Milling cutters are designed to leave grooves of corresponding specifications on the processed workpiece. It is a milling cutter with specific shape and structure. It can cut stainless steel, iron pipe, copper pipe, aluminum pipe, non-metallic pipe, plate and other materials under high-speed rotation.

end milling cutter

The end milling cutter is used to process grooves and step surfaces. The cutter teeth are on the circumference and end face. Generally, it cannot feed along the axial direction, but when there are end teeth passing through the center on the end milling cutter, it can feed axially. The cutting edge has two edges, three edges and four edges, with a diameter of φ 2~ φ 15mm, widely used in cut in milling, high-precision groove machining, etc.

Selection method of end milling cutter

When selecting end milling cutter, the workpiece material and processing position should be mainly considered. Straight tooth or left-hand end milling cutter shall be used when machining materials with long strip and strong toughness. In order to reduce the cutting resistance, machining can be carried out along the length direction of the tooth. When cutting aluminum and castings, the milling cutter with small number of teeth and large rotation angle can reduce the cutting heat. During groove machining, the appropriate tooth groove should be selected according to the discharge of chips, otherwise chip blockage will often damage the tool.

When selecting end milling cutter, we should pay attention to the following three aspects: first, select the cutter according to the condition that there is no chip blockage; Then, honing the cutting edge to prevent edge collapse; Finally, select the appropriate tooth slot.

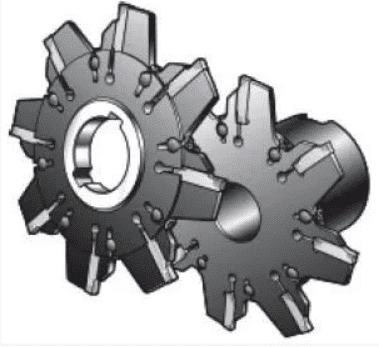

Three side edge milling cutter

Three side edge milling cutter is used to process all kinds of grooves and step surfaces. There are cutter teeth on both sides and circumference. The three side edge milling cutter used in cutting rectangular corners or grooves can be divided into staggered tooth shape with staggered cutting edges and parallel tooth shape with parallel cutting edges. Parallel tooth three face edge milling cutter is the most commonly used, while staggered tooth three face edge milling cutter is used for groove processing of steel. A large number of indexable cutters are often used in mass production, including semi three face edge milling cutter and full three face edge milling cutter. All three side edge milling cutter is mostly used for groove processing.

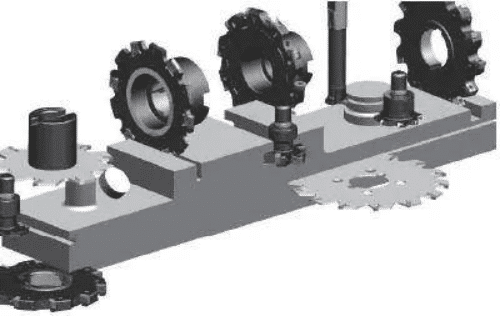

Selection basis of three face edge milling cutter

1. The number of cutting edges participating in cutting at the same time when selecting a three-sided edge milling cutter, it is necessary to select the processing material, tool radius and feed rate. For the cutting tool with small diameter, the change of cutting force borne by the cutting edge is easy to cause the bending of the tool body, so we must pay attention to the stability of load change.

2. Whether there is keyway or not. Keyway is not used in general processing. However, in the case of large feed and back draft or high-speed cutting, it is not enough to transfer the driving force only by the friction between the tool body and the tool handle. At this time, keyway should often be set. When the outer diameter is greater than 100mm, it is better to set the keyway.

3. Flatness of the side surface} it is difficult to improve the surface accuracy of the side surface of the groove if a three face edge milling cutter with a large outer diameter (relative to the inner diameter and cutting edge amplitude) is used to process the groove. Especially because a large number of chips will be mixed in the groove, even if the cutting speed is increased and the feed rate is reduced, the expected effect will not be achieved. The solution to this problem is to adjust the side flatness error between 0.005 ~ 0.01mm when installing the three face edge milling cutter on the mandrel, and then chamfer the sharp corner of the cutting edge into an R-shaped surface. There is also the use of large knife slots.

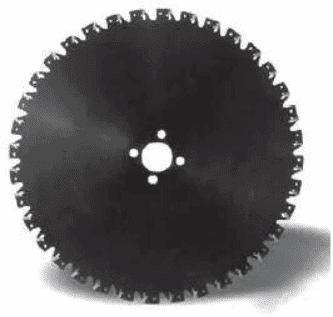

Saw blade milling cutter

Saw blade milling cutter is used to process deep grooves and cut off workpieces. There are many cutter teeth on its circumference. In order to reduce the friction during milling, there is a secondary deflection angle of 15 ′ ~ 1 ° on both sides of the cutter teeth. Features of saw blade milling cutter: the grinding machine can be used to regrind the edge teeth for many times. The service life of the grinded saw blade milling cutter is the same as that of the new saw blade milling cutter.

Application of saw blade milling cutter

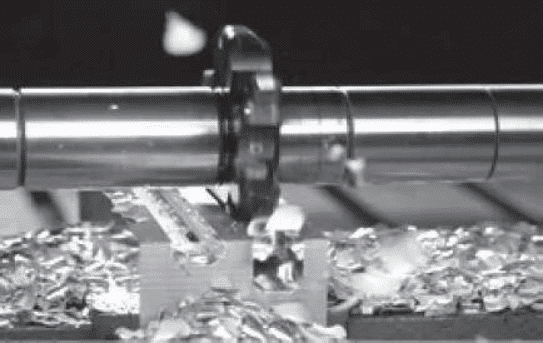

When using the saw blade milling cutter to mill the groove, because the diameter of the saw blade milling cutter is much larger than its thickness, it is easy to be affected by heating and often breaks down. There are many reasons for heating, especially the cutting heat and the heating caused by the contact between the machining surface and the tool due to side deformation in cutting.

In order to reduce faults in the machining process, it is necessary to use cutting fluid and devices that can absorb chips in order to collect chips. In addition, both sides of the saw blade milling cutter shall be ground into an inward concave shape. If the cutting edge is not hard, the heat will be more severe, so that the metal saw will bend or even break. Therefore, always pay attention to whether the cutting edge is hard. As for the correct use of metal saw, the use of cutting fluid and downward machining posture are the main principles. The freedom of cutting speed selection is relatively large, but the feed rate is limited by the rigidity of the cutting edge. Pay attention to this, and then select various processing conditions.

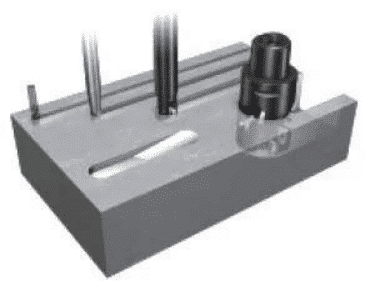

T-groove milling cutter

- groove milling cutter is used to mill T-groove. T-groove milling cutter can be divided into taper shank T-groove milling cutter and straight shank T-groove milling cutter. It can be used to process T-grooves on various mechanical tables or other structures. It is a special tool for processing T-grooves. It can mill T-grooves with required accuracy at one time. The end edge of the milling cutter has a suitable cutting angle, and the cutter teeth are designed according to oblique teeth and staggered teeth, with stable cutting and small cutting force.

Selection method of T shape groove milling cutter

In the slot milling process, the tool selection is determined according to the type and size of the slot. In the slot milling process, the three face edge milling cutter is generally preferred. When processing closed grooves and non-linear grooves, the advantages of end mills are highlighted. The following points shall be paid attention to in the selection of slot milling cutter:

(1) The tool type needs to be selected according to the length of the groove, closed or open, straight or non straight, deep or shallow, wide or narrow.

(2) The width and depth of the tool are usually determined by the tool.

(3) According to the available machine type and operation frequency, it is determined whether end milling cutter, long cutting edge cutter or three face milling cutter should be used.

- Three sided milling cutter provides the most effective machining method for milling long and deep grooves with large amount, especially when using horizontal milling machine.