The welding characteristics of austenitic stainless steel: the elastic and plastic stress and strain are very large in the welding process, but there are few cold cracks. There is no quenching hardening zone and grain coarsening in welded joint, so the tensile strength of weld is high.

The main problems of austenitic stainless steel welding are: large welding deformation; because of its grain boundary characteristics and sensitivity to some trace impurities (s, P), it is easy to produce hot cracks.

Five major welding problems and treatment measures of austenitic stainless steel

The formation of chromium carbide reduces the intergranular corrosion resistance of welded joints

Intergranular corrosion: according to the theory of poor chromium, when the weld and heat affected zone are heated to 450 ~ 850 ℃ sensitization temperature zone, chromium carbide precipitates on the grain boundary, resulting in poor chromium grain boundary, which is not enough to resist corrosion. Zero

(1) The following measures can be adopted to limit the intergranular corrosion of weld and the corrosion of sensitized temperature zone on the target material

a. In order to avoid the formation of Cr23C6, stabilizing elements such as Ti and Nb were added to the base metal to reduce the carbon content in the base metal and weld.

b. The dual phase structure of austenite and a small amount of ferrite is formed in the weld. When there is a certain amount of ferrite in the weld, the grain size can be refined, the grain area can be increased, and the amount of chromium carbide precipitation per unit area of grain boundary can be reduced.

Cr23C6 is preferentially formed in ferrite instead of poor chromium at austenite grain boundary; ferrite between austenite can prevent corrosion from diffusing into interior along grain boundary.

c. Control the residence time in the sensitization temperature range. Adjust the welding thermal cycle to shorten the residence time of 600-1000 ℃ as much as possible. The welding method with high energy density (such as plasma argon arc welding) can be selected. The welding line energy is smaller. Argon gas is applied to the back of the weld or copper pad is used to increase the cooling rate of the welded joint. The number of arc striking and arc stopping is reduced to avoid repeated heating. The contact surface between multi-layer welding and corrosive medium is as last as possible Welding, etc.

d. After welding, solid solution treatment or stabilization annealing (850-900 ℃) should be carried out after heat preservation and air cooling to fully precipitate carbide and accelerate chromium diffusion.

(2) For this reason, the following preventive measures can be taken:

Due to the strong diffusion ability of carbon, it will segregate in the grain boundary and form supersaturation state during cooling, while Ti and Nb will remain in the crystal due to the low diffusion ability. When the welded joint is reheated in the sensitized temperature range, the supersaturated carbon will precipitate in the form of Cr23C6.

a. Reduce carbon content. For stainless steel containing stabilizing elements, the carbon content should not exceed 0.06%.

b. Adopt reasonable welding process. In order to reduce the residence time of overheated zone at high temperature, a smaller welding line energy should be selected to avoid “medium temperature sensitization” effect in the welding process.

In case of double side welding, the weld contacting with corrosive medium should be welded last (this is the reason why internal welding of large diameter thick wall welded pipe is carried out after external welding). If it cannot be implemented, the welding specification and weld shape should be adjusted to avoid the overheated area contacting with corrosive medium from being sensitized again.

c. Post weld heat treatment. After welding, solid solution or stabilization treatment shall be carried out.

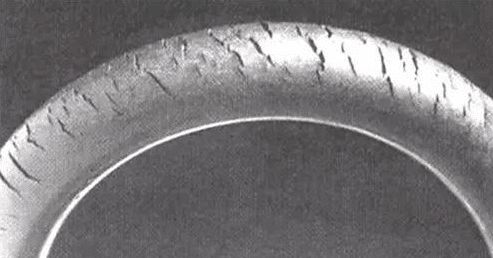

Stress corrosion cracking

The following measures can be taken to prevent the occurrence of stress corrosion cracking:

a. Correct selection of materials and reasonable adjustment of weld composition. High purity chromium nickel austenitic stainless steel, high silicon chromium nickel austenitic stainless steel, ferrite austenite stainless steel and high chromium ferrite stainless steel have good stress corrosion resistance. When the weld metal is austenitic ferrite dual phase steel, the stress corrosion resistance is good.

b. Eliminate or reduce the residual stress. The surface residual stress was reduced by polishing, shot peening and hammering.

c. Reasonable structural design. In order to avoid large stress concentration.

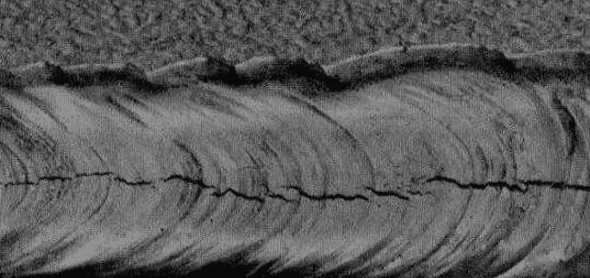

Welding hot crack (weld crystallization crack, HAZ liquefaction crack)

The hot crack sensitivity mainly depends on the chemical composition, microstructure and properties of the material. Ni is easy to form low melting point compounds or eutectic with impurities such as s and P. segregation of boron and silicon will promote hot cracking.

It is easy to form coarse columnar crystal structure with strong directivity, which is conducive to the segregation of harmful impurities and elements, thus promoting the formation of continuous intergranular liquid film and improving the sensitivity of hot cracking. If the welding is heated unevenly, it is easy to form large tensile stress and promote the generation of welding hot cracks.

Preventive measures:

a. The contents of harmful impurities s and P should be strictly controlled.

b. Adjust the structure of weld metal. The δ phase in the weld can refine the grain size, eliminate the directionality of single-phase austenite, reduce the segregation of harmful impurities in the grain boundary, and the δ phase can dissolve more s and P, reduce the interface energy and form the liquid film between grains.

c. Adjust the composition of weld metal alloy. The sensitivity to hot cracking can be reduced by adding Mn, C, N and trace elements such as cerium, pickaxe and tantalum in single phase austenitic steel.

d. Process measures. In order to prevent the formation of coarse columnar grains, the small heat input and small cross-section weld bead should be used.

For example, 25-20 austenitic steel is prone to liquefying cracks. By strictly limiting the impurity content and grain size of the base metal, adopting high energy density welding method, small line energy and increasing the cooling rate of the joint, etc.

Embrittlement of welded joint

The plasticity of welded joint should be guaranteed for hot strength steel to prevent high temperature embrittlement; low temperature steel should have good low temperature toughness to prevent brittle fracture of welded joint at low temperature.

Welding deformation is large

Due to the low thermal conductivity and large expansion coefficient, the welding deformation is large, so the fixture can be used to prevent deformation. Selection of welding methods and welding materials for austenitic stainless steel: austenitic stainless steel can be welded by TIG, MIG, paw and saw.

The welding current of austenitic stainless steel is small because of its low melting point, small thermal conductivity and high resistance coefficient. Narrow weld and narrow pass should be used to reduce high temperature residence time, prevent carbide precipitation, reduce weld shrinkage stress and reduce hot crack sensitivity.

The composition of welding material, especially Cr and Ni, is higher than that of base metal. The welding material containing a small amount of ferrite (4-12%) is used to ensure good crack resistance (cold cracking, hot cracking and stress corrosion cracking) of the weld.

When ferrite phase is not allowed or impossible to exist in the weld, the welding material containing Mo, Mn and other alloy elements should be selected.

C, s, P, Si and Nb in welding materials should be as low as possible. NB may cause solidification cracks in pure austenite weld, but a small amount of ferrite in the weld can be effectively avoided.

Nb containing welding materials are usually used for welding structures which need to be stabilized or stress relieved after welding. When submerged arc welding is used to weld medium plate, the burning loss of Cr and Ni can be supplemented by the transition of alloy elements in flux and welding wire;

Due to the deep penetration, attention should be paid to prevent the formation of hot cracks in the central zone of the weld and the reduction of corrosion resistance in the heat affected zone. Attention should be paid to the selection of thinner welding wire and smaller welding line energy. The welding wire should be low in Si, s and P.

The ferrite content in weld of heat-resistant stainless steel should not be more than 5%. For austenitic stainless steel with more than 20% Cr and Ni, high Mn (6-8%) welding wire and alkaline or neutral flux should be selected to prevent Si addition to weld and improve its crack resistance.

The special flux for austenitic stainless steel increases little Si, which can transfer alloy to the weld and compensate the burning loss of alloy elements to meet the requirements of weld performance and chemical composition.