Lathe

Types of lathe

There are numerous types of lathes, with approximately 77 different types, according to statistics from a machining engineer’s handbook. Some of the more typical categories include: engine lathes, single-axis automatic lathes, multi-axis automatic or semi-automatic lathes, turret or capstan lathes, crankshaft and camshaft lathes, vertical lathes, floor and horizontal lathes, copying lathes, and multi-tool lathes, among others. In our mechanical industry, the most commonly used ones are vertical lathes and horizontal lathes, and you can find these two types of lathes in almost any place where machining is done.

Applicable scope of lathe processing

We primarily select several typical lathe types to introduce their machining applications:

- Horizontal Lathe: Suitable for turning inner and outer cylindrical surfaces, conical surfaces, contour turning, and circular grooves. It can also perform operations such as turning profiles, various threading tasks, drilling, reaming, tapping, thread chasing, and knurling, among others. Although standard horizontal lathes have a relatively lower level of automation and involve more auxiliary time during the machining process.

- Vertical Lathe: Suitable for machining various frames, housing-type parts, and both internal and external cylindrical surfaces, conical surfaces, end faces, grooves, cutting, drilling, reaming, and other processes. With additional attachments, it can also perform operations like thread cutting, end facing, profiling, milling, and grinding.

Machining accuracy of lathe

- Typical machining accuracy for a standard horizontal lathe is as follows:

- Roundness: 0.015mm

- Cylindricity: 0.02/150mm

- Flatness: 0.02/¢150mm

- Surface Roughness: 1.6Ra/μm

- Machining accuracy for a vertical lathe is as follows:

- Roundness: 0.02mm

- Cylindricity: 0.01mm

- Flatness: 0.03mm

The mentioned machining accuracy values are relative reference values and may not apply to all lathe machines. Many lathe machines have certain tolerances based on the specific requirements of the manufacturer and the assembly conditions.

Milling machine

Types of milling machine

There are also many types of milling machines, with over 70 different types according to a certain machining engineer’s handbook. Some typical categories include:

- Benchtop milling machines

- Overarm and ram-type milling machines

- Gantry milling machines

- Horizontal milling machines

- Profiling milling machines

- Vertical lifting table milling machines

- Horizontal lifting table milling machines

- Bed-type milling machines

- Toolroom milling machines

Applicable scope?of milling machine

- Due to the multitude of types and structures of milling machines, as well as variations in their applicability, we will provide an overview of the machining capabilities for two typical milling machines commonly used today: Vertical Machining Centers (VMCs) and Gantry Machining Centers.

- Vertical Machining Center (VMC): The Vertical Machining Center, as shown in the figure above, is essentially a vertical CNC milling machine with a tool magazine. Its main feature is the use of multi-edge rotating cutting tools for machining. It can perform various operations such as milling flat surfaces, grooves, toothed parts, spiral surfaces, and various curved surfaces. With the application of CNC technology, the machining range of this type of machine tool has greatly expanded. In addition to various milling operations, it can also perform compound processes such as drilling, boring, tapping, and threading on workpieces. It has practical and widespread applications.

- Gantry Machining Center: Compared to Vertical Machining Centers, Gantry Machining Centers are essentially a combination of CNC gantry milling machines with a tool magazine. In terms of machining capabilities, Gantry Machining Centers offer nearly all the capabilities of conventional Vertical Machining Centers. Moreover, they can accommodate larger workpieces in terms of external dimensions and provide significant advantages in machining efficiency and precision. The use of five-axis gantry machining centers, in particular, has greatly expanded the machining range. This development has laid the foundation for the advancement of China’s manufacturing industry toward higher precision and sophistication.

Machining accuracy of milling machine

-

Vertical Machining Center (VMC):

- Flatness: 0.025/300mm

- Surface Roughness: 1.6Ra/μm

- Gantry Machining Center:

- Flatness: 0.025/300mm

- Surface Roughness: 2.5Ra/μm

Planer

Types of planer

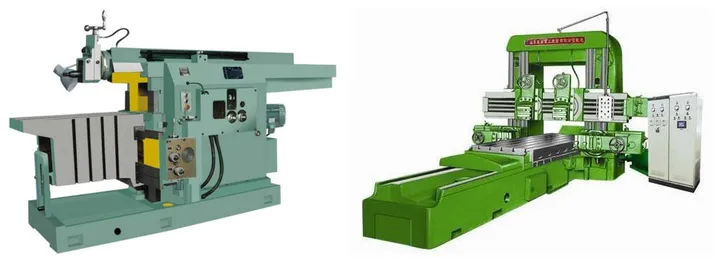

In comparison to lathes and milling machines, there are fewer types of planers. According to the Mechanical Machinist’s Handbook, there are approximately 21 different types. Some of the more typical types include cantilever planers, gantry planers, bullhead planers, edge and die planers, etc. Within these categories, there are many subtypes of planer machines. However, in the mechanical industry, the most commonly used and widely adopted types are probably bullhead planers and gantry planers.

Applicable scope of planer

The planer’s cutting motion primarily involves a reciprocating linear movement relative to the workpiece. It is suitable for machining parts with characteristics such as flat surfaces, inclined surfaces, and concave-convex surfaces. It can also be used for planing various curved surfaces.

Machining accuracy of planer

The machining precision of planing can generally achieve accuracy levels ranging from IT10 to IT7, especially for the machining of long guide rail surfaces on some large machine tools. It can even replace grinding processes, which is referred to as the “precision planing instead of precision grinding” method.

Grinding machine

Types of grinding machine

There is a wide variety of grinding machines, with approximately 194 different types, according to the statistics from a certain mechanical machining engineer’s handbook. These machines can be broadly categorized into various types, including bench grinders, cylindrical grinders, internal grinders, surface grinders, coordinate grinders, guide rail grinders, tool and cutter grinders, and more.

Applicable scope of grinding machine

- Cylindrical Grinder: This type of grinder is primarily used for machining the external surfaces and shoulder ends of cylindrical or conical workpieces. Due to its excellent adaptability and machining precision, cylindrical grinders are widely used in the machining of high-precision parts in the mechanical industry, especially in the final finishing stages of these components. Cylindrical grinders not only ensure the geometric dimensions of machined parts but also achieve the required surface finish, making them an indispensable piece of equipment in machining processes.

- Surface Grinder: Surface grinders are mainly used for machining flat surfaces, steps, and side surfaces of workpieces. They are also widely used in the mechanical industry, especially for the surface finishing of high-precision parts. Surface grinders are crucial for maintaining machining accuracy. In some equipment assembly industries, using a surface grinder is considered an essential skill for assembly personnel. This is because surface grinders are used for the grinding and adjustment of various shims and components during the assembly process.

Machining accuracy of grinding machine

- Cylindrical Grinder Precision: Roundness and Cylindricity: 0.003mm Surface Roughness: 0.32Ra/μm

- Surface Grinder Precision: Parallelism: 0.01/300mm Surface Roughness: 0.8Ra/μm

From the above machining precision values, it is evident that grinding machines, compared to earlier machining equipment such as lathes, milling machines, and planers, can achieve higher dimensional tolerance accuracy and surface finish. Therefore, grinding machines are widely and commonly used in the precision machining processes of many components.

Boring machine

Types of boring machine

Compared to the previous types of machining equipment, boring machines are relatively niche. According to statistics from a mechanical machining engineer’s manual, there are approximately 23 different types. They can be categorized into the following main types: deep hole boring machines, coordinate boring machines, vertical boring machines, horizontal milling and boring machines, precision boring machines, and more. Among these, coordinate boring machines are the most common and widely used in our mechanical industry.

Applicable scope of boring machine

Coordinate boring machines are a type of precision machine tool equipped with precise coordinate positioning devices. They are mainly used for boring holes with high requirements for size, shape, and positional accuracy. These machines can perform various operations such as drilling, reaming, tapping, chamfering, facing, grooving, milling, coordinate measuring, precision scaling, and engraving. They possess extensive and reliable machining capabilities.

Machining accuracy of boring machine

The hole diameter accuracy achieved by coordinate boring machines is typically in the range of IT6-7, with a surface roughness of 0.4-0.8Ra/μm.

Drilling machine

Types of drilling machine

Drilling machine is the most widely used machining equipment in the mechanical industry, and almost every machining factory will have one. According to statistics from a certain mechanical machining engineer’s handbook, there are approximately 38 different types of drilling machines. They can be categorized into the following main types: coordinate drilling machines, deep hole drilling machines, radial drilling machines, bench drilling machines, vertical drilling machines, horizontal drilling machines, mill-drill machines, center drilling machines, and more. Among these, the radial drilling machine is the most commonly used in the mechanical industry.

Applicable scope of drilling machine

The task of a drilling machine is to perform operations such as hole enlargement, tapping, countersinking, and threading. However, it has a significant limitation in terms of positional accuracy for hole locations. Therefore, for components that require high positional accuracy for holes, drilling machines are typically not the preferred choice.

Machining accuracy of drilling machine

In general, drilling machines do not offer significant machining precision.