Maybe you’ve heard people?should never ever drill a hole with an end mill if there isn’t already a hole at the center for the chips to clear. Why can’t the ??? clear the chips? If the answer is no.?How can you?plunge with an end mill?to produce a pocket as done by drill bit?

?? ??? ?? ?? ?? ???? ??????

As the subtitle indicates, the two kinds of tools are significantly different. Firstly, they vary in tool geometry. End mill’s cutting part is wrapped around flutes, which are a bunch of helical grooves on side of ???s. Each flute is with a sharp edge at least. While you can’t see this kind of component on drill bits cause they merely use the edges on its top area instead of lateral cutting edge to drill down and evacuate chips. Secondly,?End mill is more versatile than drill bit. End mills are devised for not only cutting?horizontally?on work piece but also primarily making a groove then broaching the whole hole based on the groove afterwards. Whereas drill bits’?can be only applied for boring straight hole down to material. In a word, drill bit can’t be replaced with end mill to accomplish milling operation. ?

?? ??? ???? ?? ? ?? ??? ??????

??? 1.5mm ??? ??? ??? ??? ??????. 1.5mm ??? ?? ?? ??? ?? ? ??? ???? ???? ?? ? ? ????.

If you need to drill a very deep hole – more than 4 times your hole diameter, choose a drill. Because if the hole diameter exceeds this value, it may be very difficult for the end milling cutter to remove the chips, which will quickly wear your tool and your workpiece.

???? ??? ?? ??? ??????? ??? ?? ? ? ????. ???? ?? ???? ?? ?? ???? ?? ?? ????.

?? ??? ??? ???????? ??? ????? ???? ????? ??? ??? ??? ???? ???? ??? ??? ?????.

?? ?? ?? ????????

? ??? ?????? ? ???? ? ??? ? ??? ?????. ?? ?? ??? ????????. ??? ??? 60-80% ? ?? ??? ???? ??? ?? ?? ??? ??? ????? ??? ??? ? ????.

Need to level the bottom hole on the workpiece? Ordinary drills can’t do this, so you’d better erase this item from the drill’s work list.

??? ??? ??? ?? ???????? ?? ?? ??? ??? ?? ? ??? ?? ?? ??? ??????.

??? ?? ??? ?? ??? ???????.

? ??? ??? ?? ?? ??? ?? ?? ? ?? ?? ? ??? ??????. ?? ?? ? ?? ??? ?? ?? ? ?? ???? ?? ????. ?? ??? ??? ???? ??? ?? ?? ?? ??? ??? ????. ?? ?? ?? ???? ??? ???? ?? ?? ?? ? ??? ??? ??? ???? ?? ?? ????. ??? ????? ??? ?? ?? ?? ?? ???, ??? ???? ???? ?? ? ??? ?? ????? ?? ?? ??? ????. ??? ? 1/8 ?? ??? ?? ??? ??? ??? ? 1/2 ?? ??? ?????. ??? ?? ?? ?? ??? ????. ?????? ??? ?????.

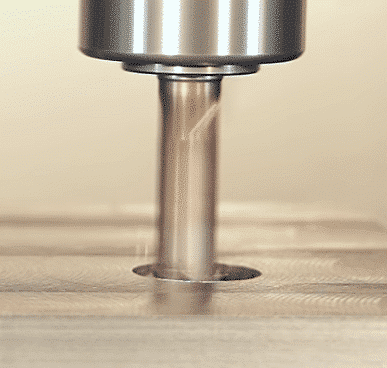

They leave a very nice finish on the inside of the hole. You will have to go slower than a drill, but there’s no problem evacuating the chips. Mostly, it’s done when you want a flat bottom hole such as a counterbore. As far as depth of plunge, about half the tool diameter is standard. Sometimes more or less to end up with the least amount of passes to achieve final depth.

??, ?? ??? ?? ?? ?? ?? ? ????. ?? ?? ?? ??? ?? ?? ????, ?? ?? ?? ??? ?? ??? ? ???? ?? ?? ??? ????.