Metalurgia proszków to proces wytwarzania proszku metalu i wykorzystania proszku metalu (lub mieszaniny metalu i niemetalu) jako surowca do otrzymania cz??ci i produktów poprzez formowanie i spiekanie. Jako g?ówny surowiec przemys?owy, proszek metalowy jest szeroko stosowany w maszynach, metalurgii, przemy?le chemicznym i materia?ach lotniczych. Proszek metalowy jest podstawowym surowcem przemys?u metalurgii proszków. Jej wydajno?? i jako?? determinuj? rozwój przemys?u metalurgii proszków.

Metal powder is usually an aggregate of metal particles less than 1mm. There is no uniform provision for the division of granularity interval. The common classification method is as follows: the particles with a particle size of 1000 ~ 50 μ m are conventional powders; 50 ~ 10 μ m fine powder; 10 ~ 0.5 μ m is called very fine powder< 0.5 μ m is called ultrafine powder; 0.1 ~ 100nm is called nano powder. Each powder particle may be one crystal or composed of many crystals, depending on the particle size and preparation method.

2. Preparation method of metal powder

At present, there are dozens of methods for industrial production of powder, but according to the substantive analysis of the production process, it is mainly divided into two categories: mechanical method and physicochemical method. It can be obtained not only from the direct refinement of solid, liquid and gaseous metals, but also from the reduction, pyrolysis and electrolytic transformation of metal compounds in different states. Carbides, nitrides, borides and silicides of refractory metals can generally be prepared directly by chemical combination or reduction chemical combination. Due to different preparation methods, the shape, structure and particle size of the same powder are often very different.

The choice of metal powder production method depends on raw materials, powder type, performance requirements of powder materials and powder production efficiency. With the more and more extensive application of powder metallurgy products, the requirements for the size, shape and properties of powder particles are higher and higher. Therefore, the powder preparation technology is also developing and innovating to meet the requirements of particle size and properties.

2.1 mechanical physical method

Mechanical method is a processing method that breaks metal into required particle size powder with the help of external mechanical force. The chemical composition of the material is basically unchanged during the preparation process. At present, the commonly used methods are ball milling and grinding, which have the advantages of simple process and large output. It can prepare some ultra-fine powders of high melting point metals and alloys that are difficult to obtain by conventional methods.

2.1.1 ball milling method

Mechanism: ball milling method is mainly divided into rolling ball method and vibration ball milling method. This method makes use of the mechanism that metal particles are broken and refined due to strain at different strain rates.

Application: this method is mainly applicable to the preparation of sb, Cr, Mn, Fe Cr alloy and other powders.

Advantages and disadvantages: it has the advantages of continuous operation and high production efficiency. It is suitable for dry grinding and wet grinding. It can prepare the powder of a variety of metals and alloys. The disadvantage is that the selectivity of materials is not strong, and it is difficult to grade in the process of powder preparation.

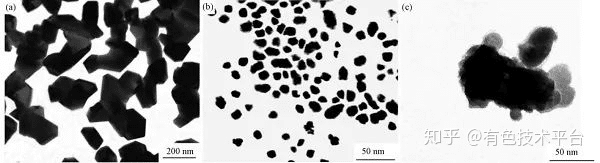

Fig. 1 TEM photos of antimony powder samples obtained by ball milling for 12h (a), 18h (b) and 24h (c) at 150r / min

2.1.2 grinding method

Mechanism: the grinding method is to spray the compressed gas into the grinding area after passing through a special nozzle, so as to drive the materials in the grinding area to collide with each other and rub into powder; After the air flow expands, it enters the classification area with the rise of materials, and the materials reaching the particle size are sorted out by the vortex classifier. The remaining coarse powder returns to the grinding area for grinding until the required particle size is separated.

Application: it is widely used in ultra-fine grinding of non-metallic, chemical raw materials, pigments, abrasives, health drugs and other industries.

Advantages and disadvantages: because the grinding method adopts dry production, the dehydration and drying of materials are omitted; The product has high purity, high activity, good dispersion, fine particle size and narrow distribution, and the particle surface is smooth. However, the grinding method also has some disadvantages, such as high equipment manufacturing cost, continuous inert gas or nitrogen must be used as compressed gas source in the production process of metal powder, large gas consumption, which is only suitable for crushing and pulverizing brittle metals and alloys.

2.1.3 atomization method

Mechanism: atomization method generally uses high-pressure gas, high-pressure liquid or high-speed rotating blades to break the molten metal or alloy at high temperature and high pressure into fine droplets, and then condense in the collector to obtain ultra-fine metal powder. There is no chemical change in this process. Atomization is one of the main methods to produce metal and alloy powder. There are many atomization methods, such as double flow atomization, centrifugal atomization, multi-stage atomization, ultrasonic atomization technology, tight coupling atomization technology, high-pressure gas atomization, laminar flow atomization, ultrasonic tight coupling atomization and hot gas atomization.

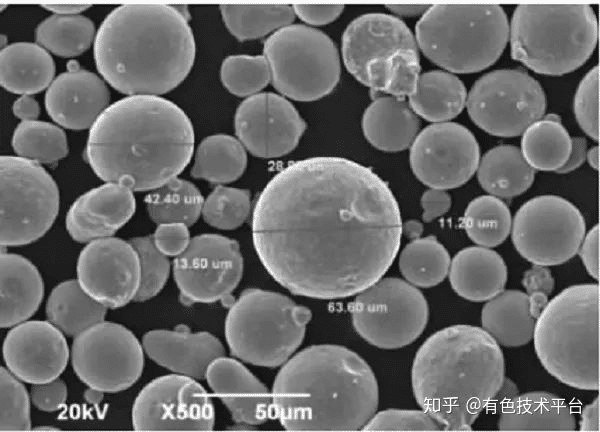

Application: atomization method is usually used in the production of metal powders such as Fe, Sn, Zn, Pb and Cu, as well as the production of alloy powders such as bronze, brass, carbon steel and alloy steel. The atomization method meets the special requirements of metal powder for 3D printing consumables. Figure 3 shows the microstructure of stainless steel powder from a German manufacturer.

Advantages and disadvantages: atomized powder has the advantages of high sphericity, controllable powder particle size, low oxygen content, low production cost and adaptability to the production of various metal powders. It has become the main development direction of high-performance and special alloy powder preparation technology. However, atomization method has the disadvantages of low production efficiency, low yield of ultra-fine powder and relatively large energy consumption.

Fig. 2 microstructure of 3D printed stainless steel powder from a German manufacturer

2.2 physical chemical method

Physicochemical method refers to the production method of ultrafine powder by changing the chemical composition or agglomeration state of raw materials in the process of powder preparation. According to different chemical principles, it can be divided into reduction method, electrolysis method and chemical replacement method.

2.2.1 reduction method

Mechanism: reduction method is a method of preparing metal or alloy powder by reducing metal oxides or metal salts with reducing agent under certain conditions. It is one of the most widely used powder making methods in production. Common reducing agents include gas reducing agents (such as hydrogen, decomposed ammonia, converted natural gas, etc.), solid carbon reducing agents (such as charcoal, coke, anthracite, etc.) and metal reducing agents (such as calcium, magnesium, sodium, etc.). The hydrogenation dehydrogenation method with hydrogen as the reaction medium is the most representative preparation method. It uses the characteristics of easy hydrogenation of raw metal to hydrogenate the metal with hydrogen at a certain temperature to generate metal hydride, and then breaks the obtained metal hydride into powder with desired particle size by mechanical method, Then, the hydrogen in the crushed metal hydride powder is removed under vacuum to obtain the metal powder.

Application: mainly used in the preparation of metal (alloy) powders such as Ti, Fe, W, Mo, Nb and W-Re. For example, titanium (powder) begins to react violently with hydrogen at a certain temperature. When the hydrogen content is greater than 2.3%, the hydride is loose and easy to be crushed into fine particles of titanium hydride powder. Titanium powder can be obtained by decomposing it at a temperature of about 700 ℃ and removing most of the hydrogen dissolved in the titanium powder.

Advantages and disadvantages: the advantages are simple operation, easy control of process parameters, high production efficiency and low cost, which is suitable for industrial production; The disadvantage is that it is only applicable to metal materials that are easy to react with hydrogen and become brittle and fragile after hydrogen absorption.

2.2.2 electrolytic method

Mechanism: electrolysis is a method to deposit and precipitate metal powder at the cathode by electrolysis of molten salt or salt aqueous solution.

Application: electrolytic aqueous solution can produce metal (alloy) powders such as Cu, Ni, Fe, Ag, Sn and Fe Ni, and electrolytic molten salt can produce metal powders such as Zr, Ta, Ti and Nb.

Advantages and disadvantages: the advantage is that the purity of the prepared metal powder is high, and the purity of the general elemental powder can reach more than 99.7%; In addition, the electrolysis method can well control the particle size of the powder and produce ultra-fine powder. However, the power consumption of electrolytic pulverization is large and the pulverization cost is high.

Fig. 4 device for preparing iron powder by ultrasonic electrolysis

2.2.3 hydroxyl method

Mechanism: some metals (iron, nickel, etc.) and carbon monoxide are synthesized into metal carbonyl compounds, which are reheated and decomposed into metal powder and carbon monoxide.

Appliczation: in industry, it is mainly used to produce fine and ultra-fine powders of nickel and iron, as well as alloy powders such as Fe Ni, Fe Co and Ni Co

Advantages and disadvantages: the powder prepared in this way is very fine and high purity, but the cost is high.

2.2.4 chemical replacement method

Mechanism: chemical replacement method is to replace the less active metal from the metal salt solution with the highly active metal according to the activity of the metal, and further treat and refine the metal (metal powder) obtained by replacement with other methods.

Application: this method is mainly applied to the preparation of inactive metal powders such as Cu, Ag and Au.

The summary of preparation methods of metal powder is shown in Table 1.

3. Summary

With the progress of technology, metal powder has been developed and applied in metallurgy, chemical industry, electronics, magnetic materials, fine ceramics, sensors and so on, showing a good application prospect, and metal powder shows a development trend towards high purity and ultra-fine (nano). Although the preparation methods of ultrafine metal powder are various, and different methods can be selected according to the application and economic and technical requirements, each method has certain limitations and many problems need to be solved and improved. At present, the most widely used methods for preparing metal powder are reduction method, electrolysis method and atomization method; In addition, based on the improvement of the traditional production process, many new production processes and methods have been obtained, such as vacuum evaporation condensation method, ultrasonic atomization method, rotating disc atomization method, double roll and three roll atomization method, multistage atomization method, plasma rotating electrode method, arc method, etc. In the preparation methods of metal powder, although many methods have been applied in practice, there are still two main problems, namely, small scale and high production cost. In order to promote the development and application of metal powder materials, it is necessary to comprehensively utilize different methods, learn from each other, and develop process methods with greater production and lower cost.