The characteristics of coarse-grain WC

Compared to regular carbides, coarse-grain carbides possess the following characteristics:

1High Hardness

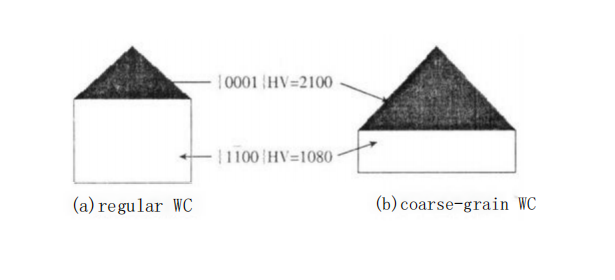

WC belongs to the hexagonal crystal system with anisotropic crystal structure. Its physical and mechanical properties vary based on the crystal plane orientation or Miller indices. Particularly, its hardness exhibits strong anisotropy. The Vickers hardness (HV) values for the basal {0001} plane and edge {1100} plane are HV2100 and HV1080, respectively (Figure 1). Due to the more than twofold difference in hardness between the {0001} and {1100} planes, in coarse-grain carbides where the proportion of WC grains with higher {0001} plane hardness is significant, the overall hardness increases. Consequently, carbides containing coarse-grain WC demonstrate elevated wear resistance.

Figure 1: Morphology model of WC grains.

2Good Toughness

In conventional carbides, fine microcracks propagate primarily along the weakest interfaces such as WC/WC grain boundaries or WC/Co interfaces. In coarse-grain carbides, these microcracks tend to propagate in a zigzag pattern around the coarse WC grains. The presence of coarse WC grains impedes the further propagation of these microcracks, enhancing the fracture toughness of the carbide.

3High-Temperature Hardness,Low High-Temperature Creep Deformation

At elevated temperatures of 1000 ℃, the high-temperature hardness of coarse-grain carbides surpasses that of regular carbides, demonstrating excellent hot hardness. For carbides with a certain cobalt content, coarse-grain WC carbides exhibit greater resistance to thermal deformation compared to standard carbides.

4Low Production Costs of coarse-grain WC

Anisotropic coarse-grain carbides can be produced using conventional sintering techniques, eliminating the need for additional methods like hot pressing. As a result, production costs are reduced.

Toughening mechanism of coarse-grain WC

The mechanism behind WC-toughened carbides primarily results from the enlargement of WC grain size, which enhances the diversion and branching of cracks, thereby increasing the toughness of WC-Co carbides.

1The percentage of WC grain self-fracture area increases with the enlargement of WC grain size, reaching levels above 30%. Relevant studies indicate that the crack resistance of high-carbon carbides is on average 0.6 to 4.9 units higher than that of low-carbon carbides. Additionally, during crack propagation, carbides partially enhance the fracture energy of WC-Co carbides: for low-Co carbides (Co < 10.0%), this increase ranges from 40% to 70%, whereas for carbides containing 15% Co, it decreases to 15% to 20%.

2If the WC grain size is within the range of 1.2 to 6 μm, plastic deformation and flow of WC grains can be observed. When WC grain size exceeds 6 μm, the grains tend to undergo brittle fracture, and the critical strength of WC grains becomes lower than their yield limit.

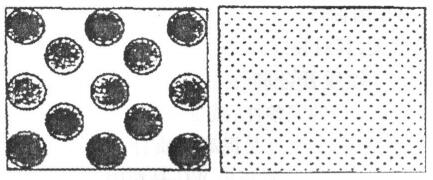

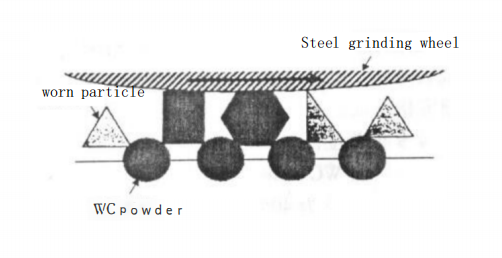

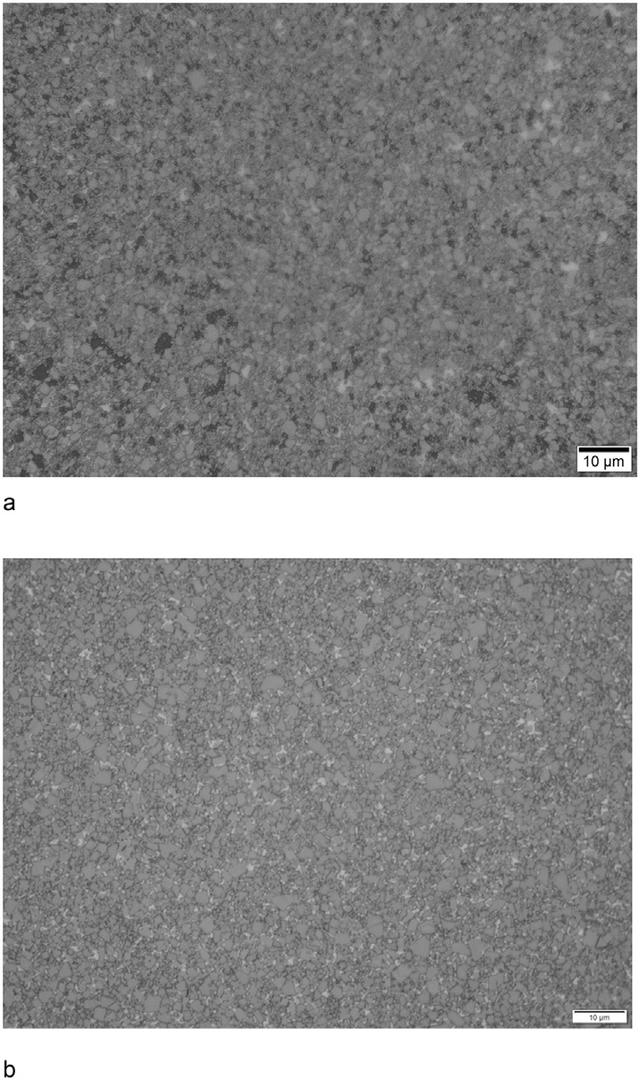

3With the same cobalt content, polycrystalline carbides have thicker cobalt phases, which should facilitate high-temperature creep deformation. Coarse-grain WC is employed in mining tools worldwide, and the grain size typically ranges from 3.0 to 4.5 μm. In some grades of mining carbides, the strength can even reach 3,500 N/mm2. Figure 2 illustrates the structure of a coarse-grain carbide, and Figure 3 demonstrates the grinding process of such an carbide.

Figure 2: Structure illustration of coarse-grain carbide

Figure 3: Illustration of grinding process for coarse-grain carbide

From the structural representation in Figure 2, it’s evident that the cobalt layer in coarse-grain carbides is considerably broad, facilitating plastic deformation of cobalt. This attribute contributes to the exceptional toughness typically observed in coarse-grain carbides. As depicted in Figure 3, the large grain size of coarse-grain carbides results in strong cobalt bonding with WC due to the sizeable cobalt phase relative to the WC grains. This robust bonding makes it difficult for WC grains to be pulled out, leading to excellent wear resistance.

The current research status of coarse-grain WC

Internationally, research on carbides for mining applications, much like the study of cutting tool materials, is highly regarded.

1Sweden’s Sandvik company initiated the manufacturing of cemented carbide inserts with WC in 1942. In 1945, the rock drilling bits produced by the company accounted for about 50% of European sales. The company’s research reports indicate that the crucial determinants of carbide performance are the particle size of WC and the mass fraction of cobalt. Wear resistance increases with decreasing WC particle size and cobalt mass fraction. Conversely, toughness improves with larger WC particle sizes and higher cobalt mass fractions, but it’s not feasible to simultaneously enhance both wear resistance and toughness.

2In 1995, the UK’s ZCC Group developed cemented carbide drill bits for rotary rock drilling using metal binders like Cu, Ni, Co, and Fe. The wear ratio was reduced by half compared to bits without Cu-Ni additives. They found that an average hard phase particle size between 2.5 to 3.5 μm yielded particularly favorable conditions. The cemented carbide body contained over 85% WC, with the content of other carbides (such as TiC or TaC) not exceeding 5%.

3Germany began experimental work on cemented carbide rock drill bits with WC before 1946. By around 1998, they developed coarse-grain carbide?drill bits like Gl, N68, G3, and G2, typically with an average grain size of 4 μm.

4An Italian drilling tool company manufactures drill bits using the following carbide?composition: 85% w (W), 10% w (Co), and 5% w (Fe). With their seal sliding bearing drill bits, in extremely hard formations and drilling speeds of 0.5 m/s, the drill bit lifespan reaches 80 to 150 hours.

4 Preparation methods of coarse-grain WC powder

Traditional methods for producing coarse-grain WC include:

1High-temperature carburization of coarse tungsten powder

This classic method is dominant domestically. It improves WC properties due to extended high-temperature carburization, minimizing lattice defects and microstrain while enhancing WC’s plasticity.

2Mid-temperature reduction and high-temperature carburization of lithium salt-doped tungsten oxide

Emerging in the mid-1980s, this method replaces certain traditional processes. Additives accelerate volatilization and deposition during WO3 reduction, allowing tungsten powder to grow at lower temperatures. Resulting WC is mainly used for mining carbides and cold die carbides.

3High-temperature carburization with cobalt or nickel additives

The addition of small amounts of cobalt, nickel, or their oxides during tungsten powder carbonization alters the carburization mechanism and enhances the process’s speed. The influence of grain size and cobalt content on coarse-grain WC’s production is significant; greater cobalt content yields coarser WC.

4Sodium salt addition method

Sodium salt is added to Ammonium Paratungstate (APT), followed by reduction at high temperatures, producing coarse tungsten powder with grain sizes above 10 μm. Subsequent high-temperature carburization yields coarse WC. This method is employed by the UK’s John Brown Company.

5APT rapid sintering and rapid reduction method

APT is rapidly sintered at 850-1000 ℃ in an oxidative atmosphere, then rapidly reduced at 1100-1300 ℃ in a hydrogen furnace. This produces tungsten powder with a particle size of 25-36 μm.

6Halide boiling layer hydrogen reduction method

Tungsten chloride or fluoride is reduced with H2 in a boiling layer. H2 and raw tungsten powder are fed into the reactor bottom, forming a boiling tungsten layer. Halide vapor is introduced at the reactor’s top, reduced to tungsten powder by H2 at an optimal temperature, and deposited on the original tungsten powder. The process gradually increases the grain size of the original tungsten powder, producing coarse tungsten powder over 40 μm. The United States’ Union Carbide Corporation employs this method to produce coarse tungsten powder in WF6 for rock drilling tool cemented carbides.

7Coarse-grain aluminum thermal process

This patented method produces high-purity, coarse-grain, large-block, single-phase WC crystals directly from tungsten concentrates through highly endothermic reactions. The resulting micron-sized WC is used in various cemented carbides, successfully applied to manufacturing tools for hard rock mining, coal mining, road construction, molds, wear-resistant components, and indexable inserts.

8Tungsten concentrate molten salt carburization (gas injection method)

Developed by the US Bureau of Mines, similar to the aluminum thermal method. Tungsten concentrates are decomposed using Na2SiO3-NaCl melt at 1050-1100 ℃. The generated Na2WO4-NaCl melt separates from the silicate phase containing Fe, Mn, and Ca. Methane is then injected into the melt, producing coarse WC. Cemented carbides (w (Co) 8.25%-10%) produced from this WC by the US Bureau of Mines and Canada’s International Carbide Company have properties similar to those produced by conventional processes.

5 Wniosek

With the advancement of technology, the application scope of coarse-grain WC is expanding rapidly, and the demand is growing exponentially, indicating promising market prospects. Currently, research and development of high-quality coarse-grain WC and even large-grain single-crystal WC have become hot topics worldwide. For coarse-grain WC, the research focus has shifted from studying the kinetics of reduction and carburization processes, behavior of trace elements, powder morphology, and particle size to the development of new processing methods and application areas.

These research and development efforts have not only significantly improved the properties of WC but have also led to notable enhancements in the quality and performance of carbide?products.