Table 1 Mechanical and Thermal Properties of Common Hard Coatings Strength of materials

| Nguyên v?t li?u | Melting point or decomposition temperature(℃) | ?? c?ng

HV MPa |

Yang’s

modulus kN/mm2 |

Coefficient of thermal expansion

10-6k-1 |

Thermal conductivity

W/(m.K) |

|

| Al2O3 | 2047 | 21000 | 400 | 6.5 | ~25 | |

| Diamond | 3800 | 80000 | 1050 | 1 | 1100 | |

| c-BN | 2730 | 50000 | 440 | |||

| SiC | 2760 | 26000 | 480 | 5.3 | 84 | |

| Si3N4 | 1900 | 17000 | 310 | 2.5 | 17 | |

| TiB2 | 3225 | 30000 | 560 | 7.8 | 30 | |

| TiC | 3067 | 28000 | 460 | 8.3 | 34 | |

| TiN | 2950 | 21000 | 590 | 9.3 | 30 | |

| Nhà v? sinh | 2776 | 23000 | 720 | 4.0 | 35 |

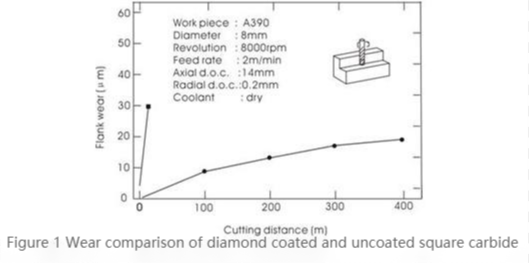

diamond carbide tools are generally classified into natural diamond carbide tools, polycrystalline diamond (PCD) tools, and diamond film-coated tools. Natural diamonds are rarely used in industry due to their scarcity and high cost. PCD tools have complex manufacturing processes, high costs, and limited variety, which restrict their widespread industrial application. On the other hand, the Plasma Chemical Vapor Deposition (PCVD) method allows for the deposition of diamond films on the surfaces of complex-shaped tools, improving efficiency and reducing production costs. Figure 1 shows a wear comparison between square carbide?vertical milling cutters with and without diamond coatings when machining silicon aluminum alloy. The CVD diamond film significantly extends the lifespan of carbide?tools, making diamond-coated tools a high-performance tool with promising development prospects.

2Improvement of preparation process

2.1 surface pretreatment

Due to variations in tool manufacturers, tool materials, and distribution channels, the surface condition of cutting tools can vary significantly. However, diamond coatings have strict requirements for the substrate surface condition. In order to obtain diamond-coated tools with stable quality, appropriate pretreatment of the substrate surface is necessary.

(1)Surface purification and coarsening

During the manufacturing process of carbide?tools, it is inevitable that some contaminants, adsorbates, and oxides will remain on the tool surface. These substances can hinder direct contact between the diamond film and the substrate, as well as affect the quality of subsequent processes. For example, surface residues of oil can affect the etching effect of acid on Co. Therefore, surface purification is necessary during pretreatment.

Common methods of purification include chemical cleaning and liquid ultrasonic cleaning. When purifying the tool surface, suitable purification agents should be chosen based on the tool manufacturing process of the tool manufacturer. Surface roughening can alter the microstructure of the substrate surface, remove WC particles with low surface adhesion, increase the specific surface area of the substrate, increase the surface energy of the substrate, improve the nucleation density of diamond on heterogeneous substrates, and enhance the adhesion between the film and the substrate. Common methods include mechanical grinding and liquid ultrasonic treatment.

(2)Surface seeding

Diamond powder suspended in a solution is used for ultrasonic treatment of carbide. For flat-surfaced tools, diamond powder can also be used as an abrasive for grinding. This not only removes surface impurities and facilitates the detachment of poorly adhered WC particles, but also increases surface roughness. Moreover, the residue of fragmented diamond powder within surface defects of carbide?provides nucleation cores for CVD diamond deposition, thereby enhancing nucleation density.

(3)Optimization of surface force points

Due to the significant thermal stress between diamond and the substrate, this thermal stress is concentrated more at the cutting edge of the tool. As a result, the adhesion between the diamond film and the substrate is particularly weak at the cutting edge. This can be addressed by optimizing the geometric shape of the stress point, such as increasing the ratio of r/h (where r represents the curvature radius of the cutting edge and h is the thickness of the diamond film). This helps reduce the lateral force between the diamond film and the substrate, disperses the load exerted on the diamond film during tool use, and extends the wear resistance of the diamond film.

2.2 Reducing the adverse effects of Co on diamond deposition

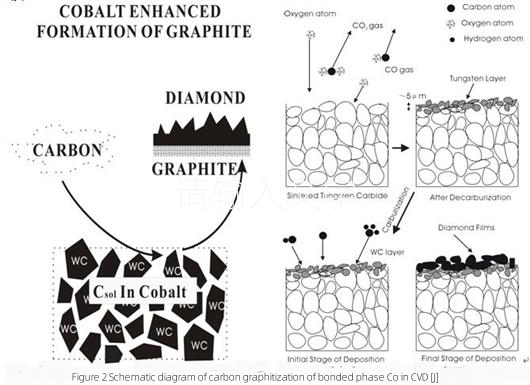

Due to the catalytic effect of Co on graphite formation at CVD deposition temperatures, it is necessary to avoid direct contact between Co and the diamond film or eliminate the reactivity of Co.

(1)acid etching

Due to the electrode potential of Co being -0.28V, acids can be used to etch the surface layer of Co on the substrate. Commonly used acids include HCl, HNO3, H2SO4+H2O2, etc.

(2)plasma etch

This method involves treating carbides with hydrogen plasma or oxygen-containing hydrogen plasma to remove surface Co in the shallow layer by utilizing the reaction between plasma and Co to form volatile compounds. Simultaneously, WC is reduced to metallic W by the hydrogen plasma, and the metallic W combines with carbon in the subsequent CVD deposition of diamond films, forming small WC particles with sizes ranging from 10 to 100 nm. This refinement of the surface increases the contact area between the diamond film and the substrate, further enhancing the adhesion strength of the diamond film. Figure 3 illustrates the schematic of decarbonization and reduction.

(3) Passivated cobalt

Using chemical substances to react with cobalt metal, stable compounds are formed to deactivate the cobalt in the surface layer. Examples include chemical passivation and plasma passivation.

(4)Chemical reaction displacement method

The carbide?can be immersed in a chemical reagent, and through a displacement reaction, the surface cobalt metal can be replaced by another substance, thereby achieving the removal of cobalt from the surface layer. This method also takes into account the mechanical strength of the alloy. For example, copper (with an electrode potential of 0.343V) can be used to replace cobalt.

(5)Selection of substrate materials

Another approach is to directly use WC as the substrate without the adverse factors of the binder phase Co by employing high-temperature sintering. This allows the tool to withstand higher temperatures during diamond film deposition and accelerates the deposition rate. Alternatively, diamond particles can be added to the raw materials of the tool before hot pressing and sintering, and through appropriate processing techniques, a gradient of increasing diamond particle concentration can be formed from the body to the surface of the tool. In this way, the diamond in the tool serves as an excellent nucleation core for CVD diamond, thereby enhancing nucleation density.

2.3 Apply intermediate transition layer

The residual stresses within the diamond coating have a significant impact on adhesion. These residual stresses typically consist of two components: thermal stress σth and intrinsic stress σi. The thermal stress is caused by the difference in thermal expansion coefficients between the coating and the substrate. According to empirical formulas:

σth=Ef(αf-αs)(Ts-Tr)/(1-ψf)

Ef, ψf, and αf represent the elastic modulus, Poisson’s ratio, and thermal expansion coefficient of the diamond coating, respectively. They are taken as 1228 GPa, 0.07, and 1.0 × 10-6 K-1, respectively. αs represents the thermal expansion coefficient of the WC-6%Co cemented carbide substrate, which is taken as 5.4 × 10-6 K-1. Ts is the substrate surface temperature during deposition, taken as 1023 K, and Tr is room temperature, taken as 298 K. Based on these values, the estimated thermal stress in the coating is -4.21 GPa.?It ?prevents direct reactions between the film and the substrate during deposition, such as excessive carbon diffusion into the substrate and diffusion of Co from the substrate’s depths to the surface, which could affect diamond growth.

When selecting an intermediate transition layer material, the following factors should be considered:

- Moderate thermal expansion coefficient to accommodate the thermal stress between the diamond film and the substrate.

- Good adhesion to both the cemented carbide and diamond materials.

- Stable chemical properties and sufficient mechanical strength.

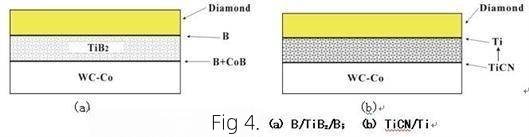

- Ability to react with Co to form stable compounds or prevent Co migration to the surface during high-temperature deposition. For example, when using a B/TiB2/B transition layer, the B on the substrate surface can react with Co to form stable CoB, thereby passivating Co. The surface layer of B can provide good adhesion to the diamond film, while the main body of the transition layer, TiB2, effectively inhibits Co migration. This structure is illustrated in Figure 4(a). A composite transition layer of TiCN/Ti can effectively prevent the formation of a third phase, Co3W3C, which may reduce the strength of the tool substrate due to decarburization treatment. Ti can form a strong connection with the diamond film, as shown in Figure 4(b).

2.4 Control of sedimentation process for carbide tool

The residual stress within the diamond coating also includes intrinsic stress (σi), which can be divided into growth stress and interface stress. The growth stress is mainly caused by compressive stress induced by impurities (graphitic carbon, amorphous carbon, hydrogen, etc.) in the coating and tensile stress generated by defects such as voids and dislocations. It is primarily influenced by the growth process. Therefore, controlling the deposition process can help improve the intrinsic stress.

(1)Temperature control

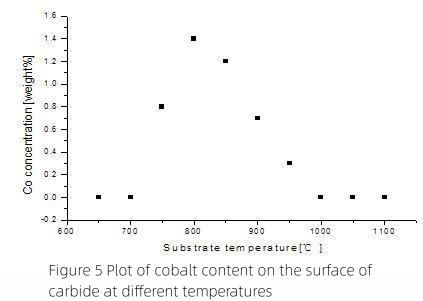

Temperature has a significant influence on the growth rate, morphology, and inherent quality of diamond films. Additionally, temperature has a notable impact on the migration of Co. At high temperatures, Co not only facilitates the conversion of carbon into graphite but also increases the migration rate of Co towards the surface. This leads to significant erosion of Co by plasma, resulting in a depletion of Co in the carbide?substrate phase and affecting the strength of the tool itself. Conversely, excessively low deposition temperatures can increase the non-diamond components in the film. Figure 5 illustrates the variation of cobalt content on the surface of the carbide?substrate with different temperatures.

Therefore, the suitable temperature range for depositing CVD diamond films on carbide?substrates is narrower compared to other materials such as Si or Mo. The deposition temperature can be lowered by utilizing halogens for enhanced etching of non-diamond carbon. For example, Trava-Airoldi et al. achieved a deposition temperature as low as 580°C by adding CF4 to the reaction gas.

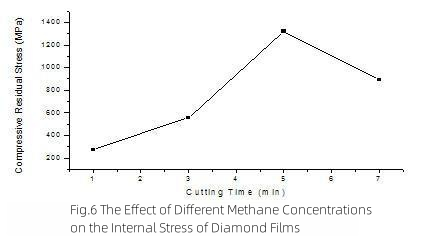

(2)Control of carbon containing gas source concentration

A high concentration of carbon-containing gas source can increase the growth rate of diamond films. However, it also leads to an increase in non-diamond components within the diamond film. Therefore, it is essential to control the concentration of the carbon-containing gas source. Figure 6 illustrates the influence of different methane concentrations on the internal stress of diamond films.

(3)Diamond doping

Doping diamond with a small volume of boron (B) can improve the chemical composition of the carbon transition layer between the diamond film and the substrate, enhancing the bonding strength between the film and the substrate. It also helps improve the stress distribution within the interface layer. Boron sources used for doping include B203 and B2H6.

2.5 Treatment after sedimentation

This method involves slow cooling of the coated tool once the diamond film has reached the desired thickness, aiming to reduce the thermal stress caused by thermal expansion differences.

The aforementioned methods have been introduced to enhance the adhesion between the diamond film and the carbide?substrate. In practical applications, multiple methods are often combined and implemented based on specific requirements and needs.

3 Existing problems and prospects

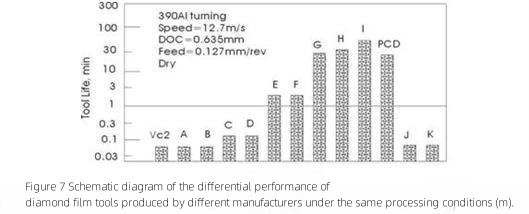

Currently, although some foreign companies have diamond-coated cutting tools available on the market, the constraints on adhesion have limited their application to only a few grades of carbide?tools. Moreover, the thickness of the diamond coating is generally less than 30 μm. As shown in Figure 7, there is significant variation in performance even among products from the same manufacturer. Additionally, for special geometric tools like end mills, it remains a challenge for researchers to control the heat flow and ensure uniform heating during mass production. Therefore, future research directions for the process of diamond-coated carbide?tools can be categorized as follows:

- Expanding the range of carbidetools that can be coated with diamond.

- Increasing the thickness of the diamond coating.

- Ensuring stability and consistency in quality during large-scale production.

Vc2 represents uncoated carbide?tools, PCD represents polycrystalline diamond carbide tools, and others represent CVD diamond-coated tools.

In summary, the production challenges of CVD diamond-coated carbide?tools lie in the less-than-ideal adhesion. However, recent research progress indicates that in-depth studies on improving adhesion processes have significant implications for producing high-quality, cost-effective diamond-coated tools that meet industrial application requirements.