Generally speaking, improving the wear resistance of carbide?leads to a decrease in carbide?toughness, and increasing the toughness of carbides results in decreased wear resistance. Wear resistance and toughness are a contradictory unity. How to resolve this contradiction has become a major challenge in today’s carbide?production. Through test, we have found that adding trace rare earth elements to mining?carbide?can effectively address this issue.

The factors influencing the impact of rare earth elements on mining?carbide

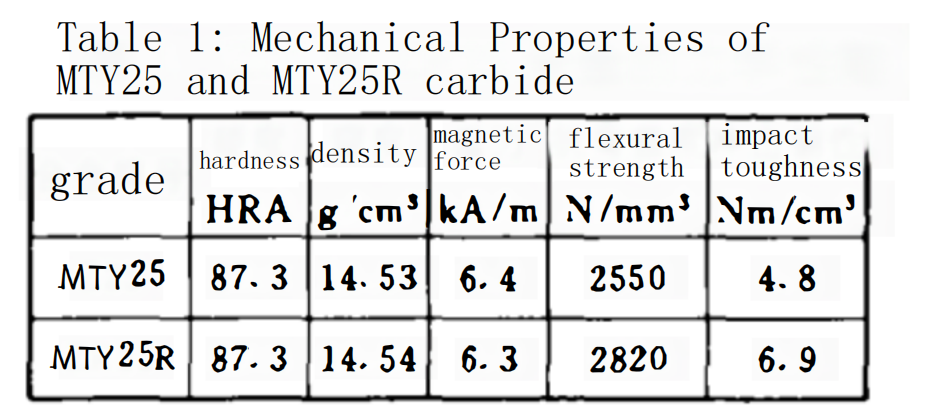

We selected our factory’s mining?carbide?MTY25 and added a mixture of rare earth elements before wet grinding to prepare a blend called MTY25R. Both of these were high-temperature sintered to create experimental materials for performance testing.

From Table 1, it can be seen that the addition of rare earth elements has increased the flexural strength and impact toughness values of the mining carbide, with minimal impact on hardness, density, and magnetic properties. This indicates that the inclusion of rare earth elements enhances the plastic deformation capability of the bonding phase and its bond strength with the hard phase at the interface.

The addition of rare earth elements to the carbide?can enrich the carbide?with impurity elements, improve the distribution of interface impurities, purify grain boundaries, strengthen the bonding phase, and alter the composition of the Co phase. We believe that apart from strengthening the Co matrix of the bonding phase, rare earth elements primarily inhibit the phase transformation of Co.

We subjected MTY25R and MTY25 mining?carbide?to an electrolytic dissolution method, selectively dissolving the surface layer of WC, leaving the Co phase for quantitative X-ray analysis. We found that the addition of rare earth elements increases the content of ductile α-Co in the carbide?from around 60% to over 90%, significantly enhancing the plasticity of the Co phase. Consequently, this improvement results in higher flexural strength and impact toughness for the carbide.

The experimental data’s validation?for the results

To understand the differences in performance between carbides with and without rare earth element additions during actual usage, we conducted the following two steps:

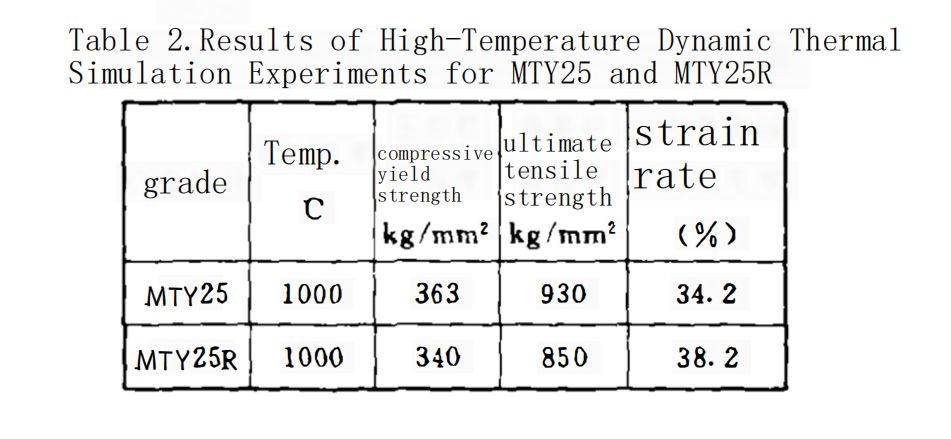

1Dynamic thermal simulation tests were conducted to simulate the changes in carbide?performance under operating conditions and to determine the influence of rare earth elements on the carbide’s performance.

2Field trials were carried out at mining production sites to assess the carbide’s service life. We conducted high-temperature dynamic thermal simulation tests at Central South University in China (as shown in Table 2).

The test results indicate that adding rare earth elements to the carbide?reduces the carbide’s thermal strength while increasing its thermal plasticity and high-temperature toughness (represented by the total area under the stress-strain curve). This effect is similar to the increase in Co content. carbides containing rare earth elements exhibit excellent thermal plasticity and toughness, allowing them to better accommodate the complex thermal stress plastic deformation differences in high-temperature environments. Therefore, carbides with rare earth element additions can improve their performance in use, enhance wear resistance, and extend their service life.

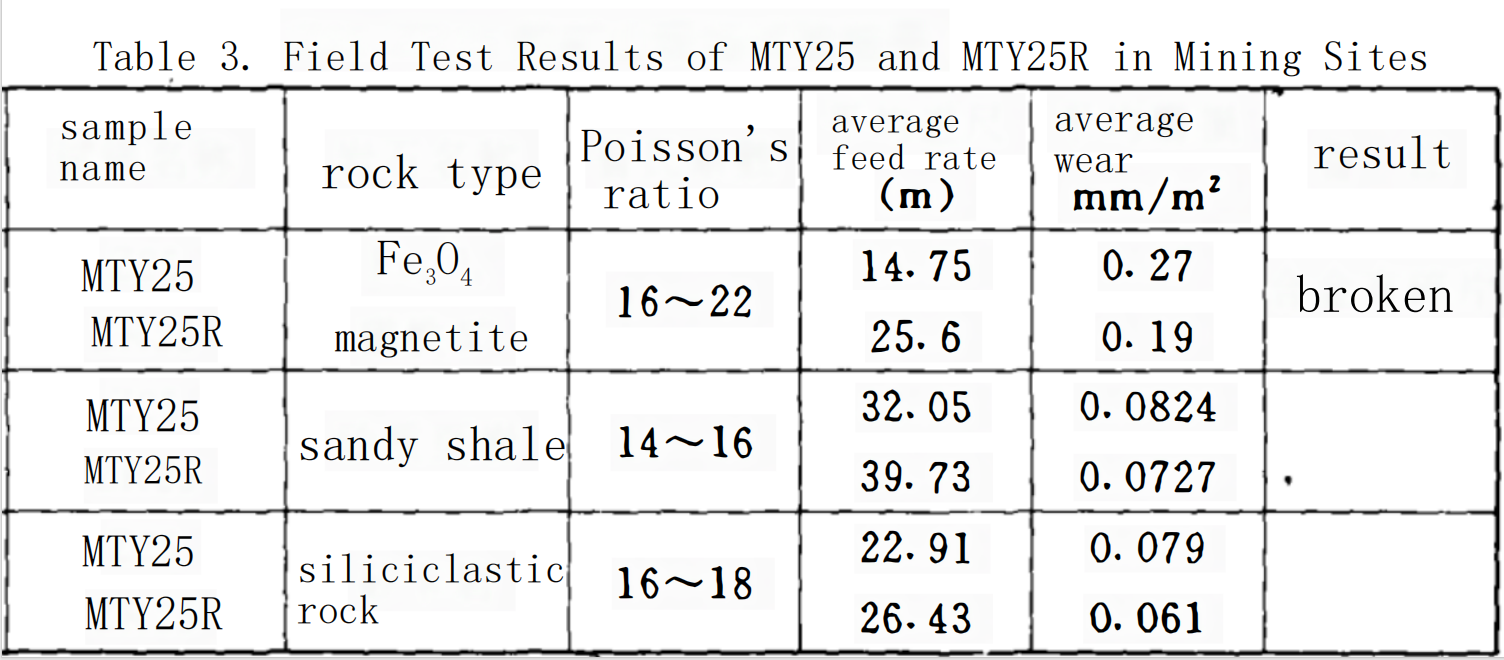

The results in Table 3 demonstrate that the MTY25R carbide?with added rare earth elements shows an improvement in both service life and wear resistance compared to the MTY25 carbide?without rare earth elements. Particularly, in the test conducted at the Lugu Iron Mine, the MTY25R carbide?exhibited excellent performance.

The Lugu Iron Mine is one of the locations in China known for having the hardest rocks. Typically, drilling bits with carbide?insert thicknesses of 16mm are used for ore extraction in this region, while the carbide?inserts we used in our test were 10mm thick. However, during the entire experiment, no instances of carbide?fracture were observed with the rare earth element-added carbide?inserts. The service life of these inserts was also significantly extended compared to the inserts without rare earth elements. This strongly supports the conclusion that the addition of rare earth elements can indeed enhance the carbide’s flexural strength and impact toughness, improving its performance in real-world applications.

Wniosek

1Adding a certain amount and form of rare earth elements to mining?carbides can enhance the carbide’s flexural strength and impact toughness, thus improving wear resistance and extending the carbide’s service life.

2The addition of rare earth elements has a similar effect to increasing the Co content in the carbide, enhancing its thermal plasticity and toughness.