Cemented carbide is a kind of cemented carbide which is made by powder metallurgy process from the hard compound of refractory metal and bonding metal. Because of its good hardness and strength, it is widely used in many fields. With the requirement of high temperature performance and corrosion resistance of cemented carbide materials getting higher and higher, the performance of existing cemented carbide materials is difficult to meet its use requirements. In the past 30 years, many scholars have carried out experimental research on WC based compounds and obtained a series of research results.

WC metals

WC-Co

The cementitious material widely used in tungsten carbide is cobalt. WC Co system has been studied extensively. The addition of CO makes WC have good wettability and adhesion. In addition, as shown in Figure 13.2, the addition of CO can also significantly improve the strength and toughness.

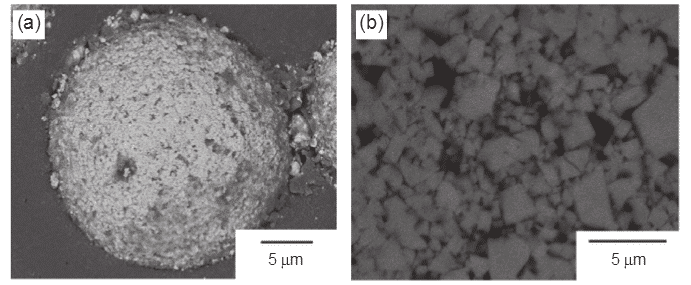

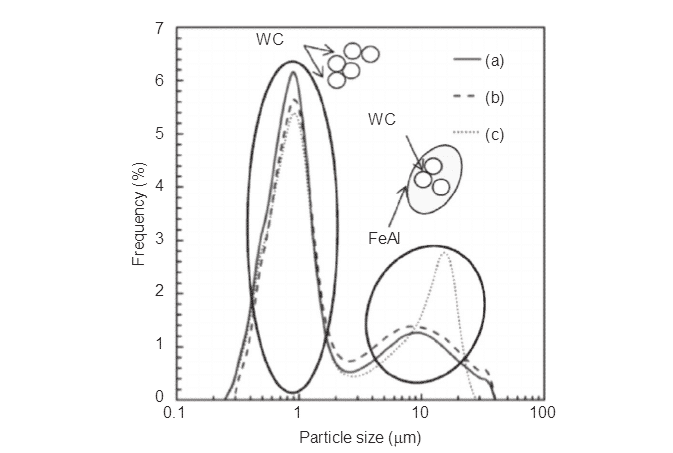

Figure 13.3 backscatter electron micrograph of WC Co powder showing the external and cross-sectional structures: (a), (b) F8; (c), (d) M8; and (E), (f) C8.

He performed backscatter electron imaging of F8, M8 and C8 powders and their polished sections. It was observed that all powders have typical spherical shape. F8 powder shows a dense accumulation of fine carbides, while M8 and C8 powder show a relatively loose accumulation structure with some pores. On the polished section, all samples show obvious scattering phenomenon, and the hardness and wear resistance are inversely proportional to the cobalt content. The Vickers hardness (HV) varies from 1500 to 2000 HV30, and the fracture toughness ranges from 7 to 15 MPa M1 / 2. This significant change is a function of carbide composition, microstructure and chemical purity.

Generally speaking, the smaller the particle size, the higher the hardness and the better the wear resistance. The higher the volume fraction of CO, the higher the fracture toughness, but the lower the hardness and wear resistance (Jia et al., 2007). Therefore, in order to obtain better performance, it is inevitable to consider using other cementitious materials instead.

On the other hand, because of the above reasons, it is not scientific in strategy and easy to affect the price trend. In addition, the combination of WC and co dust is worrisome because they are more lethal than any single use.

WC-Ni

Nickel is cheaper and easier to obtain than cobalt. It has a good toughening property. It can be used to improve corrosion / oxidation performance, high temperature strength and wear resistance in harsh environment. Compared with WC Co alloy, the plasticity of the material is lower. Because nickel dissolves well in WC, it is used as an adhesive for WC substrates, which results in a strong bond between them.

WC-Ag

The addition of Ag makes WC a kind of arc resistant material. Under the action of overload current, WC is often loaded in switching devices, which can be attributed to the well-known electrical contact resistance (RC) of the latter. It is worth mentioning that the resistivity of WC Ag composite decreases with the increase of Ag content, and the hardness decreases with the increase of Ag content, which is due to the great difference between the hardness of WC and Ag. In addition, the coarse WC grains have very low and stable contact resistance.

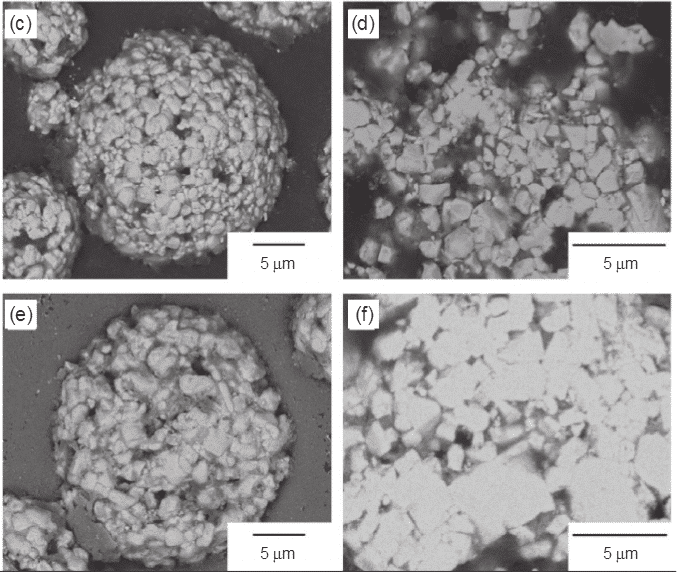

Figure 13.4 shows the average electrical contact resistance (RC) produced by the switch

Cycle 11e50 with different silver content and WC particle size, because RC of most materials is observed to be stable after 10 switching cycles. The contact resistance of silver is between 50-55 wt% (volume ratio 60% and 64.6%) in WC with a particle size of 4 mm, and between 55-60 wt% (volume ratio 64.6% and 69%) in WC with a particle size of 0.8 and 1.5 mm. Therefore, this determines the initial composition of the investment, where the Ag matrix is fully interconnected. For fixed components, a decrease in contact resistance between 1.5 and 4 mm WC particle size was observed, which also marks the permeation threshold.

WC-Re

Scientists are using tungsten carbide to strengthen rhenium in order to obtain better performance than WC Co, because RE can bring high temperature hardness and good combination

Figure 13.4 the ratio of the average electrical contact resistance at different Ag content and WC particle size to the contact resistance of the WC substrate during cycles 11 to 50 is co or Ni. According to the microstructure characteristics of WC coere (20% RE content), it is described that WC coere retained in CO and continued to form HCP structure, thus improving the hardness of the alloy. The researchers also strengthened re in WC Ni and found similar inferences. Due to its highest hardness and twice the durability of WC Co, the alloy is used to manufacture competitive tool parts. When cold pressing WC and Re powders followed by a patented hot pressing process, more than 2400 kg/mm~2 of HV was observed (compared to 1700 kg/mm~2 for WC-Co)

WC intermetallics

WC-FeAl

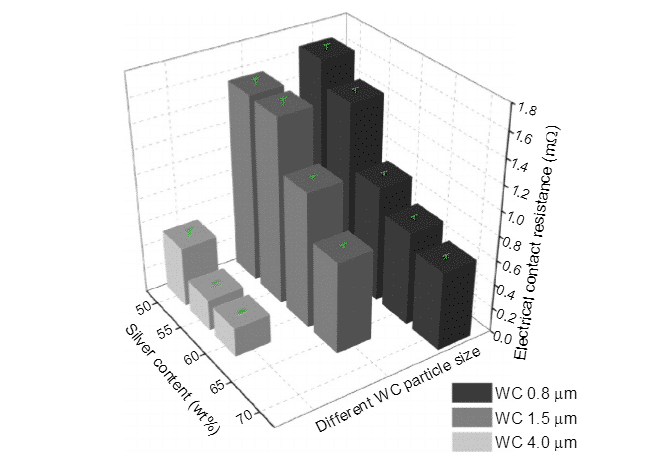

In the past few decades, intermetallic compounds as ceramic adhesives have attracted people’s attention. Iron aluminide has excellent oxidation resistance and corrosion resistance, low toxicity, high hardness, good wear resistance, high temperature stability and good wettability. It is thermodynamically suitable for WC as binder. The hardness and fracture toughness of WC FeAl and WC Co are basically the same. The hardness and wear resistance of WC Co alloy are similar to those of conventional WC Co alloy. It can be considered that if the grain size can be optimized, it is possible to replace the traditional WC Co. The particle size distribution curve of WC FeAl mixed powder prepared by different ball milling and / or drying processes is shown in Figure 13.5. The three curves in Figure 13.5 have bimodal distribution. In Figure 13.5, the left peak of the smaller particle size corresponds to the left peak of a single WC particle. The correct peak value of larger particle size corresponds to the peak value of FeAl fragments containing some WC particles. When the correct peak moves, the left peak does not depend on the grinding and / or drying process. The correct peak of D-R powder (dehydrated ethanol as solvent for rapid drying) shifts to the corresponding peak of the other two powders.

Figure 13.5 Particle size distributions of WC-FeAl mixed powders prepared from various powder processes.

WC-ceramics

WC-MgO

Wc-mgo composite materials have been widely used because of the addition of MgO particles in the WC matrix, which has little effect on the hardness and significantly improves the toughness of the materials. The hardness is inversely proportional to the toughness, but in the case of this alloy, the toughness is obtained when the hardness loss is very small. Adding a small amount of VC, Cr3C2 and other grain growth inhibitors to the studied material can not only control the grain growth in the sintering process, but also improve the mechanical properties of the material.

WC-Al2O3

It must be mentioned here that Al2O3 is used as a reinforcing material for WC, and vice versa, because of their excellent mechanical and physical properties.

Sintering temperature and holding time have significant effects on the microstructure and mechanical properties of wc-40vol% Al2O3 composite. With the increase of sintering temperature and holding time, the relative density and particle size increase. At the same time, the values of high pressure and fracture toughness increase first and then decrease. The microstructure of crack path reveals the existence of crack bridging and crack deflection. In wc-40vol% Al 2O 3 composites, the main toughening mechanism is the generation of secondary and lateral cracks. Another study shows that HV is about 20e25gpa and fracture toughness is 5e6mpa.m1/2.

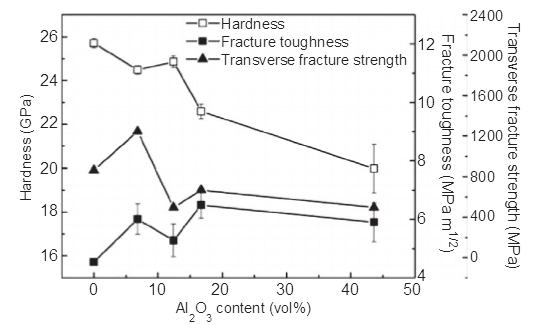

Figure 13.6 shows the variation trend of hardness, fracture toughness and transverse fracture strength with alumina content. It should be noted that these values are quite different from those reported (Mao et al., 2015). Pure WC has the highest hardness and the lowest fracture toughness. The addition of Al2O3 improves the fracture toughness, but the hardness of pure alumina is lower than that of pure WC, and the hardness of wc-al2o3 composite decreases. The different results in Figure 13.6 show that the mechanical properties depend not only on the alumina content, but also on the production process and grade of different substrates.

WC abrasives

WC cBN

Because CBN has excellent hardness, thermal stability and reaction activity with iron, adding CBN to WC Co can improve the wear resistance, hardness and mechanical properties of the material. Once CBN is strengthened into WC matrix, strong adhesion will be produced. In addition, better fracture toughness can be obtained by crack deflection or bridging of CBN particles. The two main obstacles in the process of CBN addition are the conversion from CBN to hBN and the strong covalent bonding between B and N, which results in the low sintering ability of CBN and cemented carbide.

WC diamonds

WC diamond has excellent fracture toughness, crack growth resistance and reflection resistance. This material can only be produced under thermodynamic conditions to prevent diamond from turning into graphite. Through more research to improve the performance of this material, we can make up the huge cost gap, which is very necessary.