Development history of shape memory alloy

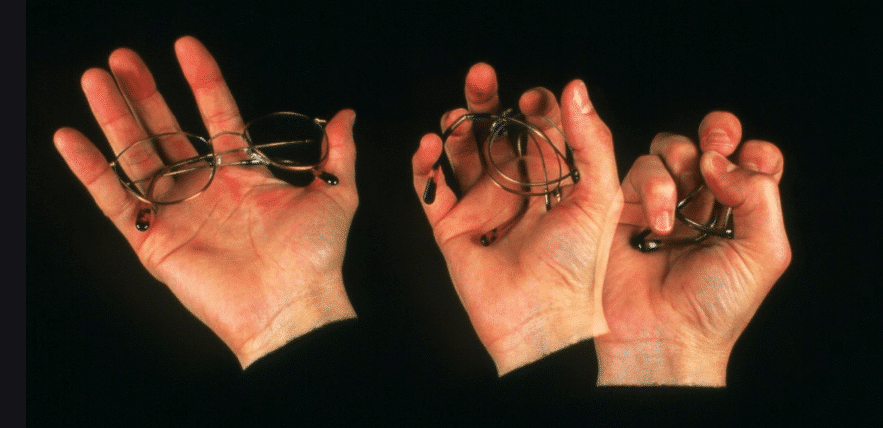

Shape memory alloy is a kind of shape memory material with excellent properties. When it is affected by external force or magnetic change, it can keep its previous state, which is called shape memory effect. The application of these materials is very simple, in which the materials are easy to deform by applying external force. When they are heated to a certain temperature by external or internal heating, they will shrink or return to their original shape. In 1932, Swedish physicists first discovered this shape memory effect in Au CD alloy. By 1938, greninger and mooradian first observed this shape memory effect in Cu Zn and Cu Sn alloys. Until 1969, SMA was successfully applied commercially for the first time. Raychem company successfully applied NiTi alloy as a pipe joint to the oil pressure system of F14 fighter in the United States, and achieved good sealing performance of the oil pressure system.

Shape memory effect

The shape memory effect of shape memory alloy is essentially related to the martensitic transformation in the alloy. The shape memory alloy exists in the form of austenite at higher temperature and martensite at lower temperature. When SMA is heated, it begins to change from martensitic phase to austenitic phase. A s is

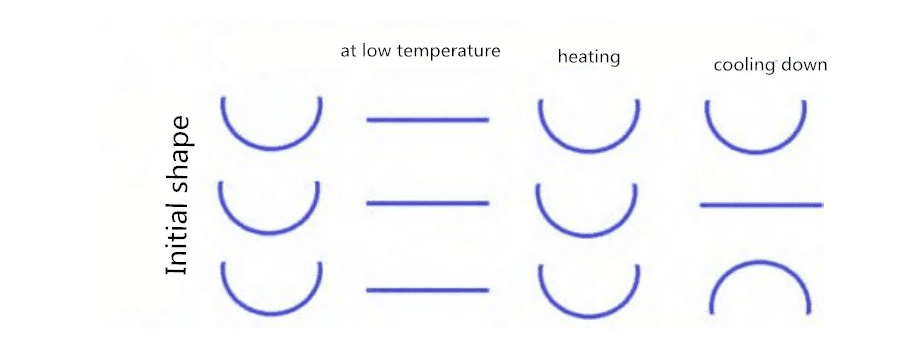

It is defined as the temperature at which austenitic transformation begins, and AF as the temperature at which austenitic transformation ends. When SMA is heated above a s temperature, the martensitic phase will gradually change back to the austenite phase and return to the original shape at high temperature, which can also be carried out under high load conditions. In the cooling process, the starting temperature from austenite to martensite is defined as MS, and the temperature at the end of martensite transformation is defined as MF. The temperature at which martensitic transformation is no longer induced by stress is defined as MD. Above this temperature, SMA deforms under the action of external force, and immediately returns to its original shape after unloading. Shape memory alloys have three different types of memory effects (as shown in Figure 1), which are characterized as follows:

① One way memory effect. When the temperature is reduced, the alloy will deform, and then it will return to the state before deformation by increasing the temperature, that is, there is shape memory effect in the heating process;

② Two way memory effect. When the alloy returns to the state at high temperature during heating, and returns to the shape at low temperature when the temperature is reduced. Because the two-way memory effect can only be obtained through proper “training” process and the strain at high temperature will be greatly reduced, so it has less commercial application. Heat force cycling is a kind of “training” method to realize the two-way shape memory effect. It achieves the purpose of “training” by cycling between austenite and specific martensite variants;

③ Whole process memory effect. It refers to the state when the alloy recovers to high temperature during the heating process. When the temperature is reduced to low temperature, the shape changes to the opposite shape when it changes to high temperature.

The shape memory effect is a non diffusion solid phase martensitic transformation. In addition, there are other phase transformation processes related to shape memory, such as R-phase transformation, which generally occurs in an intermediate phase transformation from austenite to martensite. There is thermal hysteresis in the reverse transformation of martensite, which is an index to measure the temperature difference between heating and cooling (i.e. Δ t = af-ms). This thermal hysteresis property is very important, and the thermal hysteresis of SMA material needs to be considered carefully in the process of target technology application, for example, for fast drive application, smaller thermal hysteresis is needed, while for pipeline connection, larger thermal hysteresis is needed to ensure that the predefined shape is maintained in a larger temperature range. The physical and mechanical properties (thermal conductivity, thermal expansion coefficient, resistivity, Young’s modulus, etc.) of some SMA before and after phase transition are also different. Austenite phase structure is relatively hard and has higher Young’s modulus, while martensite structure is softer and more malleable, that is, it can be easily deformed by applying external force.

Introduction of shape memory alloy materials

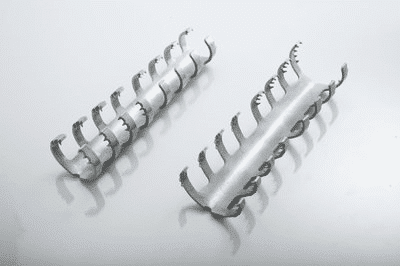

NiTi shape memory alloy has been widely used in biomedical fields such as alloy stent, minimally invasive medical devices, orthopedic surgery, brain surgery and stomatology due to its excellent biocompatibility and mechanical properties.

However, due to the obvious limitations or shortcomings of SMA, such as high manufacturing cost, limited recoverable deformation and service temperature, other types of shape memory materials are being explored.

High temperature shape memory alloy

Due to the higher and higher requirements for the service temperature of high temperature shape memory alloy, many researchers have increased the service temperature of shape memory alloy by adding the third element alloy in NiTi alloy. In fact, the high temperature shape memory alloy is defined as the shape memory alloy that can be used above 100 ℃, but due to the large

Most high temperature shape memory alloys show poor ductility and fatigue resistance at room temperature, so it is difficult to process and “train”, so the cost of manufacturing them is very expensive. Ferromagnetic shape memory alloy

Compared with the traditional temperature controlled shape memory alloy, the ferromagnetic shape memory alloy has larger output strain and higher response frequency. This is because the energy propagates through the magnetic field during the service process and is not affected by the thermal conductivity and heat dissipation conditions of the alloy material. Its shape memory effect is to excite twins through the external magnetic field

The preferred reorientation among the martensitic variants results in the macro shape deformation of the alloy. Ferromagnetic shape memory alloy can not only provide the same specific power as traditional memory alloy, but also transmit at a higher frequency. However, in general, ferromagnetic shape memory alloy will encounter similar design problems with traditional memory alloy in the application process. In addition, the hardness of ferromagnetic shape memory alloy is very large and brittle, so it can only be processed and operated at low temperature. Therefore, it is difficult to shape and shape ferromagnetic shape memory alloy, and it is not suitable for high temperature and high strength environment at present. Therefore, it is still necessary to further study the existing ferromagnetic shape memory alloy in order to further improve the performance of the material.

ferromagnetic shape memory alloy

Compared with the traditional temperature controlled shape memory alloy, the ferromagnetic shape memory alloy has larger output strain and higher response frequency. This is because the energy propagates through the magnetic field during the service process and is not affected by the thermal conductivity and heat dissipation conditions of the alloy material. Its shape memory effect is to stimulate the preferred reorientation between twin martensite variants through the external magnetic field The macro shape deformation of the alloy occurs. Ferromagnetic shape memory alloy can not only provide the same specific power as traditional memory alloy, but also transmit at a higher frequency. However, in general, ferromagnetic shape memory alloy will encounter similar design problems with traditional memory alloy in the application process. In addition, the hardness of ferromagnetic shape memory alloy is very large and brittle, so it can only be processed and operated at low temperature. Therefore, it is difficult to shape and shape ferromagnetic shape memory alloy, and it is not suitable for high temperature and high strength environment at present. Therefore, it is still necessary to further study the existing ferromagnetic shape memory alloy in order to further improve the performance of the material.

Shape memory film material

Due to the application of shape memory alloy materials in mechanical systems, especially in micro actuators, shape memory alloy films have been widely studied. Shape memory thin film materials are generally used as independent thin films to become micro actuators. In the rapid development of MEMS, NiTi thin film has become the first choice on the micro level

The actuator, due to its excellent shape memory performance and high frequency, can still maintain a large output power. It is expected that the micro NiTi drivers based on sputtered NiTi films will occupy a large part of the commercial market, especially for medical micro devices and implantable applications. However, the application of shape memory thin film materials in some fields with ambient temperature higher than 100 ℃ is limited, such as automobile engine, fire alarm and aviation turbine, so in recent years, the research on high temperature shape memory thin film materials with phase change temperature higher than 100 ℃ has been increased.

Development trend of shape memory alloy

(1) To develop new or improve the existing shape memory materials, for example, to add appropriate third alloying elements into the shape memory alloy system, improve its martensitic transformation, and achieve fine control of its transformation process at the micro level.

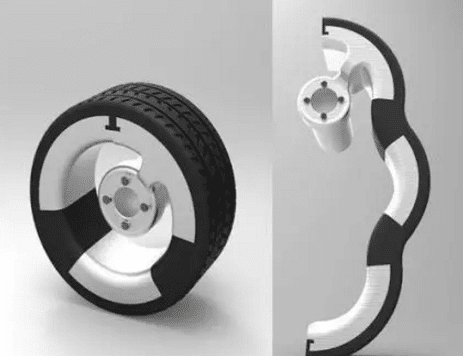

(2) Shape memory alloy with excellent functional properties can be compounded with other materials with good structural properties to meet the requirements of special field applications.

(3) In order to meet the demand of commercial application, we should increase its commercial application and improve the preparation method for large-scale production.