Stamping dies work under the impact, vibration, friction, high pressure, tension, bending and torsion loads, and even at higher temperatures (such as cold extrusion). The working conditions are complex and easy to be worn, fatigued, fractured, deformed and other phenomena. Therefore, the requirement for the material of the working parts of the die is higher than that of the ordinary parts. Due to the different working conditions of various stamping dies, the requirements for the materials of working parts of the dies are also different.

Requirements for various stamping molds

1. for blanking dies

High wear resistance and hardness are required for working parts of sheet blanking dies, while high wear resistance and compressive yield point are required for thick sheet blanking dies. In order to prevent die fracture or blade collapse, high fracture resistance, high bending strength and toughness are also required.

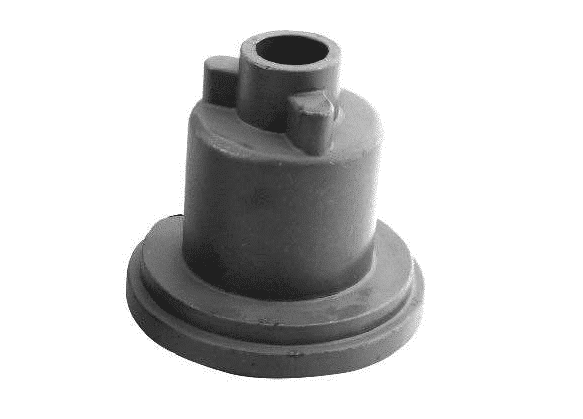

2. for Drawing Die Materials

It is required that the working parts of the die have good anti-adhesion (anti-occlusion), high wear resistance and hardness, a certain degree of strength and toughness, and good cutting performance, and the deformation during heat treatment should be small.

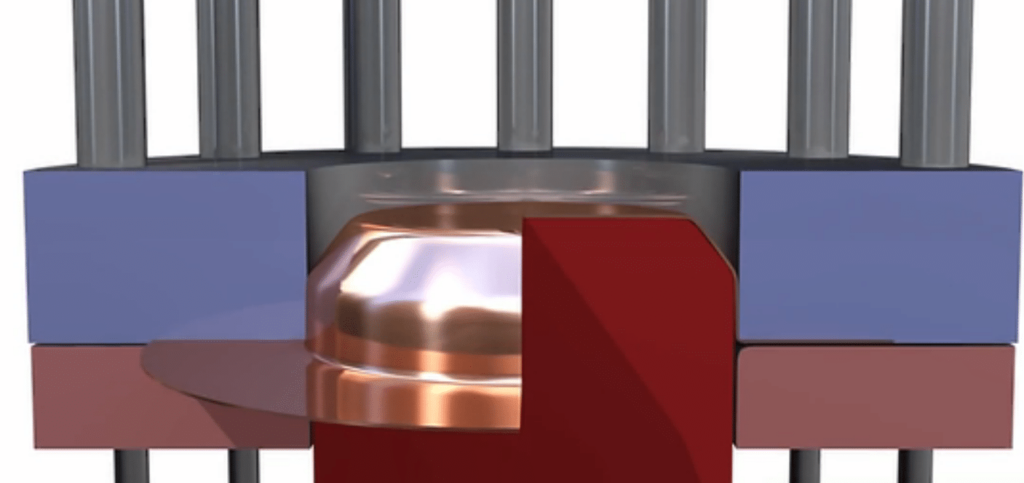

3. for cold extrusion dies

The working parts of the die are required to have high strength, hardness and wear resistance. In order to avoid impact fracture, certain toughness is also required. Because the extrusion will produce a greater temperature rise, so it should also have a certain degree of thermal fatigue resistance and thermal hardness.

Types and Characteristics of Stamping Die Materials

The materials of stamping die are steel, cemented carbide, steel-bonded cemented carbide, zinc-based alloy, low melting point alloy, aluminum bronze, macromolecule material and so on. At present, steel is the main material for stamping die manufacturing. The common types of die working parts are carbon tool steel, low alloy tool steel, high carbon high chromium or medium chromium tool steel, medium carbon alloy steel, high strength steel, matrix steel, cemented carbide, steel-bonded carbide and so on.

1.Carbon tool steel

T8A and T10A are the most widely used carbon tool steels in dies, which have the advantages of good processing performance and low price. However, the hardenability and red hardness are poor, the heat treatment deformation is large, and the bearing capacity is low.

T10A is a carbon tool steel with certain strength and toughness. However, the wear resistance is not high, the quenching is easy to deform and crack, and the hardenability is poor. It is only suitable for blanking dies with simple shape, small size and small number of workpieces.

2.Low Alloy Tool Steel

Low alloy tool steel is based on carbon tool steel with appropriate alloying elements. Compared with carbon tool steel, it reduces the tendency of quenching deformation and cracking, improves the hardenability and wears resistance of steel. The low alloy steels used for making dies are CrWMn, 9Mn2V, 7CrSiMnMoV (code CH-1), 6CrNiSiMnMoV (code GD), etc.

High carbon and low alloy steels are characterized by simple quenching operation, better hardenability than carbon tool steels, and easy deformation control. However, the wear resistance and toughness are still low, which can be used in medium batch blanking dies with complex workpiece shape.

3. High Carbon and Chromium Tool Steel

Commonly used high carbon and high chromium tool steels are Cr12 and Cr12MoV, Cr12Mo1V1 (code D2). They have good hardenability, hardenability and wear resistance. Heat treatment deformation is very small. They are high wear-resistant and micro-deformation die steels, and their bearing capacity is second only to high-strength steel. It can be used in mass production of dies, such as silicon steel sheet blanking dies. However, there is carbide inhomogeneity in this kind of steel, which is prone to carbide segregation and cutting edge collapse or fracture. Repeated upsetting (axial upsetting and radial upsetting) forging must be carried out to reduce the heterogeneity of carbides and improve service performance.

4.High strength steel

The common moulds are W18Cr4V (code 8-4-1) and W6Mo5 Cr4V2 (code 6-5-4-2, American brand M2) with less tungsten content, as well as 6W6Mo5 Cr4V (code 6W6 or low carbon M2) for carbon reduction and vanadium reduction high speed steel developed for improving toughness. High-speed steel has the highest hardness, wear resistance and compressive strength in die steel, and has high load-bearing capacity. But its toughness is low, and it may break or break when it is working, and the price is more expensive. High speed steel also needs to be forged to improve its carbide distribution. It is suggested that low temperature quenching and rapid heating quenching should be adopted to improve its toughness.

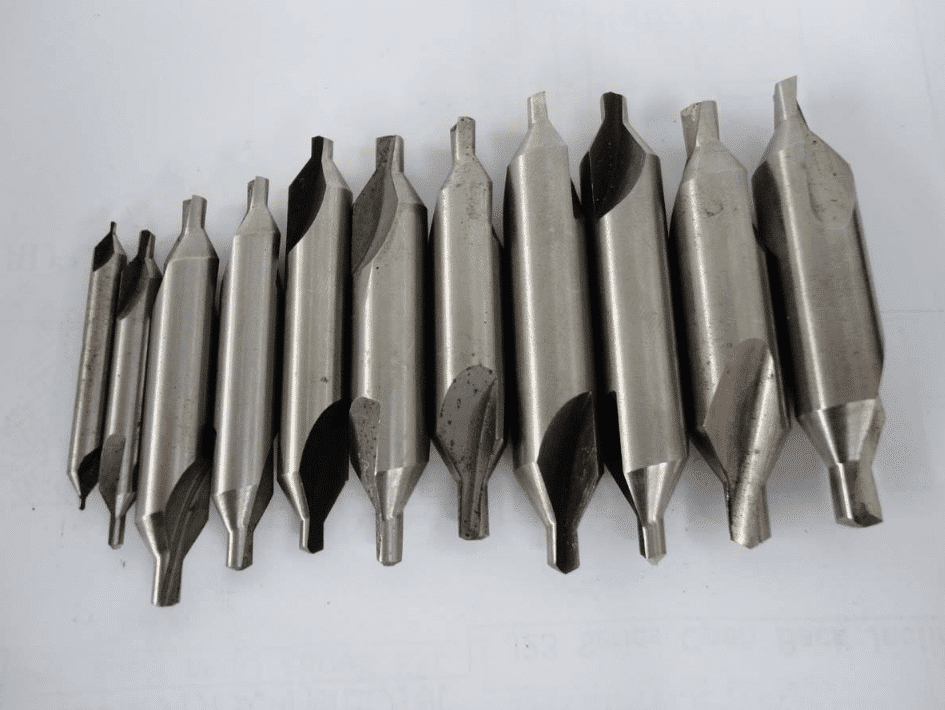

5. Cemented carbides and Steel-bonded Cemented Carbides

The hardness and wear resistance of cemented carbide are higher than that of any other kind of die steel, but its bending strength and toughness are poor. The cemented carbides used as dies are tungsten and cobalt, which have low impact and high wear resistance. The cemented carbides with low cobalt content can be selected. Cemented carbide with high cobalt content can be selected for dies with high impact. When the batch of workpiece is large, the hardness and wear resistance of cemented carbide or steel-bonded cemented carbide with higher hardness and wear resistance can be considered. The cemented carbide used as die material is tungsten cobalt. With the increase of cobalt content, the toughness and flexural strength increase, while the hardness decreases. YG10X with low cobalt content can be selected for the die with low impact force, YG15 or YG20 with high cobalt content can be selected for the die with medium or large impact force. The disadvantage of cemented carbide is poor toughness and difficult to process.

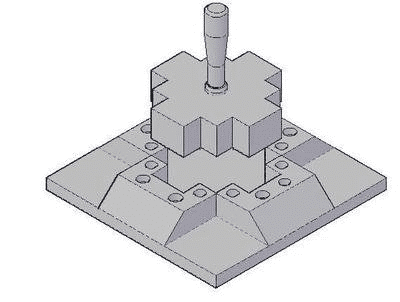

As a working part of the die, it can be designed as a mosaic structure. The properties of steel-bonded cemented carbide are between those of cemented carbide and high-speed steel. It can be machined and heat treated. After quenching and tempering, the hardness of steel-bonded cemented carbide can reach 68-73 HRC. It can be used to make complex and long-life dies. Steel bonded cemented carbides used as blanking dies include DT, GT35, TLMW50, GW50, etc.

Steel-bonded cemented carbide is sintered by powder metallurgy with iron powder as binder and titanium carbide or tungsten carbide as hard phase by adding a small amount of alloy element powder (such as chromium, molybdenum, tungsten, vanadium, etc.). The matrix of steel-bonded cemented carbide is steel, which overcomes the shortcomings of poor toughness and difficult processing of cemented carbide. It can be cut, welded, forged and heat treated. Steel-bonded cemented carbides contain a large number of carbides. Although their hardness and wear resistance are lower than those of cemented carbides, they are still higher than those of other steels.

Selection of Material for Stamping Die

Choosing blanking die material should consider the batch production of the workpiece, if the batch is not large, it is not necessary to choose the high-life die material; the material of the punched workpiece should also be considered, and the suitable die materials for different materials are also different. For blanking dies, wear resistance is an important factor to determine the life of dies. The wear resistance of steel depends on the condition of hard particles such as carbides and the hardness of matrix. The higher the hardness of both,

The more carbides, the better wear resistance. The wear resistance of common stamping die steel is carbon tool steel – alloy tool steel – matrix steel – high carbon high chromium steel – high speed steel – steel bonded carbide – cemented carbide.

In addition, the influence of the thickness, shape, size, and accuracy of the workpiece on the selection of die materials must also be considered.