Um carro geralmente tem cerca de 30 tipos de 50 conjuntos de rolamentos instalados em diferentes pe?as rotativas. Na prática, os rolamentos de automóveis s?o geralmente classificados de acordo com as pe?as de instala??o ou uso. Correspondendo à divis?o do automóvel em motor, sistema de transmiss?o, sistema de dire??o e sistema de ar condicionado, os rolamentos do automóvel podem ser divididos em rolamento do motor, rolamento do sistema de transmiss?o, rolamento do sistema de dire??o e rolamento do ar condicionado de acordo com a posi??o de instala??o, e ent?o podem ser ainda mais subdividido em cada componente do sistema acima e na posi??o específica de instala??o do rolamento. Devido à diversifica??o do design de automóveis e rolamentos, diferentes pe?as e estruturas de rolamento s?o frequentemente usadas nas mesmas pe?as de automóveis diferentes. Usando o bitmap da pe?a de instala??o do rolamento e a tabela de espectro de tipo de rolamento correspondente, a posi??o de instala??o do rolamento pode ser mostrada de forma mais detalhada e intuitiva, e a rela??o interna entre componentes e rolamentos pode ser revelada fornecendo o modelo do rolamento, dimens?o externa e posi??o de instala??o ao mesmo tempo.

Hub bearing

1. The earliest hub bearing

The earliest used hub bearing is composed of two sets of single row radial ball bearings or tapered roller bearings. Its disadvantage is that the installation and maintenance need to fill grease and adjust the clearance. Improper grease type, dosage or not clean enough and improper clearance adjustment often lead to serious consequences of bearing life greatly reduced.

The improvement of hub bearing composed of two sets of single row bearings leads to the adoption of sealed double row bearing with pre adjusted clearance. The clearance of the bearing has been adjusted correctly during manufacturing, and the sealing and lubrication of the bearing itself can avoid the risk of dirt entering during installation and incorrect grease type and dosage. This kind of hub bearing which extends the functions of lubrication, sealing and clearance adjustment is called the first generation hub bearing.

Making the outer ring of the first generation hub bearing with flange constitutes the second generation hub bearing. The expansion of the structure and function of the hub bearing greatly simplifies the supporting structure of the hub, reduces the demand of the hub parts, and makes the installation easier. With the further expansion of the structure and function of the hub bearing, the third generation hub bearing has the functions of the bearing itself, the short shaft and the ordinary hub. Its inner ring flange is used to support the wheel and the brake disc, and the outer ring flange is used to support the brake disc Connect the suspension. In addition to many technical advantages, such as simplifying the design of automobile wheel and suspension device, reducing the volume, simplifying the assembly, easy to move and the possibility of installation error is very small, the cost of automobile parts is also effectively reduced.

At present, the expansion of structure and function has made the hub bearing develop to the fourth generation which is integrated with constant velocity universal joint, so that the technical performance and economic effect of hub bearing have reached a new level.

The main function of hub bearing is to bear load and provide accurate guidance for the rotation of hub. It bears both axial load and radial load, so it is a very important part.

The traditional bearings for automobile wheels are composed of two sets of tapered roller bearings or ball bearings. The installation, oiling, sealing and clearance adjustment of bearings are carried out on the automobile production line. This kind of structure makes it difficult to assemble, high cost and poor reliability in the automobile factory, and when the automobile is in the maintenance point, it also needs to clean, oil and adjust the bearing. Hub bearing unit is developed on the basis of standard angular contact ball bearing and tapered roller bearing. It integrates two sets of bearings. It has the advantages of good assembly performance, omitting clearance adjustment, light weight, compact structure, large load capacity, pre loading grease for sealed bearing, omitting external hub seal and avoiding maintenance. It has been widely used in cars There is also a trend to gradually expand the application of heavy trucks.

2. Installation and application of automobile hub bearing

In the past, single row tapered roller or ball bearings were mostly used in pairs. With the development of technology, car hub unit has been widely used in cars. The application scope and quantity of hub bearing unit are increasing day by day, and now it has developed to the third generation: the first generation is composed of double row angular contact bearings. The second generation has a flange used to fix the bearing on the outer raceway, which can simply cover the bearing on the axle and fix it with nuts. Make the maintenance of the car easier. The third generation of hub bearing unit is the combination of bearing unit and anti lock brake system ABS. The hub unit is designed with inner flange and outer flange. The inner flange is fixed on the drive shaft with bolts, and the outer flange installs the whole bearing together. Worn or damaged hub bearing or hub unit will make your vehicle have inappropriate and high cost failure on the road, and even cause harm to your safety.

clutch release bearing

1. Clutch release bearing function

The clutch release bearing is installed between the clutch and the transmission. The release bearing seat is loosely sheathed on the tubular extension of the bearing cover of the first shaft of the transmission. Through the return spring, the shoulder of the release bearing is always against the release fork and retreats to the final position, maintaining a clearance of about 3 ~ 4mm with the end of the release lever (release finger).

Since the clutch pressure plate and release lever operate synchronously with the engine crankshaft, and the release fork can only move along the axial direction of the clutch output shaft, it is obviously not feasible to use the release fork to shift the release lever directly. Through the release bearing, the release lever can rotate and move along the axial direction of the clutch output shaft, so as to ensure the smooth engagement of the clutch, soft separation and reduce wear, Extend the service life of clutch and the whole transmission system.

2. Working condition of clutch release bearing

In the process of use, it is affected by axial load, impact load and radial centrifugal force when rotating at high speed. In addition, because the reaction force of fork thrust separation lever is not in the same line, it also forms torsional torque. The clutch release bearing has poor working conditions, intermittent high-speed rotation and high-speed friction, high temperature, poor lubrication conditions and no cooling conditions.

3. Tolerance of clutch release bearing unit

1) the single inner diameter deviation of bearing unit shall be in accordance with the provisions in table 3-2. 2) The deviation of single straight diameter of contact circle △ D1s is ± 0.5mm. 3) The single diameter deviation of connecting groove △ D2S is: upper limit: 0 mm, lower limit: – 0.30 mm. 4) The actual fitting deviation △ HS with the sorting fork is: upper limit: 0 mm, lower limit: – 0.30 mm. 5) In the case of no axial load, the actual fit width deviation △ TOS of the bearing unit is ± 0.5 mm for the push bearing unit and ± 0.8 mm for the pull bearing unit.

Reasonable selection of universal bearing

The diversification of universal bearing design provides a wide space for the selection of automobile bearings. The key to improve the performance and life of automobile bearings is to select the most suitable bearing from many universal bearings in terms of structure, clearance, precision, size and performance.

1. Improvement of universal bearing

In order to adapt to the special environment and special requirements of automotive applications, the internal structure and materials of general bearings are improved, which improves the performance and service life of automotive bearings. These improvements include the improvement of bearing structural parameters, raceway and rolling element profile, cage structure and material, sealing structure and material and grease in order to improve bearing capacity, eliminate or reduce stress concentration, reduce volume, reduce friction and wear, and improve high-speed and high-temperature performance.

2. Structure and function expansion of universal bearing

Considering the bearing and its adjacent parts as a whole or a system, the optimization of the overall structure performance and service life is realized through the expansion of the general bearing structure and function. The automobile special bearing developed from this not only improves the performance and service life of the bearing itself, but also improves the performance and service life of the automobile parts or assemblies including the bearing. At the same time, it can simplify the automobile design, assembly, maintenance and reduce the cost of automobile parts. In the future, automobile bearings will continue to develop along the above main directions, so as to meet the development requirements of automobile design diversification and performance and life improvement

Automobile engine bearing

Automobile engine bearings generally refer to the bearings used in the automobile engine itself and its accessories, that is, the bearings used in the crank and connecting rod mechanism, valve train, fuel system, lubrication system, cooling system and ignition system. This section introduces the generator bearing, water pump bearing, ventilator bearing, drive belt tensioning wheel bearing and supercharger bearing which are widely used in the above mechanisms or systems

Generator bearing

1.Classification

There are two kinds of generators in automobile ignition system: Parallel DC generator and semiconductor rectifier generator.

Among them, alternator is developing rapidly because of its strong generating capacity, wide speed range, compact structure, reliable operation and long service life. For generator bearings, to adapt to this development means to improve the bearing capacity, limit speed, rotation accuracy, lubrication and sealing performance and noise performance

2.Design analysis

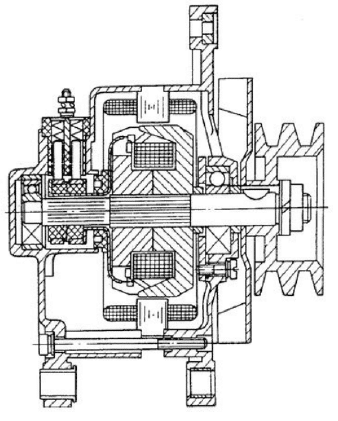

The use of generator bearing in semiconductor rectifier alternator is shown in the figure

Generator bearings are generally deep groove ball bearings and deep groove ball bearings with dust-proof or sealing structure. Sometimes double row ball bearings, cylindrical roller bearings or other structural types of bearings are used on the pulley side with greater stress. The selection of generator bearing should first consider the calculation life to meet the requirements, and then consider the limit speed, sealing, lubrication, noise and clearance.

a.Limit speed

The limit speed listed in the bearing sample is the limit speed under the standard conditions. When selecting the bearing, it should be corrected according to the actual service conditions. When the correction value is lower than the service speed, another bearing or high speed design should be selected.

b.Sealing

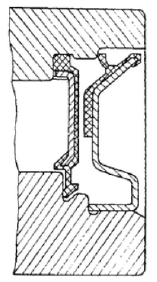

High speed and sealing are two contradictory characteristics of generator bearing seal design. The light contact high-speed rotary seal ring has good torque, temperature rise, dust-proof and grease sealing performance, but its anti muddy water performance is not good; and the contact seal ring with sealing performance will produce too high temperature rise. Therefore, the seal design of generator bearing must take into account the two contradictory characteristics of high speed and seal. In order to give consideration to the sealing performance and high speed, a good sealing design is to add an oil slinger outside the light contact seal ring, and form a labyrinth seal by the light contact seal ring and the oil slinger ring, so as to effectively prevent muddy water from entering the double sealing structure

The outer seal ring is composed of oil slinger ring and light contact seal lip, and forms labyrinth seal with outer ring and inner seal ring. At high speed and low speed, the labyrinth seal and light contact seal lip prevent muddy water from entering, so as to achieve excellent sealing performance in the whole speed range from low speed to high speed.

c.Lubrication

Generally, the selection of engine bearing grease is considered from the aspects of high speed, high temperature resistance, good low temperature starting performance and low noise.

The high speed adaptability of the grease can be determined by calculating the value of Ka DM n of the bearing.

Due to the need of low noise, the grease of generator bearing should not be too thick, so as to improve the damping effect of grease on rolling element vibration, and prevent the increase of noise and starting torque caused by dry friction at low temperature.

Based on the above reasons and the consideration of high temperature resistance and waterproof performance, composite calcium grease is generally used for the lubrication of generator bearing.

The filling amount of bearing grease can be determined according to the ratio between the limit speed of grease lubrication and the actual working speed.

ventilator bearing

In order to keep the engine at the best working temperature and reduce the power consumption as much as possible, modern engines generally use adjustable ventilators. When the driving air flow and radiation heat dissipation are enough to ensure that the optimal working temperature is not exceeded, the ventilators will stop. When the optimal working temperature is exceeded, the ventilators will enter the working state.

This intermittent ventilator has many kinds of transmission structures, and different structures of ventilators have different requirements for bearings. However, when directly installed in the ventilator impeller, the biggest problem faced by the bearing is to bear a large load and high temperature of 150-230 ℃.

Therefore, in the automotive ventilator, the lubrication and sealing of the bearing must be considered first, and then the proper fit between the outer ring of the bearing and the light metal shell should be ensured even at higher working temperature. In addition, the bearing should be able to bear the higher torque load caused by the imbalance of ventilators and guide accurately, and the friction torque should be reduced as much as possible in order to save energy and reduce noise.

Deep groove ball bearing

Deep groove ball bearing is the most common type of rolling bearing. This type of deep groove ball bearing is composed of an outer ring, an inner ring, a group of steel balls and a group of retaining frames. There are two types of deep groove ball bearings: single row and double row. The structure of deep groove ball can be divided into sealed and open type. Open type means that the bearing does not have a sealed structure. Sealed deep groove ball can be divided into dust-proof seal and oil-proof seal. The material of dust seal cover is steel plate stamping, which can simply prevent dust from entering bearing raceway. The oil proof type is the contact oil seal, which can effectively prevent the grease overflow in the bearing.

The type code of single row deep groove ball bearing is 6, and the code of double row deep groove ball bearing is 4. Its structure is simple, easy to use, is the most common production, the most widely used class of bearings.

Double bearing

For heavy ventilators, wide supporting seat and double row angular contact ball bearings or deep groove ball bearings installed in pairs are required. A supporting structure for car ventilator with two sets of deep groove ball bearings

Needle roller bearing

If there is enough space, two sets of deep groove ball bearings can be used to support the whole ventilator assembly, while a set of stamped outer ring needle roller bearings can be used to support the turbine and fan on the pump shaft. The ventilator assembly is supported by two sets of grease lubricated sealed deep groove ball bearings. Only one set of punched outer ring needle roller bearing directly installed in the ventilator is under high temperature. Therefore, the lubrication, sealing and matching of the needle roller bearing must be designed accordingly.

bearing with seat

Rolling bearing with seat is a kind of high-precision component product which is composed of grease sealed rolling bearing and bearing seat of various shapes. The rolling bearing with seat can be directly installed on the main body of the mechanical device through several bolts. It has automatic self-aligning performance and can supplement grease. It is a very simple product for installation and use.

The rolling bearing with seat is composed of a ball bearing with a spherical outer surface component and a bearing seat with a spherical inner hole