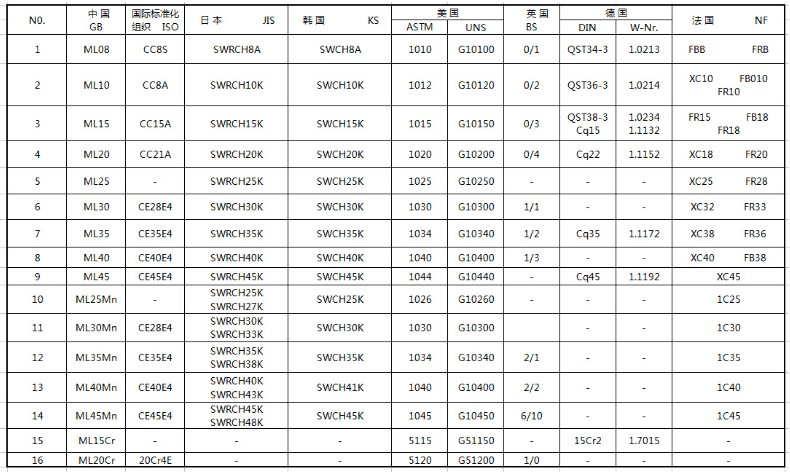

Cold heading quality steel is a highly interchangeable steel for standard part made of cold plastics using the plasticity of metal. Cold heading quality steel products are widely used in the manufacture of bolts, nuts and other fasteners for the manufacture of cold extrusion parts and various cold-formed parts. With the development of the automotive industry, cold forged steel is gradually applied to electrical appliances, cameras, textile equipment, machinery manufacturing and other fields.

Cold heading quality steel technical requirements and main process

1.cold heading quality steel technical requirements

Cold heading quality steel wire rods are generally low, medium carbon quality carbon structural steel and alloy structural steel. Standard parts have strict requirements on the dimensional accuracy of raw materials. The specifications of hot-rolled steel are limited, and the dimensional accuracy is also difficult to meet the requirements. Therefore, almost all of the standard parts are made of cold-drawn steel wire. The qualified cold heading quality steel wire must meet the following requirements.

(1) Requirements for chemical composition: Elements such as O, P, and S have a decisive influence on the form, quantity, and size of steel, so it is required to control its content; for alloy steel, elements such as silicon, aluminum, and manganese are controlled in a small amount. It is advisable to avoid causing crack of cold heading.

(2) Surface quality: The standard parts factory statistics show that 80% of cold cracking is caused by surface defects of steel wire, such as horizontal stripes, scratches, and micro cracks. Therefore, the surface quality of the wire is very strict, the dimensional tolerance is ± 0.20mm, and the depth of crack and scratch is less than 0.07mm.

(3) Decarburization: Surface decarburization causes a significant drop in bolt surface strength and fatigue life.

(4) Non-metallic impurities: high content of non-metallic impurities in steel is an important cause of cold cracking of standard parts, especially the brittle impurities of type B and D in non-metallic impurities. The closer to the surface of the steel wire, the greater the harm, so It is required that the Class B impurity should be no more than 15μm within 2mm from the surface layer.

(5) Metallographic structure: The metallographic structure of cold heading quality steel is ferrite and granular pearlite. The grain size and distribution of the pearlite are also factors influencing the cold heading performance. The ideal organization is that the pearlite grains are similar in size and evenly distributed on the ferrite matrix. The order of cold and cold performance of different microstructures of pearlite is from granular pearlite, sorbite, fine pearlite and flaky pearlite.

(6) Low-magnification structure: The macroscopic structure of cold-rolled steel should not have defects such as shrinkage, delamination, white spots, cracks, pores, central porosity, and central carbonation.

(7) Grain size: cold heading quality The internal structure of the wire is different from other steel wires, and the grain size is not as fine as possible. The grain size is too fine, and the tensile strength and the yield strength increase to increase the deformation resistance, which is disadvantageous for cold heading.

(8) Cold heading performance: Good cold heading performance means that the steel wire has low deformation resistance and can withstand a large degree of deformation without cracking. It is generally considered that the reduction of the area and the yield ratio are relatively reliable. The reduction ratio of the section of the alloy steel should be not less than 50%. The cold-twisted steel wire has a small yield ratio, and the cold heading performance is relatively good. The yield ratio of the alloy steel should be no more than 0.70.

2.cold heading quality steel main production process

The key to smelting cold heading quality steel is to improve the purity of molten steel and reduce the non-metallic impurities content of molten steel. Stabilizing the carbon content of the molten steel end point within the specified range is the main measure to reduce the degree of oxidation of molten steel and reduce non-metallic impurities in molten steel.

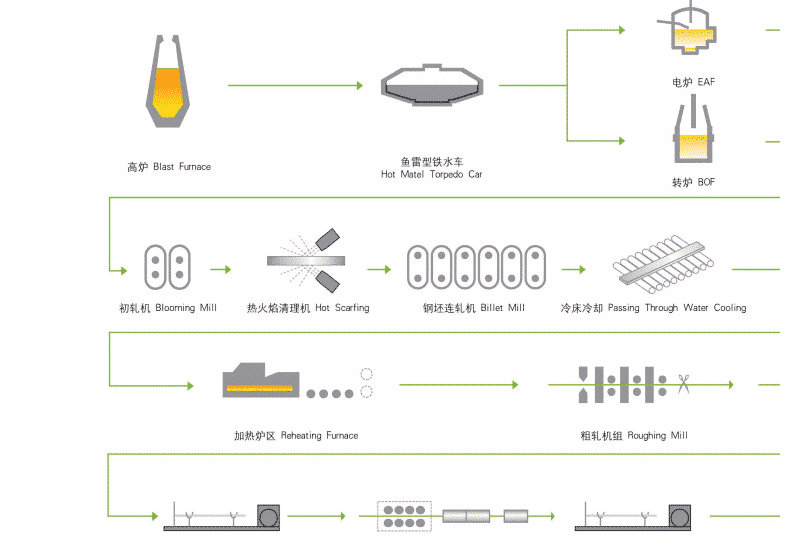

Process of production of wire rod made from cold heading quality steel:

Hot metal → converter → refining furnace → continuous casting → heating → high speed wire rolling → high line controlled cooling → finished product inspection → storage.

Cold heading quality steel wire production process is basically the same as carbon steel wire, but cold heading quality steel has high deformation resistance. In order to ensure cold heading, spheroidizing annealing is indispensable and an ideal tissue can be obtained.

Common process routes:

Wire → cold drawing → spheroidizing annealing,

Wire → recrystallization annealing → cold drawing → spheroidizing annealing.

Requirements for the smelting process:

(1) The tapping temperature is 1630-1660 ° C;

(2) Deoxidation alloying, final deoxidation addition of silicon aluminum calcium strontium alloy;

(3) The ladle is cleaned without cold steel, and the ladle is blown with argon.

Main factors affecting the quality of cold heading quality steel

In general, the factors affecting the quality of cold heading quality steel are material plasticity, material matrix continuity, material structure continuity and material surface quality. According to the quality inspection of cold heading quality steel, it is found that the factors affecting the quality of cold heading quality steel mainly include the following four aspects: chemical composition of steel, surface defects of the blank, equipment adjustment, grain size and rolling process parameters.

1. The influence of chemical composition: sulfur, phosphorus and other impurity elements in steel directly affect the cold heading performance of cold heading quality steel. In the smelting process of cold heading quality steel, the corresponding impurities should be removed for different steel grades. Some non-metallic impurities destroy the continuity of the steel matrix, and under the action of static load and dynamic load, it often becomes the starting point of cold heading quality steel crack. Therefore, non-metallic impurities in steel should be minimized and treated (such as calcification) to reduce their damage in steel.

2. Influence of surface defects of the blank: The surface defect of the blank is the source of cracks that cause cold heading cracking. The main forms include heavy skin on the surface of the blank, cracks, sharp excess and so on. During processing, stress concentration occurs due to the presence of cracks, and complex stress states are generated, resulting in crack expansion and finally cold heading cracking. Therefore, the selection of high-quality steel billets is a prerequisite for improving the quality of cold heading quality steel. The presence of severe temperature inhomogeneities during the rolling process also causes cracking of the product.

3. The effect of equipment adjustment on the performance of cold heading quality steel during the rolling process: the formulation of various rolling schedules in the production process is the main factor affecting the cold heading performance of the product, such as the reduction of the amount of pressing, tension, etc. Assembly and adjustment. If the rolling production is improperly adjusted, the product will produce surface cross lines or scratches during the rolling process, destroying the surface of the product and forming a cracking crack source. Therefore, the development of reasonable rolling procedures is the key to improving the quality of cold heading quality steel.

4. Effect of grain size: Grain size is one of the criteria for measuring whether or not cold heading quality steel can achieve a certain comprehensive performance. The finer the crystal grains, the smaller the chance of cracking due to stress concentration inside, which is advantageous for the performance of cold heading and the like. Fine-grain steel can withstand large deformation, has large elongation, reduction in area, good plasticity and high toughness and strength. Therefore, it is required that the austenitizing temperature should not be too high during the rolling process, and the holding time should not be too long.

5. The influence of rolling process parameters. The cold heading quality steel is organized into ferrite and pearlite. The key to controlling the cold is to decompose the austenite at a moderate temperature and to make the decomposition transition longer, so as to obtain moderate ferrite grains and a small amount. The pearlite improves the strength of cold heading quality steel and does not decrease the plasticity index, and obtains better comprehensive mechanical properties. 13 ~ 15m / min) and the coiling temperature, so that the final product performance meets the requirements, in line with the relationship between the basic composition of iron and carbon and mechanical properties.

Main measures to improve the quality of cold heading quality steel

The biggest problem in the production of cold heading quality steel is how to solve the cracking of the steamed bread during the actual cold heading process. For the technical requirements of cold heading quality steel, combined with the factors affecting the performance of cold heading quality steel and the actual production, the following measures should be taken in the production of cold heading quality steel:

1. Strictly control the chemical composition of steel according to the standard of cold heading quality steel, optimize the material structure, improve the plasticity of the material, ensure the stability of steel performance, reduce the damage of impurities to performance, and reduce the content of harmful elements in steel.

2. Through the control of smelting and rolling process, reduce the amount of reduction, rolling pass and number of times of turning, to obtain uniform and fine grain structure, avoid wrinkles during production and surface cross lines generated by the ear. Improve the comprehensive mechanical properties of cold heading quality steel.

3. Select the appropriate roll and uniform deformation hole type system to ensure the smooth surface of the product, reduce the crack of the finished product, improve the quality of production spare parts, and ensure the process requirements.

4. Strictly control the heating temperature, time and furnace atmosphere, maintain positive pressure operation, reduce surface burning and surface decarburization.

5. Strengthen the inspection of the billet and the quality inspection before the furnace, strictly control the surface quality of the billet, and use the billet of the large section as much as possible to increase the total deformation from the billet to the material.