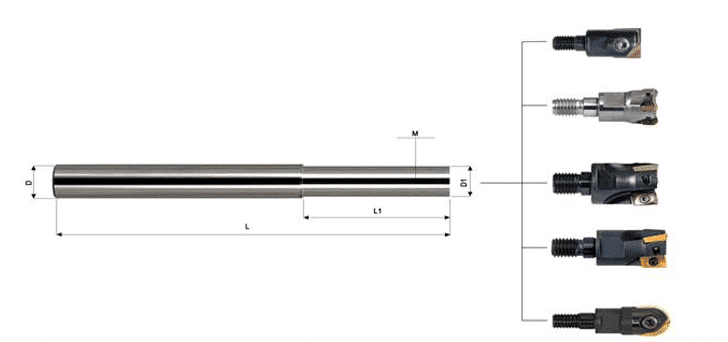

?plikli Silindirik Karbür Uzatma ?aft

Kat? Tungsten Karbür Uzatma ?aft, vidal? modüler parmak frezeler i?in yayg?n olarak kullan?l?r ve titre?im ?nleyici ?zelli?i, vidal? modüler parmak frezenin ?mrünü etkili bir ?ekilde art?rabilir ve daha do?ru frezeleme kapasitesi sa?layabilir.

sinterleme

KAL?A.

Geli?mi? bilgisayar kontrollü HIP f?r?nlar? sinterleme i?lemi s?ras?nda daha yo?un bir yap? elde etmek i?in daha fazla bas?n? sa?lamak üzere uygulan?r.

Pudra

Mükemmel.

Almanya HCStarck ile derin i?birli?imiz sayesinde, karbür ?ubuk üretimi i?in tüm standart kalitelerimiz i?in dünyadaki karbür ?ubuk i?in en iyi tozu kullan?yoruz.

Konu

Conection

Karbür uzatma mili de?i?tirilebilir modüler parmak frezelere vidalanabilir ve titre?im ?nleyici ?zelli?i daha uzun tak?m ?mrü ve son derece iyi yüzey sa?layabilir?biti?.

Standart ?l?ü

kod

OD

?D

uzunluk

12-100-M6

12

M6

100

12-150-M6

12

M6

150

16-100-M8

16

M8

100

16-150-M8

16

M8

150

16-200-M8

16

M8

200

16-250-M8

16

M8

250

16-300-M8

16

M8

300

20-100-M10

20

M10

100

20-150-M10

20

M10

150

20-200-M10

20

M10

200

20-250-M10

20

M10

250

20-300-M10

20

M10

300

25-150-M12

25

M12

150

25-200-M12

25

M12

200

25-250-M12

25

M12

250

25-300-M12

25

M12

300

32-150-M16

32

M16

150

32-200-M16

32

M16

200

32-250-M16

32

M16

250

32-300-M16

32

M16

300

32-350-M16

32

M16

350

32-400-M16

32

M16

400

OEM Mü?teri servisi

Gereksinimlerinize g?re notlar geli?tirebilir ve ?iziminizle ayn? ?ekli yapabiliriz. Lazer markalama ve n?tr paketi de avantajlar?n?z i?in mevcuttur.

s?n?f

s?n?f

? MT20.8

ISO aral???

? K40-K50

WC + di?er karbür

%

85

e?

%

15

WC tane büyüklü?ü

um

0.8

yo?unluk

g /㎝3

13.95

sertlik

HV30

1350

?HD

? 89.5

enine kopma mukavemeti

N / mm

3800

kpsi

? 551

k?r?lma toklu?u

Mpa.m?

17.5

gencin modülü

kpsi

79086

bas?n? dayan?m?

kpsi

957

Ya? kanall? so?utucu Tungsten Karpit ?ubuklar

Hem düz so?utucu delikli karbür ?ubuk hem de sarmal so?utucu delikleri birlikte verilir. Stokta farkl? kaliteler de mevcuttur. Dahili so?utma deli?i ?ok daha verimli tala? tahliyesi ve daha derin delik olu?turma ?zellikleri sa?layabilir. Derin delikli matkaplarda ve iplik frezelerinde yayg?n olarak kullan?l?r.

tip

D (mm)

D (mm)

Delik sapmas?

position≤ (mm)

L (mm)

D

Tol.

d

Tol.

L

Tol.

OD4.0 x ID1.0 x 330

4.0

+0.2/+0.6

1.0

± 0.15

0.2

330

0/+5

OD5.0 x ID1.0 x 330

5.0

+0.2/+0.6

1.0

± 0.15

0.2

330

0/+5

OD5.0 x ID1.5 x 330

5.0

+0.2/+0.6

1.5

± 0.15

0.2

330

0/+5

OD6.0 x ID1.0 x 330

6.0

+0.2/+0.6

1.0

± 0.15

0.2

330

0/+5

OD6.0 x ID1.5 x 330

6.0

+0.2/+0.6

1.5

± 0.15

0.2

330

0/+5

OD8.0 x ID1.0 x 330

8.0

+0.2/+0.6

1.0

± 0.15

0.25

330

0/+5

OD8.0 x ID1.5 x 330

8.0

+0.2/+0.6

1.5

± 0.15

0.25

330

0/+5

OD9.0 x ID1.0 x 330

9.0

+0.3/+0.7

1.0

± 0.15

0.25

330

0/+5

OD10.0 x ID1.0 x 330

10.0

+0.3/+0.7

1.0

± 0.15

0.25

330

0/+5

OD10.0 x ID2.0 x 330

10.0

+0.3/+0.7

2.0

± 0.2

0.25

330

0/+5

OD11.0 x ID1.0 x 330

11.0

+0.3/+0.7

1.0

± 0.15

0.25

330

0/+5

OD12.0 x ID1.0 x 330

12.0

+0.3/+0.7

1.0

± 0.15

0.25

330

0/+5

OD12.0 x ID2.0 x 330

12.0

+0.3/+0.7

2.0

± 0.2

0.25

330

0/+5

OD14.0 x ID2.0 x 330

14.0

+0.3/+0.7

2.0

± 0.2

0.25

330

0/+5

OD16.0 x ID2.0 x 330

16.0

+0.4/+0.8

2.0

± 0.2

0.25

330

0/+5

OD16.0 x ID3.0 x 330

16.0

+0.4/+0.8

3.0

± 0.25

0.25

330

0/+5

OD18.0 x ID3.0 x 330

18.0

+0.4/+0.8

3.0

± 0.25

0.3

330

0/+5

OD20.0 x ID3.0 x 330

20.0

+0.4/+0.8

3.0

± 0.25

0.3

330

0/+5

20.0≤Dia≤40.0 istek üzerine temin edilebilir

20.0≤Dia≤40.0 istek üzerine temin edilebilir

tip

D (mm)

TK (mm)

D (mm)

Delik konumunun sapmas?≤ (mm)

L (mm)

D

Tol. (Aa)

TK

Tol.

d

Tol. (Aa)

L

Tol. (Aa)

OD4.3 x 2ID0.8 x 1.8 x 330

4.3

0/+0.6

1.8

-0.4/0

0.8

± 0.10

0.15

330

0/+10

OD5.3 x 2ID0.8 x 2.0 x 330

5.3

0/+0.6

2.0

-0.4/0

0.8

± 0.10

0.20

330

0/+10

OD6.3 x 2ID1.0 x 3.0 x 330

6.3

0/+0.6

3.0

-0.5/0

1.0

± 0.15

0.20

330

0/+10

OD7.3 x 2ID1.0 x 3,5 x 330

7.3

0/+0.6

3.5

-0.5/0

1.0

± 0.15

0.20

330

0/+10

OD8.3 x 2ID1.0 x 4.0 x 330

8.3

0/+0.6

4.0

-0.6/0

1.0

± 0.15

0.20

330

0/+10

OD9.3 x 2ID1.4 x 4.0 x 330

9.3

0/+0.6

4.0

-0.6/0

1.4

± 0.15

0.20

330

0/+10

OD10.3 x 2ID1.4 x 5.0 x 330

10.3

0/+0.6

5.0

-0.6/0

1.4

± 0.15

0.20

330

0/+10

OD11.3 x 2ID1.4 x 5.0 x 330

11.3

0/+0.6

5.0

-0.6/0

1.4

± 0.15

0.28

330

0/+10

OD12.3 x 2ID1.75 x 6.0 x 330

12.3

0/+0.6

6.0

-0.6/0

1.75

± 0.15

0.30

330

0/+10

OD13.3 x 2ID1.75 x 6.0 x 330

13.3

0/+0.6

6.0

-0.6/0

1.75

± 0.15

0.34

330

0/+10

OD14.3 x 2ID1.75 x 7.0 x 330

14.3

0/+0.6

7.0

-0.6/0

1.75

± 0.15

0.37

330

0/+10

OD15.3 x 2ID2.0 x 7.0 x 330

15.3

0/+0.6

7.0

-0.6/0

2.0

± 0.20

0.37

330

0/+10

OD16.3 x 2ID2.0 x 8.0 x 330

16.3

0/+0.6

8.0

-0.6/0

2.0

± 0.20

0.40

330

0/+10

OD17.3 x 2ID2.0 x 8.0 x 330

17.3

0/+0.8

8.0

-0.6/0

2.0

± 0.20

0.47

330

0/+10

OD18.3 x 2ID2.0 x 9.0 x 330

18.3

0/+0.8

9.0

-0.6/0

2.0

± 0.20

0.50

330

0/+10

OD19.3 x 2ID2.0 x 9.0 x 330

19.3

0/+0.8

9.0

-0.6/0

2.0

± 0.20

0.50

330

0/+10

OD20.3 x 2ID2.5 x 10.0 x 330

20.3

0/+0.8

10.0

-0.8/0

2.5

± 0.25

0.50

330

0/+10

tip

D (mm)

D (mm)

Tk

bir

Saha

D

Ho?g?rü

d

Ho?g?rü

TK

Ho?g?rü

P1

P2

P3

Ho?g?rü

OD3.3 x 2ID0.4 x 1.7 x 330

3.3

2.33

0.4

± 0.10

1.7

0/-0.3

≤0.08

15.89

16.32

16.77

± 0.23

OD4.3 x 2ID0.6 x 2.2 x 330

4.3

2.33

0.6

± 0.15

2.2

0/-0.3

≤0.10

21.19

21.77

22.36

± 0.31

OD5.3 x 2ID0.7 x 2.6 x 330

5.3

2.67

0.7

± 0.15

2.6

0/-0.4

≤0.13

26.49

27.21

27.95

± 0.38

OD6.3 x 2ID0.7 x 2.6 x 330

6.3

2.5

0.7

± 0.15

2.6

0/-0.4

≤0.15

31.79

32.65

33.54

± 0.46

OD6.3 x 2ID1.0 x 2.6 x 330

6.3

2.5

1.0

± 0.15

2.6

0/-0.4

≤0.15

31.79

32.65

33.54

± 0.46

OD7.3 x 2ID1.0 x 3.7 x 330

7.3

2.5

1.0

± 0.15

3.7

0/-0.4

≤0.15

37.09

38.09

39.13

± 0.54

OD8.3 x 2ID1.0 x 4.0 x 330

8.3

2.5

1.0

± 0.15

4.0

0/-0.4

≤0.15

42.38

43.53

44.73

± 0.62

OD8.3 x 2ID1.0 x 3,5 x 330

8.3

2.5

1.0

± 0.15

3.5

0/-0.4

≤0.15

42.38

43.53

44.73

± 0.62

OD8.3 x 2ID0.6 x 2.8 x 330

8.3

2.5

0.6

± 0.15

2.8

0/-0.4

≤0.15

42.38

43.53

44.73

± 0.62

OD9.3 x 2ID1.4 x 4.8 x 330

9.3

2.5

1.4

± 0.15

4.8

0/-0.6

≤0.20

47.68

48.97

50.32

± 0.69

OD10.3 x 2ID1.4 x 4.8 x 330

10.3

2.75

1.4

± 0.15

4.8

0/-0.6

≤0.20

52.98

54.41

55.91

± 0.77

OD10.3 x 2ID0.7 x 2.6 x 330

10.3

2.75

0.7

± 0.15

2.6

0/-0.4

≤0.20

52.98

54.41

55.91

± 0.77

OD10.3 x 2ID1.0 x 3.0 x 330

10.3

2.75

1.0

± 0.15

3.0

0/-0.4

≤0.20

52.98

54.41

55.91

± 0.77

OD10.3 x 2ID1.4 x 5.0 x 330

10.3

2.75

1.4

± 0.15

5.0

0/-0.6

≤0.20

52.98

54.41

55.91

± 0.77

OD11.3 x 2ID1.4 x 5.3 x 330

11.3

2.75

1.4

± 0.15

5.3

0/-0.8

≤0.28

58.28

59.86

61.5

± 0.85

OD12.3 x 2ID1.4 x 6.25 x 330

12.3

2.75

1.4

± 0.15

6.25

0/-0.8

≤0.30

63.58

65.3

67.09

± 0.92

OD12.3 x 2ID1.75 x 6.0 x 330

12.3

2.75

1.75

± 0.20

6.0

0/-0.8

≤0.30

63.58

65.3

67.09

± 0.92

OD13.3 x 2ID1.75 x 6.5 x 330

13.3

3.0

1.75

± 0.20

6.5

0/-0.8

≤0.34

68.87

70.74

72.68

± 1.00

OD14.3 x 2ID1.75 x 7.1 x 330

14.3

3.5

1.75

± 0.20

7.1

0/-0.8

≤0.37

74.17

76.18

78.27

± 1.08

OD14.3 x 2ID0.8 x 3,5 x 330

14.3

3.5

0.8

± 0.15

3.5

0/-0.4

≤0.37

74.17

76.18

78.27

± 1.08

OD14.3 x 2ID1.4 x 4.5 x 330

14.3

3.5

1.4

± 0.15

4.5

0/-0.6

≤0.37

74.17

76.18

78.27

± 1.08

OD15.3 x 2ID1.75 x 7.7 x 330

15.3

3.5

1.75

± 0.20

7.7

0/-0.8

≤0.40

79.47

81.62

83.86

± 1.15

OD16.3 x 2ID1.75 x 8.3 x 330

16.3

3.5

1.75

± 0.20

8.3

0/-0.8

≤0.40

84.77

87.06

89.45

± 1.23

OD16.3 x 2ID2.0 x 8.0 x 330

16.3

3.5

2.0

± 0.20

8.0

0/-0.6

≤0.40

84.77

87.06

89.45

± 1.23

OD17.3 x 2ID1.75 x 8.9 x 330

17.3

3.5

1.75

± 0.20

8.9

0/-0.8

≤0.47

90.07

92.5

95.04

± 1.31

OD18.3 x 2ID2.0 x 9.55 x 330

18.3

3.5

2.0

± 0.25

9.55

0/-0.8

≤0.50

95.36

97.95

100.63

± 1.38

OD18.3 x 2ID1.75 x 9.15 x 330

18.3

3.5

1.75

± 0.20

9.15

0/-0.8

≤0.50

95.36

97.95

100.63

± 1.38

OD19.3 x 2ID2.0 x 10 x 330

19.3

3.5

2.0

± 0.25

10.0

0/-0.8

≤0.50

100.66

103.39

106.22

± 1.46

OD20.3 x 2ID2.0 x 10.4 x 330

20.3

3.5

2.0

± 0.25

10.4

0/-1

≤0.50

105.96

108.83

111.81

± 1.54

Not: D18.3, L> 100, L Tolerans? 0 + 7; L <100, L Tolerans 0 ~ + 5.? D = 18.3, L Tolerans + 3 ~ + 10.

Not: D <18.3, L> 100, L Tolerans?0 ~ + 7, L <100, L Tolerans?0 ~ + 5, D≥18.3, Uzunluk Tolerans? + 3 ~ + 10

tip

D (mm)

D (mm)

TK (mm)

bir

Ptich

D

Tol.

d

Tol.

TK

Tol.

P 1

S 2

S 3

Tol.

OD6.3 x 2ID0.6 x 1.9 x LC

6.3

2.5

0.6

± 0.15

1.9

0/-0.4

≤0.15

18.20

18.85

19.52

± 0.34

OD6.3 x 2ID0.5 x 2.2 x LC

6.3

2.5

0.5

± 0.15

2.2

0/-0.4

≤0.15

21.68

22.46

23.28

± 0.42

OD8.3 x 2ID0.65 x 2.7 x LC

8.3

2.5

0.65

± 0.15

2.7

0/-0.6

≤0.15

28.91

29.95

31.04

± 0.56

OD10.3 x 2ID0.8 x 3.5 x LC

10.3

2.75

0.8

± 0.15

3.5

0/-0.8

≤0.20

36.14

37.44

38.8

± 0.70

OD12.3 x 2ID0.9 x 4.2 x LC

12.3

2.75

0.9

± 0.15

4.2

0/-0.8

≤0.30

43.37

44.93

46.55

± 0.84

OD14.3 x 2ID1.0 x 4.7 x LC

14.3

3.5

1.0

± 0.20

4.7

0/-0.8

≤0.37

50.6

52.42

54.31

± 0.98

OD16.3 x 2ID1.2 x 5.5 x LC

16.3

3.5

1.2

± 0.20

5.5

0/-0.8

≤0.40

57.82

59.9

62.07

± 1.12

OD18.3 x 2ID1.4 x 6.3 x LC

18.3

3.5

1.4

± 0.20

6.3

0/-0.8

≤0.50

65.05

67.39

69.83

± 1.26

OD20.3 x 2ID1.5 x 7.1 x LC

20.3

3.5

1.5

± 0.20

7.1

0/-1.0

≤0.50

72.28

74.88

77.59

± 1.40

Not: D <18.3, L> 100, L Tolerans? 0 ~ 7; L <100, L Tolerans 0 ~ + 5. D18.1, L Tolerans + 3 ~ + 10.

tip

D (mm)

D (mm)

TK

bir

Saha

D

Tol.

d

Tol.

TK

Tol.

P 1

S 2

S 3

Tol.

OD6.3 x 3ID0.5 x 2.9 x LB

6.3

2.5

0.5

± 0.15

2.9

0/-0.4

≤0.15

31.79

32.65

33.54

± 0.46

OD8.3 × 3ID0.7 × 4,0 × LB

8.3

2.5

0.7

± 0.15

4

0/-0.4

≤0.15

42.38

43.53

44.73

± 0.62

OD9.3 × 3ID0.7 × 4,0 × LB

9.3

2.5

0.85

± 0.15

5.1

0/-0.5

≤0.20

47.68

48.97

50.32

± 0.69

OD10.3 x 3ID0.85 x 5.1 x LB

10.3

2.75

0.85

± 0.15

5.1

0/-0.4

≤0.20

52.98

54.41

55.91

± 0.77

BФ12.3 x 3Ф1.1 x 6.3 x LB

12.3

2.75

1.1

± 0.15

6.3

0/-0.6

≤0.30

63.58

65.3

67.09

± 0.92

OD14.3 x 3ID1.4 x 7.3 x LB

14.3

3.5

1.4

± 0.20

7.3

0/-0.8

≤0.40

74.17

76.18

78.27

± 1.08

OD15.3 x 3ID1.4 x 7.3 x LB

15.3

3.5

1.4

± 0.20

7.8

0/-0.8

≤0.40

79.47

81.62

83.86

± 1.15

OD16.3 x 3ID1.6 x 8.3 x LB

16.3

3.5

1.6

± 0.20

8.3

0/-0.8

≤0.40

84.77

87.06

89.45

± 1.23

OD18.3 x 3ID1.7 x 9.5 x LB

18.3

3.5

1.7

± 0.20

9.5

0/-0.8

≤0.50

95.36

97.95

100.63

± 1.38

OD20.3 x 3ID1.9 x 10.2 x LB

20.3

3.5

1.9

± 0.25

10.2

0/-0.8

≤0.50

105.96

108.83

111.81

± 1.54

Not:? D <18.3, L> 100, L Tolerans0 ~ + 7, L <100, L Tolerans0 ~ + 5, D≥18.3, Uzunluk Tolerans? + 3 ~ + 10

tip

D (mm)

D (mm)

Tk

bir

Saha

D

Tol.

d

Ho?g?rü

TK

Tol.

P1

P2

P3

Tol.

OD6.3 x 3ID0.5 x 2.9 x LB

6.3

2.5

0.5

± 0.15

2.2

0/-0.4

≤0.15

21.68

22.46

23.28

± 0.42

OD8.3 × 3ID0.7 × 4,0 × LB

8.3

2.5

0.65

± 0.15

2.7

0/-0.4

≤0.15

28.91

29.95

31.04

± 0.56

OD10.3 x 3ID0.85 x 5.1 x LB

10.3

2.75

0.8

± 0.15

3.5

0/-0.4

≤0.20

36.14

37.44

38.8

± 0.70

BФ12.3 x 3Ф1.1 x 6.3 x LB

12.3

2.75

0.9

± 0.15

4.2

0/-0.6

≤0.30

43.37

44.93

46.55

± 0.84

OD14.3 x 3ID1.4 x 7.3 x LB

14.3

3.5

1.0

± 0.20

4.7

0/-0.6

≤0.37

50.60

52.42

54.31

± 0.98

OD16.3 x 3ID1.6 x 8.3 x LB

16.3

3.5

1.2

± 0.20

5.5

0/-0.8

≤0.40

57.82

59.90

62.07

± 1.12

OD18.3 x 3ID1.7 x 9.5 x LB

18.3

3.5

1.4

± 0.20

6.3

0/-0.8

≤0.50

65.05

67.39

69.83

± 1.26

OD20.3 x 3ID1.9 x 10.2 x LB

20.3

3.5

1.5

± 0.20

7.1

0/-0.8

≤0.50

72.28

74.88

77.59

± 1.40

sinterleme

KAL?A.

Geli?mi? bilgisayar kontrollü HIP f?r?nlar? sinterleme i?lemi s?ras?nda daha yo?un bir yap? elde etmek i?in daha fazla bas?n? sa?lamak üzere uygulan?r.

Pudra

Mükemmel.

Almanya HCStarck ile derin i?birli?imiz sayesinde, karbür ?ubuk üretimi i?in tüm standart kalitelerimiz i?in dünyadaki karbür ?ubuk i?in en iyi tozu kullan?yoruz.

So?utma

??.

Dahili so?utma deli?i ?ok daha verimli tala? tahliyesi ve daha derin delik olu?turma ?zellikleri sa?layabilir. Sadece düz so?utma s?v?s? de?il, ayn? zamanda spiral so?utma s?v?s? karbür ?ubu?u da tedarik ediyoruz.

OEM Mü?teri servisi

Gereksinimlerinize g?re notlar geli?tirebilir ve ?iziminizle ayn? ?ekli yapabiliriz. Lazer markalama ve n?tr paketi de avantajlar?n?z i?in mevcuttur.

s?n?f

| s?n?f | ? | MT09U | MT10S | MT12S | MT25S | MT06U | MT20.8 |

| ISO aral??? | ? | K10-K20 | K20-K40 | K20-K40 | K20-K40 | K05-K10 | K40-K50 |

| WC + di?er karbür | % | 91 | 90 | 88 | 88 | 93.5 | 85 |

| e? | % | 9 | 10 | 12 | 12 | 6.5 | 15 |

| WC tane büyüklü?ü | um | 0.4 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| yo?unluk | g / ㎝3 | 14.5 | 14.42 | 14.12 | 14.1 | 14.85 | 13.95 |

| sertlik | HV30 | 1890 | 1600 | 1580 | 1750 | 1890 | 1350 |

| ?HD | ? | 93.5 | 91.5 | 91.2 | 92.5 | 93.5 | 89.5 |

| enine kopma mukavemeti | N / mm | 3800 | 4100 | 4200 | 4400 | 3700 | 3800 |

| kpsi | ? | 590 | 609 | 638 | 540 | 551 | 551 |

| k?r?lma toklu?u | Mpa.m? | 10.2 | 14.2 | 14.7 | 13.5 | 10.1 | 17.5 |

| gencin modülü | kpsi | 86780 | 85360 | 80860 | 80000 | 91000 | 79086 |

| bas?n? dayan?m? | kpsi | 1145 | 1015 | 1010 | 1109 | 1156 | 957 |

s?n?f | ?zellikleri ve uygulamalar? |

MT09U? | 9%Co ile ultra ince taneli WC ?ok yüksek a??nma direnci ve mükemmel deformasyon direnci Yüksek kesme h?z? frezeleme, finisaj Sertle?tirilmi? ?elik, plastik, elyaf takviyeli malzemeler, HRC55-65 üzerinde kullan?m i?in |

MT10S? | 10%Co ile ultra ince taneli WC ?ok yüksek a??nma direnci ve mükemmel deformasyon direnci Yüksek kesme h?z? frezeleme ve delme Genel kullan?m i?in ve a?a??daki her türlü malzeme i?in uygundur |

MT12S? | 12%Co ile mikron alt? tane WC Yüksek tokluk ve a??nma direnci Paslanmaz ?eli?in i?lenmesi i?in ?zel olarak tasarlanm??t?r Paslanmaz ?elik, nikel bazl? ala??mlar, titanyum ala??m? ve ?zel ala??mlarda kullan?m i?in |

MT25S? | 12%Co ile ultra ince taneli WC ?ok yüksek tokluk ve yüksek a??nma direnci Yüzey i?lemleri, nikel ve nikel ala??mlar? i?in 45 ila 55HRC ?elikleri aras?nda sertli?e sahip ?eliklerin i?lenmesi ve kaba i?lemesi i?in uygundur |

MT06U? | 6% Co ile mikron alt? tane WC ?ok yüksek a??nma direnci Yüksek kesme h?z? Plastik kompozitler, PCB, seramik, ah?ap ve MDF'nin delinmesi ve frezelenmesi i?in |

MT20.8? | 15%Co ile mikron alt? tane WC Yüksek mukavemet ve tokluk Yüksek h?zl? delme Kat? karbür z?mbalarda kullan?m i?in |

Kat? Umround Tungsten Karbür ?ubuk Bo?luklar?

sinterleme

KAL?A.

Geli?mi? bilgisayar kontrollü HIP f?r?nlar? sinterleme i?lemi s?ras?nda daha yo?un bir yap? elde etmek i?in daha fazla bas?n? sa?lamak üzere uygulan?r.

Pudra

Mükemmel.

Almanya HCStarck ile derin i?birli?imiz sayesinde, karbür ?ubuk üretimi i?in tüm standart kalitelerimiz i?in dünyadaki karbür ?ubuk i?in en iyi tozu kullan?yoruz.

Teslim süresi

H?zl?.

Karbür ?ubuk imalat?n?n maksimum verimlili?i i?in ekstrüzyon, otomatik pres ve so?uk izostatik pres dahil ü? farkl? s?k??t?rma y?ntemi kullan?l?r.

Standart 330mm Uzunluk, Metrik, Birim Milimetre

|

?ap |

Ho?g?rü |

Uzunluk Tolerans? |

?ap |

Ho?g?rü |

Uzunluk Tolerans? |

?ap |

Ho?g?rü |

Uzunluk Tolerans? |

|

0.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

9.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

19.5 |

+0.20/+0.60 |

-0,0 / +10.0 |

|

1.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

10.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

20.0 |

+0.20/+0.60 |

-0,0 / +10.0 |

|

1.2 |

+0.20/+0.45 |

-0,0 / +10.0 |

10.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

20.5 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

1.6 |

+0.20/+0.45 |

-0,0 / +10.0 |

11.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

21.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

1.8 |

+0.20/+0.45 |

-0,0 / +10.0 |

11.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

22.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

2.3 |

+0.20/+0.45 |

-0,0 / +10.0 |

12.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

23.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

2.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

12.5 |

+0.20/+0.60 |

-0,0 / +10.0 |

24.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

3.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

13.0 |

+0.20/+0.60 |

-0,0 / +10.0 |

25.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

3.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

13.5 |

+0.20/+0.60 |

-0,0 / +10.0 |

26.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

4.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

14.0 |

+0.20/+0.60 |

-0,0 / +10.0 |

27.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

4.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

14.5 |

+0.20/+0.60 |

-0,0 / +10.0 |

28.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

5.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

15.0 |

+0.20/+0.60 |

-0,0 / +10.0 |

29.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

5.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

15.5 |

+0.20/+0.60 |

-0,0 / +10.0 |

30.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

6.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

16.0 |

+0.20/+0.60 |

-0,0 / +10.0 |

31.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

6.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

16.5 |

+0.20/+0.60 |

-0,0 / +10.0 |

32.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

7.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

17.0 |

+0.20/+0.60 |

-0,0 / +10.0 |

33.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

7.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

17.5 |

+0.20/+0.60 |

-0,0 / +10.0 |

34.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

8.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

18.0 |

+0.20/+0.60 |

-0,0 / +10.0 |

35.0 |

+0.20/+0.80 |

-0,0 / +10.0 |

|

8.5 |

+0.20/+0.45 |

-0,0 / +10.0 |

18.5 |

+0.20/+0.60 |

-0,0 / +10.0 |

|||

|

9.0 |

+0.20/+0.45 |

-0,0 / +10.0 |

19.0 |

+0.20/+0.60 |

-0,0 / +10.0 |

Minimum ?ap 0.3mm ve Maksimum ?ap 40mm

OEM Mü?teri servisi

Gereksinimlerinize g?re notlar geli?tirebilir ve ?iziminizle ayn? ?ekli yapabiliriz. Lazer markalama ve n?tr paketi de avantajlar?n?z i?in mevcuttur.

s?n?f

| s?n?f | ? | MT09U | MT10S | MT12S | MT25S | MT06U | MT20.8 |

| ISO aral??? | ? | K10-K20 | K20-K40 | K20-K40 | K20-K40 | K05-K10 | K40-K50 |

| WC + di?er karbür | % | 91 | 90 | 88 | 88 | 93.5 | 85 |

| e? | % | 9 | 10 | 12 | 12 | 6.5 | 15 |

| WC tane büyüklü?ü | um | 0.4 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| yo?unluk | g / ㎝3 | 14.5 | 14.42 | 14.12 | 14.1 | 14.85 | 13.95 |

| sertlik | HV30 | 1890 | 1600 | 1580 | 1750 | 1890 | 1350 |

| ?HD | ? | 93.5 | 91.5 | 91.2 | 92.5 | 93.5 | 89.5 |

| enine kopma mukavemeti | N / mm | 3800 | 4100 | 4200 | 4400 | 3700 | 3800 |

| kpsi | ? | 590 | 609 | 638 | 540 | 551 | 551 |

| k?r?lma toklu?u | Mpa.m? | 10.2 | 14.2 | 14.7 | 13.5 | 10.1 | 17.5 |

| gencin modülü | kpsi | 86780 | 85360 | 80860 | 80000 | 91000 | 79086 |

| bas?n? dayan?m? | kpsi | 1145 | 1015 | 1010 | 1109 | 1156 | 957 |

s?n?f | ?zellikleri ve uygulamalar? |

MT09U? | 9%Co ile ultra ince taneli WC ?ok yüksek a??nma direnci ve mükemmel deformasyon direnci Yüksek kesme h?z? frezeleme, finisaj Sertle?tirilmi? ?elik, plastik, elyaf takviyeli malzemeler, HRC55-65 üzerinde kullan?m i?in |

MT10S? | 10%Co ile ultra ince taneli WC ?ok yüksek a??nma direnci ve mükemmel deformasyon direnci Yüksek kesme h?z? frezeleme ve delme Genel kullan?m i?in ve a?a??daki her türlü malzeme i?in uygundur |

MT12S? | 12%Co ile mikron alt? tane WC Yüksek tokluk ve a??nma direnci Paslanmaz ?eli?in i?lenmesi i?in ?zel olarak tasarlanm??t?r Paslanmaz ?elik, nikel bazl? ala??mlar, titanyum ala??m? ve ?zel ala??mlarda kullan?m i?in |

MT25S? | 12%Co ile ultra ince taneli WC ?ok yüksek tokluk ve yüksek a??nma direnci Yüzey i?lemleri, nikel ve nikel ala??mlar? i?in 45 ila 55HRC ?elikleri aras?nda sertli?e sahip ?eliklerin i?lenmesi ve kaba i?lemesi i?in uygundur |

MT06U? | 6% Co ile mikron alt? tane WC ?ok yüksek a??nma direnci Yüksek kesme h?z? Plastik kompozitler, PCB, seramik, ah?ap ve MDF'nin delinmesi ve frezelenmesi i?in |

MT20.8? | 15%Co ile mikron alt? tane WC Yüksek mukavemet ve tokluk Yüksek h?zl? delme Kat? karbür z?mbalarda kullan?m i?in |

Cut-to-Length (CTL) Tungsten Carbide Rod, Ground, Polished, Chamfer one end

We have one of the largest and most complete lines of ground CTL carbide rods for cutting tool blanks in stock. Meetyou Carbide proudly announces that we have achieved the best cost-effectiveness for this kind of rods for cutting tool blanks. Because we use a unique method of pressing technology combined with the supreme quality powder from Germany H.C.Starck.

h6

Polished.

Our standard tolerance for the diameter is h6 polished. We can also provide h5 polished or other tolerance as per your requirement.

uzunluk

Cut.

Both advanced wire cutting and diamond wheel cutting are applied to cut the carbide rod into the length you need.

One End

Chamfered

45 degree chamfered one end is provided for better looking and a smooth edge.

- Complete lines of ground cut to length carbide rod for cutting tool blanks

- Standard h6 ISO diameter tolerances in inch and metric lengths and diameters

- Special perform like male center, female center, ball nose, step reduction, and shaped points, etc are available according to your drawing

Standard Size ,Metric, Milimeter

|

Φ3.0 X 60 |

Φ8.0 X 50 |

Φ12.0 X 120 |

|

Φ4.0 X 40 |

Φ8.0 X 60 |

Φ13.0 X 100 |

|

Φ4.0 X 46 |

Φ8.0 X 63 |

Φ14.0 X 75 |

|

Φ4.0 X 50 |

Φ8.0 X 75 |

Φ14.0 X 80 |

|

Φ4.0 X 60 |

Φ8.0 X 90 |

Φ14.0 X 83 |

|

Φ4.0 X 75 |

Φ8.0 X 100 |

Φ14.0 X 100 |

|

Φ4.0 X 100 |

Φ10.0 X 50 |

Φ16.0 X 80 |

|

Φ5.0 X 50 |

Φ10.0 X 70 |

Φ16.0 X 90 |

|

Φ5.0 X 60 |

Φ10.0 X 72 |

Φ20.0 X 100 |

|

Φ5.0 X 100 |

Φ10.0 X 75 |

|

|

Φ6.0 X 40 |

Φ10.0 X 80 |

|

|

Φ6.0 X 50 |

Φ10.0 X 90 |

|

|

Φ6.0 X 58 |

Φ10.0 X 100 |

|

|

Φ6.0 X 60 |

Φ12.0 X 70 |

|

|

Φ6.0 X 67 |

Φ12.0 X 79 |

|

|

Φ6.0 X 75 |

Φ12.0 X 83 |

|

|

Φ6.0 X 100 |

Φ12.0 X 100 |

OEM Mü?teri servisi

Gereksinimlerinize g?re notlar geli?tirebilir ve ?iziminizle ayn? ?ekli yapabiliriz. Lazer markalama ve n?tr paketi de avantajlar?n?z i?in mevcuttur.

s?n?f

| s?n?f | ? | MT09U | MT10S | MT12S | MT25S | MT06U | MT20.8 |

| ISO aral??? | ? | K10-K20 | K20-K40 | K20-K40 | K20-K40 | K05-K10 | K40-K50 |

| WC + di?er karbür | % | 91 | 90 | 88 | 88 | 93.5 | 85 |

| e? | % | 9 | 10 | 12 | 12 | 6.5 | 15 |

| WC tane büyüklü?ü | um | 0.4 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| yo?unluk | g / ㎝3 | 14.5 | 14.42 | 14.12 | 14.1 | 14.85 | 13.95 |

| sertlik | HV30 | 1890 | 1600 | 1580 | 1750 | 1890 | 1350 |

| ?HD | ? | 93.5 | 91.5 | 91.2 | 92.5 | 93.5 | 89.5 |

| enine kopma mukavemeti | N / mm | 3800 | 4100 | 4200 | 4400 | 3700 | 3800 |

| kpsi | ? | 590 | 609 | 638 | 540 | 551 | 551 |

| k?r?lma toklu?u | Mpa.m? | 10.2 | 14.2 | 14.7 | 13.5 | 10.1 | 17.5 |

| gencin modülü | kpsi | 86780 | 85360 | 80860 | 80000 | 91000 | 79086 |

| bas?n? dayan?m? | kpsi | 1145 | 1015 | 1010 | 1109 | 1156 | 957 |

s?n?f | ?zellikleri ve uygulamalar? |

MT09U? | 9%Co ile ultra ince taneli WC ?ok yüksek a??nma direnci ve mükemmel deformasyon direnci Yüksek kesme h?z? frezeleme, finisaj Sertle?tirilmi? ?elik, plastik, elyaf takviyeli malzemeler, HRC55-65 üzerinde kullan?m i?in |

MT10S? | 10%Co ile ultra ince taneli WC ?ok yüksek a??nma direnci ve mükemmel deformasyon direnci Yüksek kesme h?z? frezeleme ve delme Genel kullan?m i?in ve a?a??daki her türlü malzeme i?in uygundur |

MT12S? | 12%Co ile mikron alt? tane WC Yüksek tokluk ve a??nma direnci Paslanmaz ?eli?in i?lenmesi i?in ?zel olarak tasarlanm??t?r Paslanmaz ?elik, nikel bazl? ala??mlar, titanyum ala??m? ve ?zel ala??mlarda kullan?m i?in |

MT25S? | 12%Co ile ultra ince taneli WC ?ok yüksek tokluk ve yüksek a??nma direnci Yüzey i?lemleri, nikel ve nikel ala??mlar? i?in 45 ila 55HRC ?elikleri aras?nda sertli?e sahip ?eliklerin i?lenmesi ve kaba i?lemesi i?in uygundur |

MT06U? | 6% Co ile mikron alt? tane WC ?ok yüksek a??nma direnci Yüksek kesme h?z? Plastik kompozitler, PCB, seramik, ah?ap ve MDF'nin delinmesi ve frezelenmesi i?in |

MT20.8? | 15%Co ile mikron alt? tane WC Yüksek mukavemet ve tokluk Yüksek h?zl? delme Kat? karbür z?mbalarda kullan?m i?in |