Aluminum alloy is a general term for alloys with aluminum as the base. The main alloying elements include Cu, Si, Mg, and Sn, while secondary elements may include nickel, titanium, chromium, lithium, and others. Aluminum alloys have low density, good plasticity for shaping and processing into various forms. They exhibit excellent electrical conductivity, thermal conductivity, and corrosion resistance. Alloys formed by adding specific elements not only maintain the lightweight properties of pure aluminum but also possess higher strength.

Classification of aluminum alloy

Aluminum alloys can be classified into deformed aluminum alloys and cast aluminum alloys based on their processing methods.

Deformed Aluminum Alloys: Deformed aluminum alloys can be further categorized into non-heat-treatable and heat-treatable alloys, both of which exhibit moderate strength and hardness. The challenge in machining lies in their high plasticity, resulting in the formation of built-up edge during cutting, making it difficult to achieve a satisfactory performance. Mechanical properties can be improved through heat treatment, but strengthening is mainly achieved through cold working deformation. This category includes high-purity aluminum, industrial high-purity aluminum, industrial pure aluminum, and corrosion-resistant aluminum.

Cast Aluminum Alloys: Cast aluminum alloys have low ductility, with elongation typically below 4%, making them unsuitable for pressure processing and mostly suitable for cutting operations. Silicon-aluminum alloys demonstrate good casting properties and excellent mechanical performance, making them the most widely used cast aluminum alloys. The machinability of silicon-aluminum alloys is influenced by the silicon content, with higher content leading to more severe tool wear and poorer machining performance. Mechanical properties of cast aluminum alloys can be enhanced through heat treatment methods such as quenching and aging. This category includes hard aluminum, forged aluminum, superhard aluminum, and special aluminum alloys.

Processing defects of aluminum alloy material

Insufficient Rigidity

Due to the strong toughness and resistance to bending of aluminum alloys, it also implies that aluminum alloys lack rigidity. In the machining of thin-walled aluminum alloy components, excessive machining pressure can lead to component deformation. During the cutting process, issues such as stretching, breaking, and surface squeezing may occur, causing displacement and resulting in irreversible situations for thin-walled aluminum alloy components.

Susceptible to Thermal Deformation

Compared to steel, the coefficient of expansion for aluminum alloys is typically 2.4 times that of steel. Therefore, significant heat energy is generated during the machining process, leading to thermal deformation issues in aluminum alloys.

Insufficient Hardness of Aluminum Alloy

During mechanical machining, scratching issues often arise, leading to a lack of glossiness on the surface of thin-walled aluminum alloy components, which does not meet machining standards. Besides daily operational issues, this problem is mainly attributed to the insufficient hardness of aluminum alloy materials.

Thin Surface

The most prominent feature of thin-walled aluminum alloy components is their extremely thin surface. If CNC machine operators use numerical control machine tools for operations, the inherent elasticity of thin plates, coupled with the interaction of forces during cutting, can cause vibration issues on the cutting surface. This, in turn, makes it challenging to effectively control the thickness and dimensions of the cutting surface, thereby increasing the surface roughness of thin-walled aluminum alloy components.

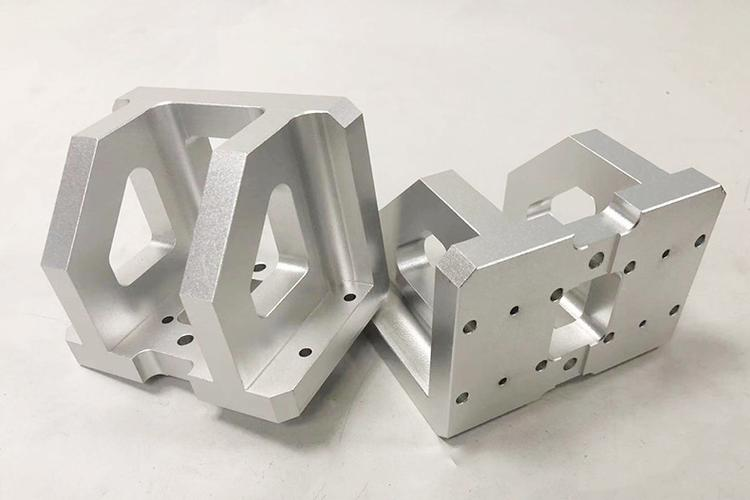

Processing methods?of aluminum alloy

Hot Working

Hot working refers to the plastic forming process completed above the recrystallization temperature when feeding aluminum alloy ingots. During hot working, the ingot’s plasticity is high, and the deformation resistance is low, allowing the production of larger products with smaller equipment capabilities.

Cold Working

Cold working refers to the plastic forming process completed below the temperature that induces recovery and recrystallization. The essence of cold working is a combination of cold working and intermediate annealing processes. Cold working can produce final products with smooth surfaces, precise dimensions, good structural properties, and the ability to meet various performance requirements.

Warm Working

Warm working is a plastic forming process that falls between cold and hot working. The primary purpose of warm working is to reduce the deformation resistance of the metal and enhance its plasticity.

Selection method of cutting aluminum alloy cutting tool

Due to the extremely sharp cutting edges and grooves of solid carbide tools, they exert low cutting forces in precision machining of aluminum alloys. They offer advantages such as large chip space and smooth chip evacuation. Consequently, solid carbide tools have gradually replaced traditional high-speed steel tools.

Aluminum alloy is easily machinable, allowing for higher cutting speeds suitable for high-speed machining. However, due to the low melting point of aluminum alloy, its plasticity increases with temperature. Under high-temperature and high-pressure conditions, significant frictional forces occur at the cutting interface, making it prone to tool adhesion. This is especially true for annealed aluminum alloys, which make it challenging to achieve a small surface roughness.

To obtain a smooth workpiece surface, a combination of rough and finish cutting is often employed. This is because various qualified workpiece blanks tend to have some oxide layers, causing considerable wear on the cutting tools. If the final cutting operation uses polished sharp tools for fine cutting, the above requirements can be met.

When selecting suitable tool materials for aluminum-silicon alloys, the silicon content guides the choice. For silicon content below 12%, tungsten steel tools in the ISO K10-K20 range can be used. If the silicon content exceeds 12%, diamond tools are preferred. Alumina ceramic tools are not suitable for aluminum alloy processing. During cutting, the oxidized aluminum chips can chemically bond with the ceramic tool, causing adhesion and chip lumps, leading to increased friction resistance and accelerated wear. Once chip lumps form, they replace the cutting edge during machining. In ultra-precision machining, the sharpness of the tool edge loses its significance. Additionally, the bottom of the chip lump is relatively stable, while the top is unstable and prone to breakage. After breaking, part of it is expelled with the chips, while the remaining part stays on the machined surface, making it rough. The protruding part of the chip lump beyond the tool edge also directly contributes to roughening the machined surface, and the friction between the chip lump and the already machined surface further increases surface roughness.