The following few aspects are closly connected with the malfunction of mechanical parts:

(1) Integral fracture (2) excessive residual deformation (3) surface malfunction?of parts (4) malfunction?caused by malfunction?of normal working conditions

1. Why thread connection often needs anti loosing?

A: generally, the threaded connection can meet the self-locking condition without automatic loosening, but under vibration or impact load, or when the temperature changes greatly, the connecting nut may gradually loosen. The main reason for thread looseness is the relative rotation between thread pairs. Therefore, in actual design, anti looseness measures must be taken. The commonly used measures are as follows: 1. Friction anti looseness – to maintain the friction between thread pairs to prevent looseness, such as adding spring washer and pushing double nuts; 2. Mechanical anti looseness – to use stop parts to ensure anti looseness, which is often used It is groove nut and split pin, etc.; 3. Destroy thread pair anti loosing – destroy and change thread pair relationship, such as impact method.

2.What is the purpose of tightening in threaded connection?

A: the purpose of tightening in the threaded connection is to make the bolt produce preload, and the purpose of preloading is to enhance the reliability and tightness of the connection, so as to prevent the gap or relative sliding between the connected parts after loading. The effective way to control the tightening force is to measure the torque wrench or constant torque wrench, when the required torque is reached, the tightening can be done; or the method of measuring the bolt elongation is used to control the preload.

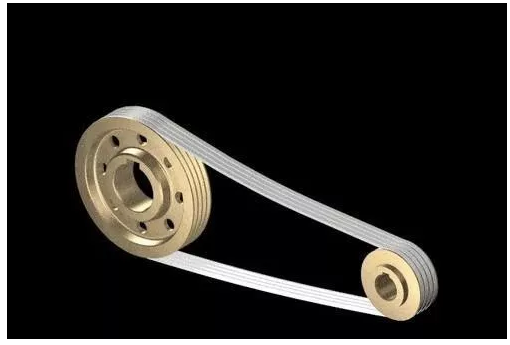

3.What is the difference between elastic sliding and slipping of belt drive?

A: elastic sliding is an inherent characteristic of belt drive, which is inevitable. When there is a tension difference and the belt is an elastic body, elastic sliding will occur. Skid is caused by overload, which is a form of malfunction. It can be avoided and must be avoided. Cause: slip occurs on the small pulley. The greater the external load, the greater the tension difference between the two sides, which leads to the increase of the elastic sliding area. When the elastic sliding occurs in the wrap angle, the slip occurs. Elastic sliding is a quantitative change, while sliding is a qualitative change. Small wheel diameter, small wrap angle, small friction contact area, easy to slip.

A: because: the main malfunction mode of gray cast iron and aluminum iron bronze turbine is tooth surface gluing, and the gluing is related to the sliding speed, so the allowable contact stress is related to the tooth sliding speed. The main malfunction mode of cast tin bronze turbine is tooth surface pitting, which is caused by contact stress, so the allowable contact stress has nothing to do with sliding speed.

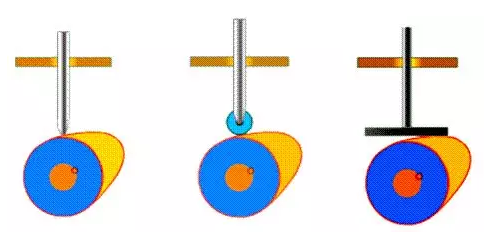

5.The common motion law, impact characteristics and application of cam follower are described.

A: the law of constant velocity motion, the law of constant acceleration and deceleration motion, and the law of simple harmonic motion (the law of cosine acceleration motion);

The law of constant velocity motion has rigid impact, which is used in the situation of low speed and light load;

The law of equal acceleration and equal deceleration has flexible impact, which is used in the situation of medium and low speed; the law of simple harmonic motion (the law of the acceleration of the remaining four chords) has flexible impact when there is a stop interval, which is used in the situation of medium and low speed, and when there is no stop interval, it has no flexible impact, which is used in the situation of high speed.

6. The basic law of tooth profile engagement is briefly described.

No matter the tooth profile contacts at any position, the common normal made by passing through the contact point must pass through a certain point on the connecting line, so as to ensure the constant transmission ratio.

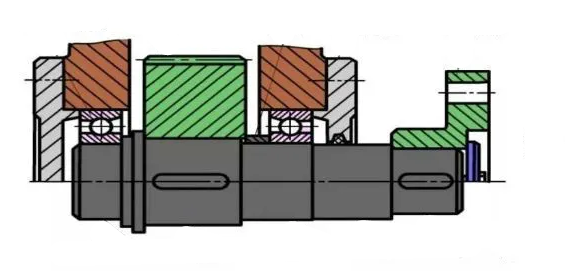

7. What are the methods of circumferential fixation of shaft parts?

Circumferential fixation: key connection, spline connection, interference fit connection, set screw, pin connection, expansion connection

8. What are the main types of axial fixation methods for shaft parts?

Axial fixation: the shaft shoulder, collar, sleeve, shaft end baffle, elastic gear ring, shaft shoulder, collar and sleeve are fixed reliably and can bear large axial force; elastic gear ring can bear smaller axial force; shaft end baffle is used for fixing parts at the shaft end.

9. Why must the heat balance calculation be carried out for closed worm drive?

The worm drive has relative sliding and high friction. Because of the poor heat dissipation of closed worm drive, it is easy to produce glue, so heat balance calculation is needed.

10. Which two strength calculation theories are available in the calculation of gear strength?

A: the calculation of contact fatigue strength and bending fatigue strength of tooth root, the contact fatigue strength of tooth surface is aimed at the fatigue pitting malfunction of tooth surface and bending fatigue strength of tooth root is aimed at the fatigue fracture of tooth root. The gear transmission is closed soft tooth surface transmission, and its design criterion is to check the bending fatigue strength of the tooth root according to the contact fatigue strength of the tooth surface.

11. What is the function of the coupling and clutch? What is the difference between them?

A: the function of coupling and clutch is to connect the two shafts to rotate together and transmit torque. The difference between them is that the two shafts connected with coupling cannot be separated in operation, only after the parts are removed after the machine is shut down, and the two shafts can be separated or engaged at any time during the operation of the machine.

12. What are the necessary conditions for oil film loading?

Answer: wedge gap must be formed between two surfaces of relative motion; 2. The two surfaces separated by oil film must have a certain relative sliding speed, and its direction shall ensure that lubricating oil is imported from large port and from small port; 3. Lubricating oil must have certain viscosity and oil supply shall be sufficient.

13. The meaning, characteristics and application of bearing type 7310 are briefly described.

A: code meaning: 7 – angular contact ball bearing; (0) – normal width, 0 – can be omitted or not written; 3 – diameter series is medium series; 10 – bearing inner diameter is 50mm.

Features and applications: it can bear both radial load and single direction axial load, and the ultimate speed is high, and it is generally used in pairs.

14. What transmission should be arranged at the highest speed level in the transmission system composed of gear transmission, belt drive and chain drive? What drive is arranged at the lowest speed level? Why do you want to arrange this way?

A: generally, the belt drive is arranged at the highest level, and the chain drive is arranged at the lowest level; the belt drive has the characteristics of smooth transmission and buffering vibration absorption, so it is placed at high speed level, which is favorable for the motor; the chain drive is noisy when working and is suitable for working in low speed occasions, so it is generally arranged at low speed level.

15. What is the reason for the uneven speed of chain transmission? What are the main factors that affect it? What conditions can the instantaneous transmission ratio be constant?

Answer: 1) the main reason for the uneven speed of chain transmission is the polygonal effect of chain drive; 2) the main factors are: chain speed, chain pitch and sprocket tooth number; 3) when the number of teeth of large and small sprockets is equal to z1=z2 (R1 = R2), and the center distance of transmission is just the whole number of pitch P, the instantaneous transmission ratio is constant, that is, constant to 1.

16. In the cylindrical gear reducer, why is the width of pinion gear B1 slightly larger than that of big gear B2? When calculating strength, does the tooth width coefficient ψ d be calculated by B1 or B1? Why?

Answer: 1) in order to prevent the working load of the large and small gears from increasing the working load due to the axial dislocation caused by the assembly error, the width of the pinion teeth B1 is slightly larger than the width of the big gear B2; 2) the tooth width coefficient ψ D is calculated according to the width of the big gear, B2; because the big gear tooth width B2 is the actual contact width of a pair of cylindrical gears.

17. Why should the diameter of small pulley D1 ≥ Dmin and the angle of driving wheel package α 1 ≥ 120 ° be made in the drive of deceleration belt? Generally, the band speed is recommended to be between (5-25) m / s. what will the influence of belt speed beyond this range?

Answer: 1) the smaller the diameter of the small pulley, the greater the bending stress of the belt, so to avoid the excessive bending stress of the belt, the minimum diameter of the small pulley should be limited; 2) the driving wheel envelope angle α 1 affects the maximum effective tension of the belt, the smaller the maximum effective tension of the α 1 belt, the smaller the maximum effective tension, in order to increase the maximum effective tension of the belt drive and prevent slipping, generally α 1 ≥ 120 °; 3) if the belt speed is too small, it means the small pulley is straight If the diameter is too small, the effective tension Fe required will be too large, which will lead to too many roots Z of the belt, which will make the belt drive structure larger; if the belt speed is too large, the centrifugal force FC is too large, so the belt speed should be (5-25) M / s.

18. Advantages and disadvantages of rolling screw.

A: advantages: 1) the wear is very small, and the clearance can be eliminated by adjustment method and certain pre deformation can be generated to increase the rigidity. Therefore, the transmission accuracy is very high. 2) it is not self-locking, and can change straight line movement into rotation motion. Disadvantages: 1) complex structure, difficult to manufacture, 2) in some mechanisms, self-locking mechanism is required to prevent reversal.

19. Key selection principle?

Answer: type selection and size selection: type selection should be based on the structural characteristics of key connection, use requirements and working conditions The size selection shall be determined according to the requirements of standard specifications and strength. The dimension of key is the section dimension (key width b* key height h) and length L. the section dimension b * h is selected by the diameter of the shaft D, and the key length l can be determined by the length of the hub, that is, the key length L is less than the hub length, while the guide flat key determines the general hub length L ‘~ (1.5-2) according to the length of the hub and the sliding distance )*d。