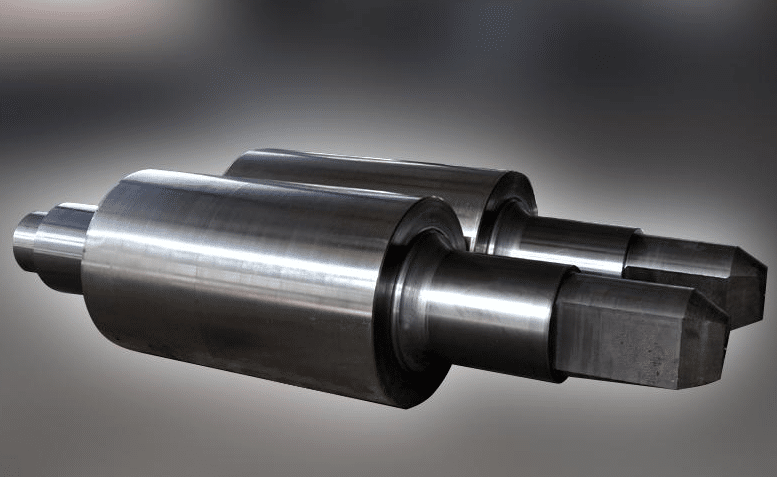

At present, in order to improve the operation rate of the rolling mill and reduce the consumption of the rolling spokes, especially for the finishing spokes whose pass is easy to wear, the rolling spokes with high surface hardness are mostly used, such as high speed steel rolling root, carbide rolling root, cemented carbide rolling root, etc, The high surface hardness of rolling spokes brings many difficulties to the processing, which affects the processing quality and efficiency of rolling spokes.

In view of this situation, it is necessary to carry out technical research on the processing technology of high hardness rolling process, so as to eliminate the problems such as vibration, turning difficulty and dimensional accuracy deviation in processing due to the high hardness of rolling root.

Analysis of processing technology

Aiming at the phenomenon that the rolling root is easy to vibrate in the processing, the stability of rolling in rotation is improved by improving the clamping mode of turning tool and the positioning mode of rolling spoke;

Through the analysis of the cutting performance of the hard spoke, the suitable tool material is selected to realize the high-quality processing of the spoke;

Optimize the processing flow of Web rolling, meet the high precision and improve the processing efficiency;

Reduce the cost of rolling, reduce the consumption of cutting tools and other materials.

Key technology points

The outer circle is turned with small back angle, wide blade, low speed and large feed rate;

The large pass is turned by the method of slicing and single side forming;

The rotation speed and feed rate of lathe spindle are optimized to eliminate the vibration during machining;

Rough turning first and fine turning with small allowance to reduce grinding time of fine turning tool;

The application of reverse feed turning can reduce the cutting parameters.

Optimization of processing technology

Control of processing quantity

The machining allowance has a great influence on the machining quality and production efficiency. Excessive machining allowance not only increases the labor of machining, reduces productivity, but also increases the consumption of materials, tools and electricity, and increases the processing cost. If the machining allowance is too small, it can not be used

Eliminating all kinds of defects and errors in the previous process can not compensate the clamping error in this process, resulting in waste products. Therefore, on the premise of ensuring the quality, strengthen the control of processing quantity to make the allowance as small as possible. Generally, the more finishing, the smaller the process allowance.

When the feed rate of the workpiece is selected, the surface finish of the rolling and digging is considered, and the cutting depth is determined according to the machining allowance. After the cutting depth is selected, the maximum feed rate is selected according to the strength of the tool feed mechanism, tool life and workpiece hardness to improve the machining efficiency. The feed rate of finish turning is mainly selected according to the surface finish requirements. Because the feed rate will affect the surface finish of the workpiece to a certain extent, reasonable selection of the back feed rate, feed rate and cutting speed plays an important role in ensuring the processing quality and improving the production efficiency. In order to improve the processing efficiency of rolling, the feed rate should be selected first, the cutting depth should be selected second, and the higher spindle speed should be selected on the premise of satisfying the tool life.

Control of cutting parameters

Improve and optimize the processing parameters. The runout of the spoke is corrected after clamping on the lathe. At the end close to the lathe chuck, the runout w0.03 mm of the upper bearing position and w0.06 mm of the bearing position at the tailstock end are qualified.

In the new rolling process of rough turning outer circle, the turning amount is usually the smaller diameter one which can be rounded, and the repairing amount of the old one is generally 4.5-6 mm. After rough turning, there is a finish turning allowance (diameter) of 0.5-1 mm for the outer circle. On the one hand, after rough turning, there may be taper problems at the left and right ends of the outer circle due to tool wear, accuracy of the bed itself and other problems. The finish turning allowance can be reserved after the hole is machined, and the outer circle can be turned to the required size. On the other hand, due to the fine turning allowance, the machining efficiency can be appropriately improved when the rough pass is turned at the back.

Control of cutting mode

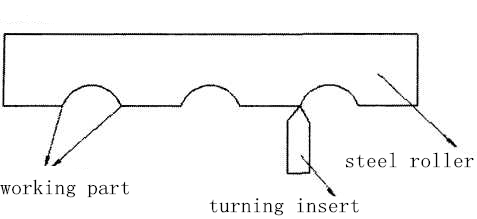

Chamfering the old rolling spoke before turning the outer circle, as shown in the figure. The advantage of chamfering before turning the outer circle is that when turning the edge of the hole, the peeling caused by stress concentration is eliminated

If there is a large amount of processing for the rough turning of the outer circle and it is necessary to turn the outer circle for many times, according to the rolling processing situation, lathe accuracy and measurement results, the method of alternating processing from left to right and then from right to left is adopted to turn the outer circle, so as to reduce the taper error of the outer circle

The specific parameters of rough turning are as follows:

Tool material: YD05 (can be the same tool with chamfering) spindle speed: 11 rpm

Maximum feed: 1.75 mm (unilateral) maximum automatic feed: 0.25 mm / revolution

When roughing the pass, use the single hole forming turning tool to turn the first groove of the spoke, and check the turning condition with the template at any time. When turning, the spindle speed is 2-2.8 rpm, the feed is 0.15-0.25 mm / rpm, and the feed mode is manual feed. Because the rolling material is hard, and sometimes there is uneven hardness on the excavation surface due to material segregation, the automatic feed is not easy to control, and in serious cases, the machined pass will have roundness error, which has a great impact on steel rolling. With manual feed, the feed speed can be accelerated or slowed down according to the hardness of rolling, which is easy to control.

Rough turning cutting parameters: tool material: ys8 spindle speed: 2-2.8 rpm

Feed: 0,15-0.25 mm / Revolution (preferably manual feed)

Finish turning the outer circle, use the cylindrical turning tool to finish turning the surface. Before turning, measure the whole surface to determine which side has larger taper, then feed from that side. Check the machining accuracy after turning. The requirement of outer taper is w0.25 mm. The cutting parameters are the same as that of rough turning, but the cutting quantity is small and the precision is high.

Finishing pass is processed by forming cutter because the shape allowance of the whole pass is 0.3-0.4mm when rough turning. Because the material is hard, the method of slow feed is adopted, and the speed needs to be adjusted to the slowest speed. In the process of processing at any time with the finish turning sample for inspection.

Cutting parameters: tool material: YG6X (or better tool) spindle speed: 1 rpm.

Pass machining is divided into rough turning and finish turning. The forming pass cutter is redesigned and divided into rough turning cutter and finish turning cutter. Rough turning tool without arc can improve the processing efficiency, while finish turning tool with arc according to the pass can reduce the labor intensity of turning tool and improve the pass processing quality.

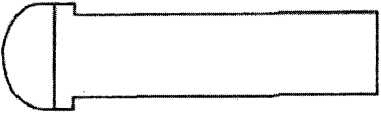

Sketch of rough turning tool (without R)

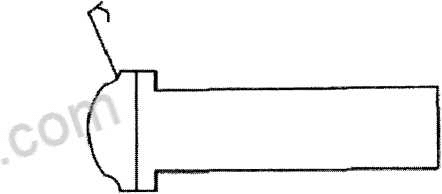

Design of finish turning tool (with R)

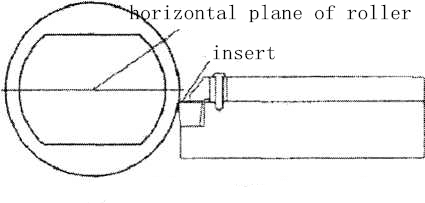

CNC lathe has high machining accuracy, but there are some shortcomings in the machining process, such as fast wear of CNC blade and short service cycle of arbor. Through the research, it is found that the horizontal cutting surface of NC blade is higher than that of the weak rolling surface, and the original design of NC Arbor and the size of assembly with blade are unreasonable. Therefore, the thickness and width of the NC cutter bar and the length of the straight section of the cutter bar head are optimized and adjusted. When the horizontal cutting surface of NC blade is installed at a lower position than the rolling water plane, and the fit tolerance is controlled at 0-0.5 mm, the rolling turning effect is the best

After the improvement, the service life of NC Arbor and blade has been greatly improved

Effect after implementation

Through the optimization of root rolling process, the efficiency and quality of spoke rolling process have been improved significantly. Some problems that often restrict the efficiency of root rolling process have also been solved

1. According to the hardness of the rolling root, the processing can be made easier, the efficiency can be increased by more than 20%, and the rolling capacity of small single groove can be increased by 10%

2. By optimizing the tool material, the machining efficiency can be increased by 25%, and the tool consumption can be reduced.

3. Turning the outer circle with small back angle and wide blade tool at low speed and large feed rate makes the outer circle which used to be finished in 3 hours can be finished in 1.5 hours now. The machining efficiency is more than doubled, the tool wear is small, and the rolling radius cylindricity is guaranteed.

4. The method of layer cutting and single side forming is used to turn the large pass, which overcomes the defects of low strength and large vibration of the machine tool. The method of rough turning first and fine turning with small allowance is adopted, which greatly reduces the time of grinding the fine turning tool and improves the quality of pass processing. The application of the above method can reduce the tool loss by 30%.

5. The cutting depth, feed rate and cutting speed are all increased by 20%.