Although burr is not big, it directly affects the quality of products. Therefore, with the attention of various industries to deburring, deburring methods are emerging in an endless stream. Commonly used trimming / deburring are as follows:

Deburring, chamfering these small processes are often in the work can not be underestimated, today we summarize some of the information shared in the past, hoping to bring help to everyone’s work.

manual works

Traditional; and the trimming knife gradually replaces these traditional methods, without technical treatment, cost saving and environmental protection.

Chemistry method

Based on the principle of electrochemical reaction, deburring of metal parts can be done automatically and selectively. It can be widely used in deburring of different metal parts of pump body, valve body, connecting rod, plunger needle valve couple, etc. in pneumatic, hydraulic, engineering machinery, nozzle oil pump, automobile, engine and other industries. It is suitable for internal burr that is difficult to remove, parts after heat treatment and finish machining.

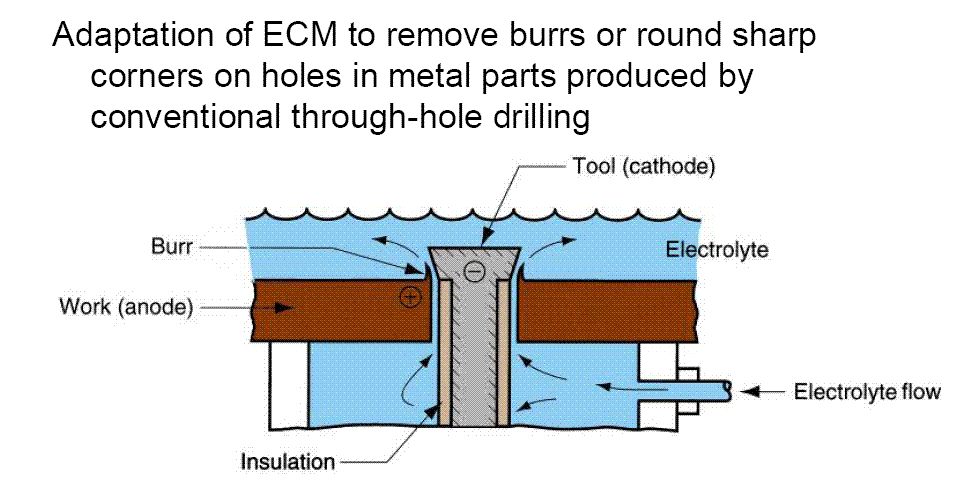

Electrolysis method

An electrochemical machining method for deburring metal parts by electrolysis. Fix the tool cathode (usually brass) near the burr part of the workpiece, with a certain gap (generally 0.3-1MM) between them. The conductive part of the tool cathode is aligned with the burr edge, and other surfaces are covered with insulating layer, so that the electrolysis is concentrated on the burr part. During machining, the cathode of the tool is connected with the negative pole of the DC power supply, and the workpiece is connected with the positive pole of the DC power supply. A low-pressure electrolyte (usually sodium nitrate or sodium chlorate aqueous solution) with a pressure of 0.1-0.3 MPa flows between the workpiece and the cathode. When the DC power supply is connected, the burr will generate anode dissolution and be removed, which will be taken away by the electrolyte. The electrolyte is corrosive to some extent. After deburring, the workpiece shall be cleaned and antirust treated. Electrolytic deburring is suitable for deburring cross holes or complicated parts in concealed parts. It has high production efficiency and takes only a few seconds to tens of seconds. This method is often used for deburring gears, splines, connecting rods, valve bodies and crankshaft oil way orifices, as well as rounding off sharp corners. The disadvantage is that the burr near the part is also affected by electrolysis, the surface will lose its original luster, and even affect the dimensional accuracy.

Ultrasonic method

When the ultrasonic energy generated by ultrasound acts on the liquid in which the vibration is in a sparse state, it will tear into very small holes (that is, the internal is a vacuum). These holes will generate up to hundreds of atmospheric pressure instantaneous pressure when they break, which is called cavitation phenomenon. Ultrasonic deburring is to use the instantaneous impact force of hundreds of atmospheric pressure produced by “cavitation phenomenon” to remove the burrs attached to the parts. Ultrasonic deburring is not applicable to all burrs, mainly for some micro burrs. Generally, if the burrs need to be observed by a microscope, we can try to remove them by ultrasonic method. For the visible burr, it mainly depends on the bonding strength. The burr with weak bonding strength can be treated by ultrasonic. Generally, if the burr can only be treated by the cutter, the ultrasonic method is not available at all. Advantages and disadvantages of ultrasonic deburring.

High pressure water jet method

As the name implies, it takes water as the medium, uses its instantaneous impact force to remove the burr and flash generated after processing, and at the same time, it can achieve the purpose of cleaning. After many tests, a suitable pressure of 30mpa-50mpa was found. If the pressure is insufficient, the deburring effect cannot be achieved. If the pressure is too high, the deburring can be removed, but there is a risk of damaging the workpiece. Generally, the hydraulic parts bear the liquid pressure within 20MPa when they are in use, and the burr remains that cannot be removed with 50MPa pressure. The probability of falling off under the working pressure of several MPa is very small, and it can also be considered that the burr root remains is a part of the workpiece. There are more and more manufacturers of high pressure water deburring equipment, which can be simply divided into two categories: workpiece moving type and nozzle moving type. The workpiece moving type has low cost and is suitable for deburring and cleaning of simple valve body. Its disadvantage is that the fitting degree of nozzle and valve body is not ideal, and the deburring effect of cross hole and inclined hole in valve body is not good; the nozzle moving type can effectively adjust the distance between nozzle and valve body where the burr is generated, effectively corresponding to the burr of cross hole, inclined hole and blind hole in valve body through CNC control, but the burr of the blind hole is caused by Because of the high cost of this equipment, only the heart of the car and the hydraulic control system of the construction machinery can enjoy this treat.

Thermal explosion method

Also known as electric thermal deburring, thermal deburring is recognized as the most suitable advanced technology for large-scale deburring of small workpieces in the world’s machinery manufacturing industry. Only two domestic enterprises can produce this equipment. It uses hydrogen and oxygen to mix in the closed chamber which is used to treat the workpiece, ignites and burns instantly, and has a violent thermochemical reaction with the workpiece surface burr in a very short time, so as to achieve the purpose of burr removal. Thermal deburring is a special processing technology, which has the characteristics of high efficiency, high universality, good accessibility, even and thorough deburring, smooth workpiece surface, and not limited by workpiece material, shape and burr position. It is especially suitable for deburring of workpieces with complex cavity, intersecting hole system, deep hole, blind hole, threaded hole and other difficult deburring which cannot be solved by other process methods. It can be used for deburring of non-metallic materials such as black, non-ferrous metals and thermoplastics, and for deburring of metal die casting and plastic parts. Because of its high processing efficiency and low direct cost for production, it is especially suitable for large-scale continuous production environment. It is an ideal efficient processing equipment for large-scale industrial production.

Freezing trimming method

The thickness of the flash (or burr) of rubber, plastic products, zinc magnesium aluminum alloy and other products is much thinner than that of the products, so the embrittlement speed of the flash (or burr) is faster than that of the products. In the period when the flash (or burr) is embrittlement and the products are not embrittlement, the frozen deburring (trimming) machine strikes the products by shooting projectiles, so as to remove the products in embrittlement The flash (or burr) of. The frozen deburring (trimming) machine is a kind of quick embrittlement of rubber, plastic products, zinc magnesium aluminum alloy flash by using the ultra-low temperature of liquid nitrogen. In this state, the frozen particles ejected at high speed impact the product’s burr (or Flash), so as to not only remove the product’s burr (or Flash) with high quality and efficiency, but also keep all of the product itself Special deburring (trimming) equipment with unchanged physical properties. It can greatly improve the trimming (deburring) accuracy of products and has a high degree of intensification. This kind of equipment has become an indispensable equipment for finishing and deburring of precision rubber and plastic products and die-casting enterprises.

magnetic force method

The magnetic deburring machine uses its unique magnetic field distribution to produce strong and stable magnetic induction effect, so that the magnetic steel needle (imported raw materials. Semi permanent) and the workpiece can be fully ground in all directions and from multiple angles, so as to achieve the functions of rapid rust removal, dead angle removal, deburring and cutting edge removal, oxide film removal and sintering trace removal. Especially for complex shape, multi hole seam, internal and external thread and other workpieces, it can show its magic and magic effect, and it does not damage the surface of workpieces and affect the precision of workpieces. Let the work piece become smooth and clean in an instant, a new look. It is suitable for grinding, polishing and deburring of metal parts such as gold, silver, copper, aluminum, zinc, magnesium, iron, stainless steel and non-metal parts such as hard plastics.

Manipulator method

It is a typical mechanical and electrical integration device, which comprehensively uses the latest research results of machinery and precision machinery, microelectronics and computer, automatic control and drive, sensors and information processing, artificial intelligence and other disciplines. With the development of economy and the improvement of automation requirements in all walks of life, deburring manipulator technology has developed rapidly, and a variety of Deburring manipulator products. The practicality of deburring manipulator not only solves many practical problems which are difficult to solve by manpower alone, but also promotes the process of industrial automation.

Typical parts of deburring manipulator are: aluminum hub, frequency converter housing, synchronizer housing, synchronizer gear hub, bearing cover, cylinder block, valve body, valve cover, output shaft, engine gear, etc.

Automatic deburring and grinding brush

The fibre brush can withstand operating temperatures up to 150 ° C. It works even without coolant. In addition, the abrasive brush has strong water resistance, which will not be affected by the coolant. It can remove the burr of workpiece, especially for the thin workpiece and the edge of workpiece.

Surface grinding: grinding of pipes, joints, and shafts. The burr of inner hole in the process of stamping or laser processing can be removed by grinding brush, so as to keep multiple edges of precision metal parts of automobile free from burr.a