So?uk Ba?l?k Nedir?

Cold heading involves forming a piece of metal by applying pressure that exceeds its elastic limit. It is most commonly used for steel and stainless steel, which are popular for their strength and corrosion resistance. The process results in a dense product with an excellent surface finish. Some of the advantages of cold heading include a more uniform surface finish and less metal inclusion. While this process involves a higher level of detail than hot heading, it involves minimal waste. For this reason, it is often the preferred choice of many companies and manufacturers. This article will discuss the process and its uses, as well as costs and machines.

Process

Cold heading is the process of reducing the diameter of a thick bar. The process produces a bolt head with a hole in the center, and a screw head with a hole in the center. It can reduce material up to two percent of its diameter. The maximum number of diameters allowed in a bolt head depends on the material.

Cold heading is a simple process that allows for great versatility. The process can be automated for high-volume production and is highly efficient. The process also enables high-volume output of consistent parts. As with any type of metalworking process, choosing high-quality raw materials is key. The design and shape of the fastener are also important. Different types of heads are available, including hexagonal, round, and square, as well as radial slots and slits. Other options include multi-meter extrusion and automated feeding.

Cold heading tools are an essential part of the process. Meetyou Carbide provides a comprehensive range of cold heading tools for a wide variety of applications. The company also specializes in carbide tools for cold heading like carbide cold heading die.

Uygulamalar

Cold heading is a process that uses high-speed automated part formers to transform a simple wire into an intricately designed part. The process can produce parts at up to 400 pieces per minute. The process starts with a defined length of wire placed inside a die, and the material is extruded into the desired shape.

The cold heading process has many benefits. It produces very little waste and increases tensile strength, toughness, and fatigue resistance. It also improves the grain structure of the finished part, and increases design versatility. It is an effective and cost-effective process, which yields high strength parts from non-heat-treatable steel.

Cold heading produces parts in several types, including simple fasteners. It is a multi-station, automated process that can create various composite fasteners and components. Cold heading is a process that has evolved over time, with cold heading equipment being able to cold form more advanced metals.

Cold heading is a versatile and cost-effective process for creating complex shapes. It can be automated, and it can be used in high-volume operations. The quality of finished products depends on quality raw materials. Also, the design of the head is vital. A variety of head shapes, including hexagonal, round, and square, as well as radial slots, collars, and slits, are available.

Costs

The process of cold heading is a popular choice for high-volume parts containing difficult-to-machine materials. Its benefits over other metal forming processes include improved strength, tolerances, and quality. Cold heading uses very little scrap or offal, and its high efficiency means less material, energy, time, and manpower are used. Therefore, the costs of cold heading are low.

Cold-formed parts are cheaper per piece than products produced by other methods, such as screw machining. Cold-heading machinery has greater throughput capabilities – it can produce 90-300 parts per minute compared to five to 30 parts per minute with screw machining. Also, cold forming reduces energy, waste, and recycling costs, and can produce parts faster than other forming processes.

Cold heading is a highly automated process involving multiple operations. The tooling process involves a series of tools and dies that reshape a steel blank into a finished product. This means that the volume of the steel is unchanged, while its overall tensile strength is increased.

In cold heading, steel is rearranged by using punches and dies to produce a complex part. The process involves very low material loss, and it’s typically done in conjunction with other cold forming operations. Cold headed parts are used in thousands of products around the world.

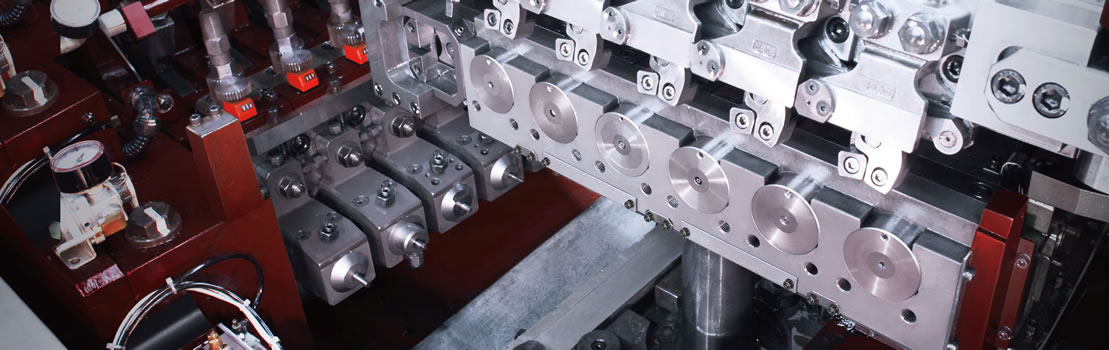

Machines

Cold heading is a forming process that makes metal pieces thinner than other types of metalworking processes. The process is a combination of hammers and dies. The hammer forces the material to be compressed into the tooling, which then forces it through a smaller orifice. This process also reduces the material’s diameter and length. Cold heading machines are more expensive and larger than other metalworking processes, but can produce pieces of very different thicknesses and complexities.

Cold heading is an efficient way to produce parts with a high strength-to-weight ratio. The process involves multiple processes that can result in highly accurate parts. First, the wire is annealed, which reduces its risk of cracking. Next, it is pulled through a hole in a box that reduces the wire to the desired size. This process ensures high accuracy and minimizes scrap.

Cold heading machines are ideal for manufacturing parts that require high precision. These parts are made from high quality alloy. This alloy provides a good wear-resistance and a long service life for the parts. Cold heading machines can also be customized according to specific client requirements. The design and layout of a cold heading machine is very important.

Cold heading is a manufacturing method that uses cold forming techniques to form metal parts. This process produces parts with a higher strength and increased grain flow. Machines that use cold heading have specialized dies and hammers that form the wire into the shape that the manufacturer requires.

Wire quality

The quality of wire used for cold heading is critical to the successful completion of a cold heading job. In particular, the grain size of steel wires has a significant impact on their cold heading performance. Too-fine a grain size increases the tensile strength and yield strength of the wire, which is undesirable for cold heading.

The cold heading process increases the cross-sectional area of the initial material by reducing the height of the work piece. The resulting part is larger in diameter and shorter in length than the original wire blank. The end result is a part that is more than two-thirds of its original diameter.

Generally, wire forming is based on one of two methods: wet drawing and dry drawing. Both methods involve pulling raw materials through a die block to reduce the size of the wire. When purchasing wire, it is necessary to consider its outer diameter and inner diameter, as well as its elemental purity. The wire is then wound on a spool for shipping and handling, and pre-straightening devices are used to correct any kinks or bends.

Cold heading is a highly productive process. It uses punch and dies to transform steel wire rod into fasteners with different shapes. The process also regularly follows the quenching and tempering process.

Equipment

Cold heading equipment helps in improving the strength-to-weight ratio of a finished part. This is because the grain flow remains uninterrupted, unlike the conventional cutting process. This process also helps in reducing scrap. The surface finish is also enhanced. A wide range of cold heading equipment is available to satisfy different needs and applications.

Cold heading equipment is designed to form wire into a variety of complex shapes. The process is automated and uses a hammer and reciprocating ram to force the wire into a preformed die. These machines are capable of producing up to 400 pieces per minute. To use a cold header, the wire is placed into a preformed die and is then upset or extruded into the shape required.

Cold heading equipment has evolved from a crude method of cold forming fasteners to a modern multi-station process that produces complex fasteners. Today, cold heading equipment allows for the production of components, composite fasteners, and other products with lower production costs. And with today’s technological advancements, cold heading equipment is able to cold form much tougher metals and can also cold form other materials.

Cold heading is an efficient and straightforward process that allows for a high-quality end product. Some machines feature automatic feeding, which allows for high-volume output of consistent parts. The quality of the end products is dependent on the quality of the raw materials, so the design of the fastener is also critical. There are many different types of heads available, including hexagonal, round, square, radial slot, collar, and slit.