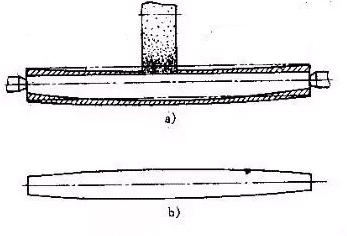

?ekil 1'de g?sterildi?i gibi. Genellikle a??nd?r?c?lar?n i?lem i?in kullan?lmas?na ta?lama makinesi denir. Yayg?n olarak kullan?lan ta?lama tak?mlar?, birle?tirilmi? ta?lama tak?mlar? (ta?lama ?ark?, ya? ta?? vb. gibi) ve kaplamal? ta?lama tak?mlar?d?r (a??nd?r?c? bant, a??nd?r?c? bez vb.). Farkl? i?leme ama?lar?na g?re ta?lama makineleri silindirik ta?lama, i? ta?lama ve yüzey ta?lama olarak ayr?labilir.

Figure 1 Grinding

Characteristic Elements of Grinding Wheel

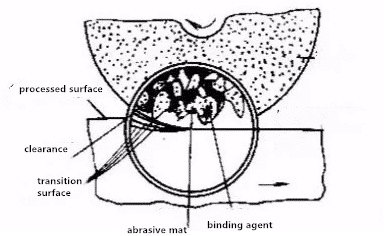

The grinding wheel is a porous body made by pressing and sintering a certain proportion of granular abrasives and binders with high hardness. Whether the selection of grinding wheel and grinding wheel is reasonable or not is very important. Whether the grinding wheel can achieve high processing quality and productivity is the main factor for its performance. It depends on the factors such as abrasive, particle size, binder, hardness, structure, shape, and size of grinding wheel. These are called characteristic elements of grinding wheels. As shown in Figure 2.

Figure 2 Grinding wheel

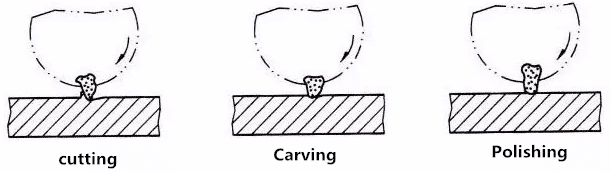

The cutting process of abrasive particles

The essence of the grinding process (as shown in Fig. 3) is a comprehensive process of cutting, scratching and friction polishing, from which a smaller surface roughness can be obtained. Cutting is the main role in rough grinding while cutting and friction polishing coexist in fine grinding.

(1) The abrasive grains with higher protrusion height and sharper edge on the surface of the grinding wheel cut deeper into the workpiece and produce chips, which play a cutting role (Fig. a).

(2) Small and blunt abrasive particles can only depict fine grooves on the surface of the workpiece, and the workpiece material is pushed toward both sides to uplift. At this time, there is no obvious chip generation, but only the scratching effect (fig. b).

(3) Comparing the concave and passivated abrasive particles, they are neither cut nor carved, but can only skip over the surface of the workpiece and play the role of friction polishing (Fig. c).

Figure 3 Grinding process of abrasive particles

Characteristics of Grinding Technology

High accuracy and low surface roughness

When grinding, there are many cutting edges on the surface of the grinding wheel, and the radius of the edge arc is small. Sharper on abrasives

The cutting edge can cut a very thin layer of metal, and the cutting thickness can be as small as several microns, which is one of the necessary conditions for precision machining.

The grinding machine used in grinding has higher accuracy, better rigidity, and stability than the general cutting machine tool, and has a micro-feed mechanism, which can carry out micro-cutting, thus ensuring the realization of precision machining.

When grinding, the cutting speed is very high. When the abrasive particles are cut from the workpiece surface at high cutting speed, there are many cutting edges for cutting. Each grinding edge only cuts a very small amount of metal from the workpiece, and the height of the residual area is very small, which is conducive to the formation of a smooth surface.

The processing accuracy is IT7-IT6, and the Ra value of surface roughness is 0.2-0.8 M.

Grinding wheel has a self-sharpening effect

In the grinding process, the self-sharpening effect of the grinding wheel is the cutting edge of general cutting tools that other cutting tools do not have. If blunt damage occurs, the cutting can not continue and must be changed or reground. Because of the self-sharpening of the grinding wheel, the abrasive particles can cut the parts with a sharper edge. In practical production, this principle is sometimes used for continuous grinding to improve the efficiency of grinding.

In the grinding process, under the action of high speed, high pressure and high temperature, the abrasives will gradually wear and become round and blunt. The cutting ability of the round and blunt Abrasives will decrease, and the force acting on the abrasives will increase continuously. When this force exceeds the abrasive strength limit, the abrasive particles will break up and produce new sharp edges and corners to replace the old round blunt abrasive particles for grinding; when this force exceeds the bonding force of the wheel binder, the round blunt abrasive particles will fall off from the surface of the wheel, revealing a fresh sharp layer of abrasive particles, and continue grinding.

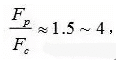

Back grinding force Fp is larger

Figure 4 Total grinding force and its decomposition

As shown in Fig. 4, the force acting on the workpiece by the grinding wheel during grinding is the total grinding force F. F can be decomposed into three vertical forces, namely grinding force Fc, back force Fp and feed grinding force Ff. In grinding, because of the small amount of back feed, the grinding force Fc is smaller, and the feed grinding force Fc is smaller, which is generally negligible. But the back grinding force Fp is very large.

This is because the grinding wheel has a large width and the abrasive particles are cut at a large negative rake angle. In the cutting process of cutting tools, the cutting force Fc is the largest in general, while the back grinding force Fp is the largest in grinding, which is a remarkable feature of grinding.

Influences: Fp acts on the direction of grinding wheel entry, the grinding wheel pushes the workpiece with great force, accelerates the passivation of the grinding wheel, causes bending deformation of the grinding wheel shaft and workpiece, and the workpiece is prone to cylindricity error, which directly affects the shape accuracy and surface quality of the workpiece, as shown in Fig. 5.

Fig. 5 Workpiece Deformation before and after Grinding

Solution: To eliminate or reduce the shape error caused by Fp, we adopt fine grinding, increase the number of times of polishing, or use auxiliary support.

Smoothing: When the workpiece is ground close to the final size (the allowance is usually 0.005-0.01mm), it will no longer grind with a knife. Polishing can improve the shape accuracy of workpiece and reduce surface roughness. The grinding quality increases with the increase of grinding times.

High Grinding Temperature

The grinding speed is high, which is 1020 times higher than that of general cutting, and is negative rake angle cutting. At such high cutting speed, the energy consumed in the three stages of grinding, slip, scratch and cutting is extremely large, and the friction is serious. Locally converted into heat, coupled with more abrasives, and because the heat transfer of grinding wheel itself is very poor, a large amount of grinding heat can not be spread out in a short time, the grinding zone forms instantaneous high temperature, and most of the grinding heat will be transferred to the parts. Generally, 80% of the cutting heat is transferred to the workpiece (the cutting tool is less than 20%) and instantaneously gathers on the surface of the workpiece, forming a large temperature gradient. The surface temperature of the workpiece can be as high as 1000 C, while the surface layer below 1mm is close to room temperature. When the local temperature is very high, the surface is prone to thermal deformation, even burns. Therefore, a large amount of cutting fluid should be applied to reduce the grinding temperature.

Surface deformation strengthening and serious residual stress

Compared with tool cutting, the surface deformation strengthening and residual stress layer of grinding are much shallower, but the degree is more serious. The processing technology, accuracy, and performance of parts are affected.

Solution: timely dressing grinding wheel with diamond tools, applying enough cutting fluid, increasing the number of polishing.

Application of Grinding

1) Cylindrical grinding:

Generally, in the ordinary cylindrical grinder or universal cylindrical grinder, cylindrical grinding has vertical, horizontal, comprehensive, deep grinding method, etc.

Longitudinal grinding method

Main Motion: High-Speed Rotation of Grinding Wheel

Circumferential feed motion: workpiece rotating motion;

Longitudinal feed motion: Reciprocating linear motion of workpiece and grinder table;

Horizontal feed motion: periodic cross feed of grinding wheel.

Characteristic: Small amount of grinding, small grinding force, less heat generated, better heat dissipation conditions. Good machining accuracy and surface quality. It has strong adaptability and low productivity.

Application: Single piece small batch production, fine grinding, especially the grinding of slender shaft. It is used most in practice.

Transverse grinding method

Cutting motion: The workpiece does not move longitudinally, and the grinding wheel feeds continuously and horizontally at a slow speed.

Characteristics: High productivity. Workpiece and grinding wheel contact area is large, grinding force are larger, heat is more, grinding temperature is higher, the workpiece is prone to deformation and burns.

Application: Batch and mass production, especially the forming surface of a workpiece. Workpiece with less wide machined surface and better rigidity. Shaft grinding.

Comprehensive grinding method

First, the workpiece surface is roughly ground by the cross grinding method. There is 5-10 mm lap between two adjacent sections, leaving 0.0l-0.03mm margin on the workpiece. Then, the workpiece is finely ground by the longitudinal grinding method.

The advantages of cross grinding and longitudinal grinding are synthesized.

Deep grinding

When grinding, all the allowances are removed in one stroke with a smaller longitudinal feed and a larger back feed (generally about 0.3 mm).

The front cone surface is roughly ground, and the cylindrical part is finely ground and polished.

Application: In mass production, the workpiece with larger stiffness is processed, and the two ends of the machined surface are far apart, allowing the grinding wheel to cut in and out.

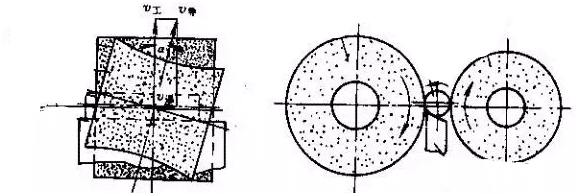

2) Grinding the outer circle on a centerless cylindrical grinder

Figure 7 Centerless Cylindrical Grinding

When grinding, the workpiece is placed between two grinding wheels, supported by a bracket underneath, without top support. The smaller one is made of rubber binder and the abrasive grains are thicker. It is called the guide wheel. The other one is used to grind workpiece, which is called grinding wheel. The guide wheel axis inclines one angle relative to the grinding wheel axis, rotates at a much slower speed than the grinding wheel, and drives the workpiece to rotate by friction force. On the one hand, the workpiece rotates to make circular feed, on the other hand, it makes axial feed motion, as shown in Fig. 7.

Centerless cylindrical grinder features:

The two ends of the workpiece need not punch the central hole beforehand, so the installation is more convenient.

After the machine tool is adjusted, it can be processed continuously, which is easy to realize automation and has high production efficiency.

The workpiece is clamped between two grinding wheels, and will not be bent because of the back grinding force, which is conducive to the grinding of slender shaft parts.

Centerless cylindrical grinding requires that the workpiece’s outer surface must be continuous on the circumference. If there is a long keyway or plane on the cylindrical surface, the guide wheel will not be able to drive the workpiece to rotate continuously, so it can not be ground.

Because the workpiece is supported on the bracket and positioned on its own cylindrical surface, if the workpiece with holes is ground, the coaxial between the cylindrical surface and the hole can not be guaranteed.

The adjustment of centerless cylindrical grinder is complicated.

3) Grinding of Holes

It can be carried out either on an internal grinder or on a universal external grinder. It can process cylindrical holes, conical holes and formed inner surfaces, etc. Grinding process:

When grinding cylindrical holes longitudinally, the workpiece is installed on the chuck and rotates in a reciprocating straight line along the axis. The grinding wheel rotates at high speed and periodically feeds horizontally.

If the conical hole is ground, only half of the conical angle of the head frame of the grinder is deflected horizontally.

4) Plane grinding

Peripheral grinding: grinding with the outer surface of the grinding wheel.

Features: Small contact area between grinding wheel and workpiece, good heat dissipation, cooling and chip removal, and high processing quality.

Application: Processing workpieces with high-quality requirements.

Equipment: Horizontal axis surface grinder.

End grinding: grinding with the end face of the grinding wheel.

Characteristic: The grinding head has a shorter extension length and better rigidity. It is allowed to use a larger grinding dosage and has higher productivity. However, the contact area between grinding wheel and workpiece is large, heat generation is large, cooling is difficult, and processing quality is low.

Application: Workpiece with low-quality requirement is replaced by milling as pre-processing before grinding.

Equipment: Vertical axis surface grinder.

Development Direction of Grinding

High Precision and Small Roughness Grinding

Such as precision grinding, ultra-precision grinding, mirror grinding.

Requirements: Grinding machine accuracy, motion stability, reasonable process parameters, grinding wheel fine dressing. Grinding process: When grinding, the micro-edge of abrasive particles cuts micro-chips on the workpiece surface. At the same time, under appropriate grinding pressure, with the help of semi-blunt micro-edge, friction polishing effect is produced on the workpiece surface, thus achieving high accuracy and small surface roughness.

High-Speed Grinding

Grinding speed VC (> 50m/s). Increase metal removal rate and productivity by increasing workpiece speed. Because of the high grinding speed, the number of abrasive particles passing through the grinding zone in a unit time increases, the thickness of the cutting layer of each abrasive particle will become thinner, the cutting load will be reduced, and the durability of the grinding wheel will be significantly improved.

Because the thickness of the cutting layer of each abrasive is small, the height of the residual area of the workpiece surface is small,

and the uplift height formed by the abrasive scratching is also small during high-speed grinding, so the roughness of the grinding surface is small. And the back force of high-speed grinding decreases correspondingly, which is helpful to ensure the processing accuracy of the workpiece (especially the workpiece with poor stiffness).

Powerful grinding

Grinding with large back feed and small longitudinal feed speed, also known as slow-forward deep grinding or deep grinding. It is suitable for processing various shaped surfaces and grooves, especially for grinding difficult-to-machine materials (such as heat-resistant alloys). It can grind the required parts directly from the casting and forging blanks, and productivity is greatly improved. Both high-speed grinding and strong grinding require higher requirements for machine tools, grinding wheels and cooling methods.

Abrasive Belt Grinding

Equipment is generally relatively simple. Belt rotation is the main movement. The workpiece is fed by conveyor belt. Workpiece passes through the grinding area above the supporting plate, that is to say, the processing is completed.

Abrasive belt grinding has become one of the development directions of grinding because of its high production efficiency, good processing quality and easy grinding of complex surfaces.