smaller radial dimensions, allowing for the use of cemented carbide to fabricate the entire mold. On the other hand, in Figures 3(b) and 3(d), where the molds have larger overall dimensions, it is advisable to use cemented carbide to manufacture the working components of the mold or the parts with higher performance requirements. This approach can reduce mold manufacturing costs and processing difficulties.

Carbides Extrusion Dies

Cold extrusion processing causes severe deformation of the billet at room temperature, resulting in work hardening, increased hardness, and strength of the final part. It also provides good surface quality and allows for precise machining of parts with complex cross-sections, internal teeth, blind holes, and other features that are difficult to process by other means. Therefore, cold extrusion finds wide application and is commonly used to produce various fasteners, such as bolts, and automotive components.

The material requirements for the punch in cold extrusion include good impact toughness, bending strength, compressive strength, fatigue resistance, and thermal stability. Therefore, punches for cold extrusion are typically made from tungsten-cobalt cemented carbide with high cobalt content, such as YG15, YG20, YG20C, YG25.

Compared to the punch, the die in cold extrusion is subjected to lower impact forces but has to withstand severe friction and significant radial tensile stresses. Therefore, it is advisable to choose a harder cemented carbide, such as tungsten-cobalt cemented carbide with low cobalt content and fine grain size, such as YG8, YG10, YG15X, or to use tungsten-titanium-cobalt (YT) cemented carbide with hardness higher than tungsten-cobalt cemented carbide, such as YT15. However, these two types of cemented carbide have poor toughness and high sensitivity to stress, making them unsuitable for forming complex parts.

Figure 4 shows the punch, punch and die inserts, and preload rings of cemented carbide extrusion molds.

Carbide?Hot Extrusion Dies

The service life of cemented carbide using GW1 steel as a binder can reach over 1,000 pieces, while using the American D43 binder can reach over 4,000 pieces. By using RW40 steel-bonded cemented carbide and subjecting it to heat treatment followed by boronizing treatment, the service life can be improved by 10 to 15 times compared to traditional die steel. The use of DT series steel-bonded cemented carbide, which is forged and heat-treated, as a replacement for cast steel in die materials for extrusion steel balls, can increase the die’s service life by nearly 20 times.

Additionally, due to the small thermal expansion coefficient of cemented carbide, it is beneficial for improving the dimensional and shape accuracy of produced parts. However, tungsten-cobalt cemented carbide is sensitive to stress concentration and is not suitable for extruding complex-shaped products. It is commonly used in the production of various standard parts, simple-shaped profiles, and other products. For example, in the extrusion dies for aluminum tube profiles, tungsten-cobalt cemented carbideuch as YG8 can be used, with a working temperature of around 500°C, and it can process 11,000 to 23,000 kg of aluminum tubes within its service life. YG15 and YG20 are commonly used in cemented carbide inserts for extruding parallel-flow aluminum flat tubes.

結(jié)論

The high hardness, high fatigue strength, and high wear resistance of cemented carbide ensure the service life of the mold. Its high hot hardness, low linear expansion coefficient, and good oxidation resistance guarantee the dimensional accuracy and stability of cemented carbide molds under conditions of cold-hot alternation and high temperature. Cemented carbide does not require heat treatment, so there are no issues with dimensional or hardness changes over time. Therefore, cemented carbide is suitable for the preparation of plastic forming molds such as punching dies and extrusion dies. For deep drawing dies, extrusion concave dies, and other applications with high wear resistance requirements, low-cobalt tungsten-cobalt cemented carbide is generally used. When it comes to punching dies, bending dies, extrusion convex dies, and other applications with high toughness requirements, high-cobalt cemented carbide or steel-bonded cemented carbide is generally used. Currently, the most commercially used cemented carbide in molds in China is tungsten-cobalt cemented carbide, followed by steel-bonded cemented carbide and tungsten-titanium-cobalt cemented carbide.

The production volume of cemented carbide in our company has been continuously increasing. However, we have also identified a series of issues regarding the current application of cemented carbide in molds. For example, cemented carbide molds are costly, making them suitable only for high-volume and high-precision high-end molds. Due to limitations in the manufacturing process of cemented carbide, the size of cemented carbide blanks is relatively small. Currently, the radial dimension is generally less than 100 mm, which also limits the size of cemented carbide molds. Cemented carbide is difficult to process, and even with advanced machining methods, some challenges remain.