Type 1: cutting tap

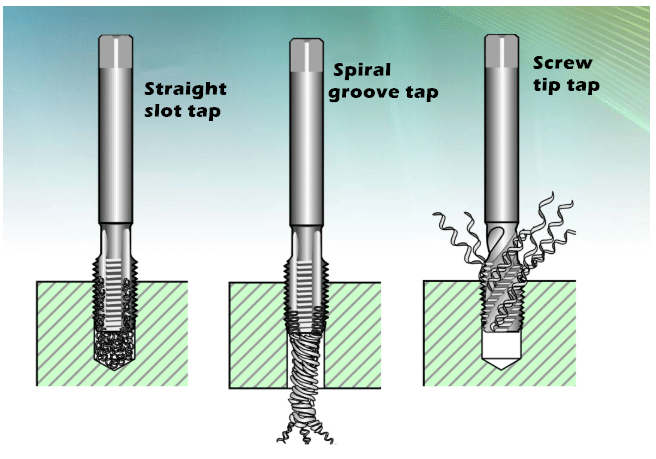

1. Straight slot tap: for through hole and blind hole processing, iron chips exist in tap groove, processing thread quality is not high, more often used for short chip material processing, such as gray iron, etc;

2. Spiral groove tap: used for blind hole processing with hole depth less than or equal to 3D. Iron chips are discharged along the spiral groove, and the thread surface quality is high;

The screw tap with 10 ~ 20 ° helix angle can process the thread depth less than or equal to 2D;

The screw tap with 28 ~ 40 ° helix angle can process thread depth less than or equal to 3D;

The 50 ° spiral angle tap can process thread depth less than or equal to 3.5D (special condition 4D);

In some cases (hard material, large pitch, etc.), in order to obtain better tooth tip strength, spiral groove tap will be selected to process through hole;

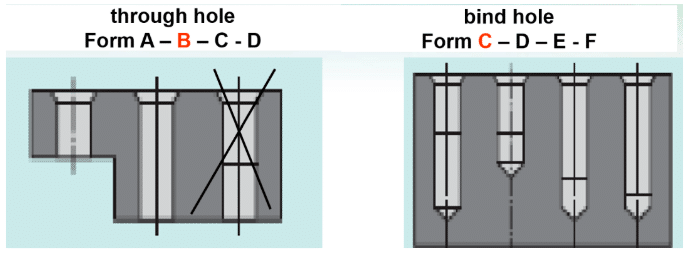

3. Screw tip tap: usually only used for through-hole, the length diameter ratio can reach 3d ~ 3.5D, the iron chips are discharged downward, the cutting torque is small, and the surface quality of the processed thread is high, also known as edge angle tap or tip tap;

When cutting, it is necessary to ensure that all the cutting parts are penetrated, otherwise the teeth will collapse;

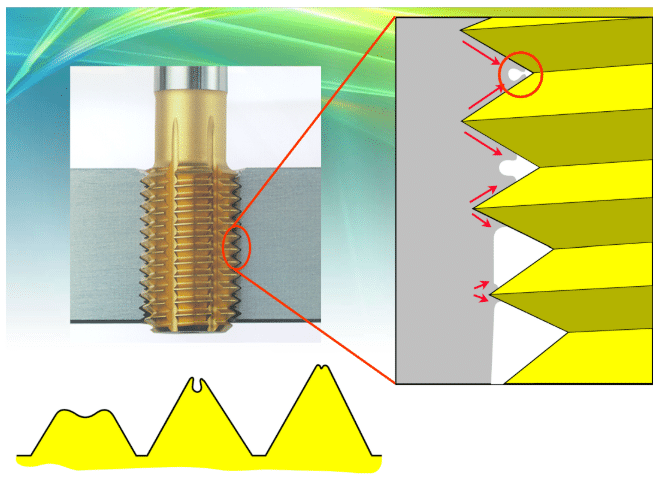

Type 2: extrusion tap

It can be used to process through hole and blind hole. It can only be used to process plastic materials;

Its main characteristics are as follows

1. Machining thread by plastic deformation of workpiece;

2. The tap has large cross-sectional area, high strength and is not easy to break;

3. The cutting speed is higher than that of the cutting tap, and the productivity is also improved accordingly;

4. Due to the cold extrusion processing, the mechanical properties of the thread surface are improved, the surface roughness is high, and the thread strength, wear resistance and corrosion resistance are improved;

5. No chip processing

The disadvantages are as follows:

1. It can only be used for processing plastic materials;

2. High manufacturing cost;

There are two types of structures:

1. Extrusion tap without oil groove – only used for blind hole vertical heater;

2. Extrusion tap with oil groove – suitable for all working conditions, but oil groove is not designed for small diameter taps due to manufacturing difficulty;

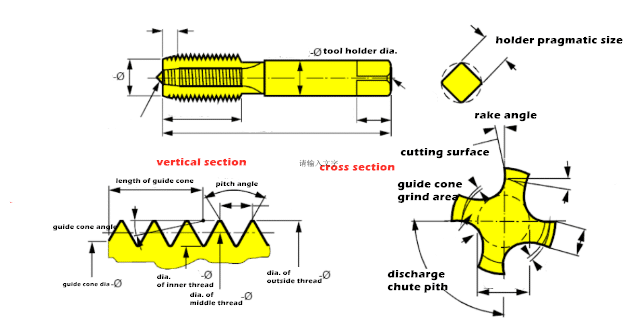

Structural parameters of taps

external dimension

Total length: attention should be paid to some working conditions requiring special lengthening

Slot length: through

Type of handle: at present, the common standard of handle side includes DIN (371 / 374 / 376), ANSI, JIS, ISO, etc., and the matching relationship with the handle of tapping tool should be paid attention to when selecting;

thread part

Precision: to be selected according to the specific thread standard. The ISO 1 / 2 / 3 grade of metric thread is equivalent to the national standard H1 / 2 / 3, but the manufacturer’s internal control standard should be paid attention to;

Cutting tap: the cutting part of the tap has formed a fixed mode. Generally, the longer the cutting cone is, the better the tap life is;

Correction teeth: play an auxiliary and correction role, especially in the unstable working conditions of tapping system, the more correction teeth, the greater the tapping resistance;

chip removal slot

Groove type: it affects the forming and discharging of scrap iron, which is usually the internal secret of each manufacturer;

Front angle and back angle: when the tap becomes sharper, the cutting resistance can be obviously reduced, but the strength and stability of the tooth tip decrease, and the back angle is the back angle of relief grinding;

Groove number: the increase of groove number and cutting edge number can effectively improve the tap life, but it will compress the chip removal space, which is disadvantageous to chip removal;

Material of tap

1. Tool steel: it is mostly used for hand used incisor tap, which is not common at present;

2. Cobalt free high speed steel: at present, it is widely used as tap material, such as M2 (W6Mo5Cr4V2, 6542), m3, etc., and the mark code is HSS;

3. Cobalt bearing high speed steel: Currently, it is widely used as tap material, such as M35, M42, etc., and its mark code is hss-e;

4. Powder metallurgy high speed steel: used as high-performance tap material, the performance is greatly improved compared with the above two, and the naming methods of different manufacturers are also different, and the marking code is hss-e-pm;

5. Cemented carbide materials: usually select ultra-fine particles, good toughness, mainly used for manufacturing straight slot taps, processing short chip materials, such as gray cast iron, high silicon aluminum, etc;

Taps are highly dependent on materials. Selecting good materials can further optimize the structural parameters of taps to make them suitable for high efficiency and more severe working conditions, and at the same time, have a longer life. At present, large tap manufacturers have their own material factories or material formulations. Meanwhile, due to the problems of cobalt resources and price, new cobalt free high-performance high-speed steel has also come out.

Coating of taps

1. Steam oxidation: the tap is put into the high temperature steam to form an oxide film on its surface, which has good adsorption to the coolant, can reduce friction, and prevent the adhesion between the tap and the material to be cut, which is suitable for processing soft steel;

2. Nitriding treatment: tap surface nitriding, forming a surface hardening layer, suitable for processing cast iron, cast aluminum and other materials with large tool wear;

3. Steam + nitriding: the combination of the above two points;

4. Tin: golden yellow coating, with good coating hardness and lubricity, and good adhesion performance, suitable for processing most materials;

5. TiCN: blue gray coating with hardness of 3000hv and heat resistance of 400 ° C;

6. Tin + TiCN: dark yellow coating with excellent hardness and lubricity, suitable for processing most materials;

7. TiAlN: blue gray coating, hardness 3300hv, heat resistance up to 900 ° C, can be used for high-speed machining;

8. CrN: silver gray coating, excellent lubrication performance, mainly used for processing non-ferrous metals;

The influence of tap coating on tap performance is very obvious, but at present, most of the special coatings are researched by manufacturers and coating manufacturers alone, such as LMT IQ, Walter THL, etc.

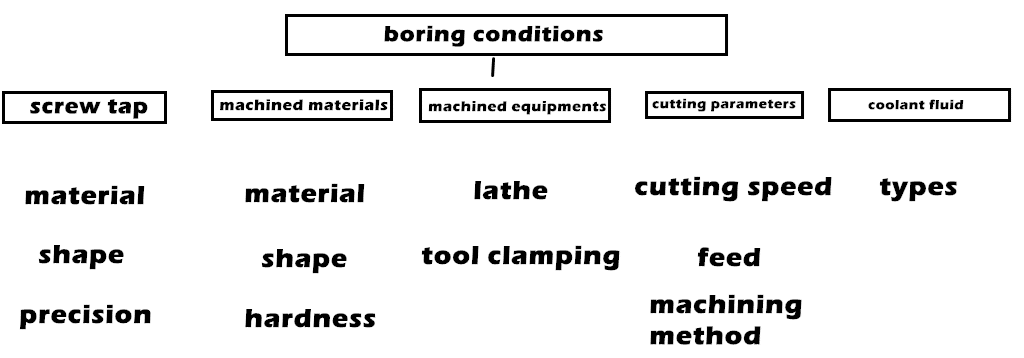

Factors affecting tapping

tapping equipment

1. Machine tool: can be divided into vertical and horizontal processing methods, for tapping, vertical processing is better than horizontal processing, horizontal processing external cooling should consider whether sufficient cooling;

2. Tapping toolholder: it is recommended to use special tapping toolholder for tapping. Synchronous tapping toolholder with good rigidity and stability is preferred, and flexible tapping toolholder with axial / radial compensation shall be selected as far as possible. Except for small diameter taps (< M8), square body drive should be used as far as possible;

3. Cooling conditions: for tapping, especially for extrusion Taps, the requirement for coolant is lubrication > cooling; the actual use can be adjusted according to the conditions of the machine tool (when using emulsion, the recommended concentration is more than 10%);

machined parts

1. Material and hardness of the workpiece to be processed: the hardness of the workpiece material should be uniform, and it is generally not recommended to use a tap to process parts exceeding hrc42;

2. Tapping bottom hole: structure of bottom hole, selection of suitable drill bit; dimension accuracy of bottom hole; quality of bottom hole wall;

Processing parameters

1. Rotation speed: the basis of speed setting is the type of tap, material, processed material and hardness, and the advantages and disadvantages of tapping equipment;

Generally, the selection is based on the parameters given by the tap manufacturer, and the speed must be reduced under the following conditions:

-The results show that the rigidity of the machine tool is poor, the tap runout is large, and the cooling is not enough;

-Uneven material or hardness in tapping area, such as solder joint;

-The tap is lengthened or an extension rod is used;

-Wojia, external cooling;

-Manual operation, such as bench drill, rocker drill, etc;

2. Feed: rigid tapping, feed = 1 pitch / revolution

Under the condition of flexible tapping and sufficient compensation variable of toolholder:

Feed = (0.95-0.98) pitches / revolution

Tips on selection of taps

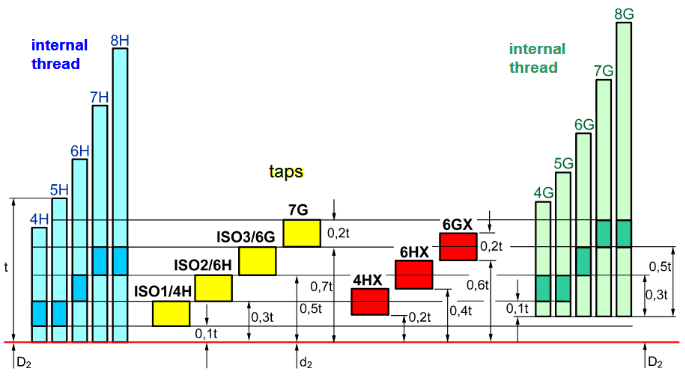

Tolerance of taps with different Accuracy grades

Selection basis

it is not only based on the accuracy grade of the thread to be processed to select and determine the accuracy grade of the tap

The material and hardness of the workpiece to be processed;

Tapping equipment (such as machine condition, clamping tool handle, cooling environment, etc.);

The accuracy and manufacturing error of taps;

For example, when processing 6h thread on steel parts, 6h precision tap can be selected; when processing gray cast iron, due to the rapid wear of tap pitch diameter and small expansion of screw hole, it is appropriate to select 6hx precision tap, which will have better service life.

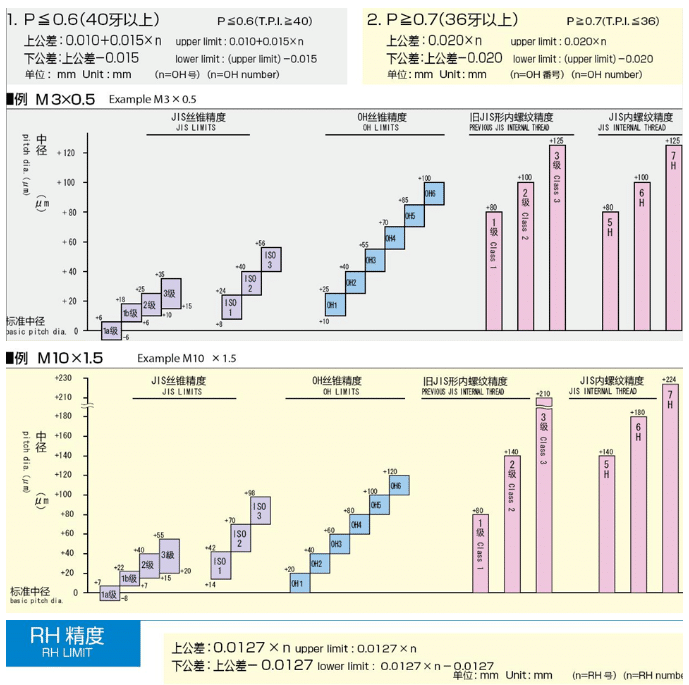

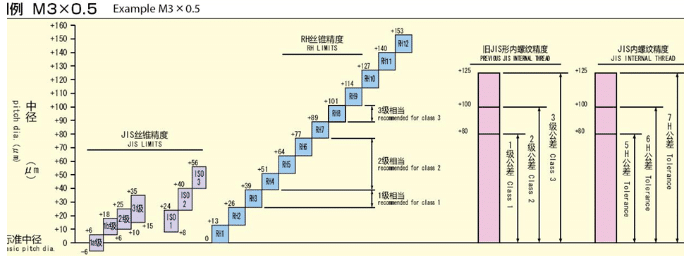

About the accuracy of Japanese taps:

Oh precision system is used for cutting tap OSG, which is different from ISO standard. The oh precision system forces the width of the entire tolerance zone from the lowest limit to 0.02mm as an accuracy grade, named oh1, oh2, oh3, etc;

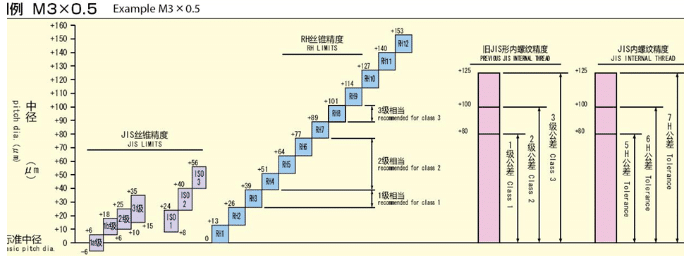

The extrusion tap OSG uses the RH precision system. The RH precision system forces the width of the entire tolerance zone from the lowest limit. Every 0.0127mm is regarded as an accuracy grade, named Rh1, Rh2, rh3, etc.

Therefore, when using ISO precision taps to replace Oh precision taps, we can not simply think that 6h is approximately equal to oh3 or OH4 level, which needs to be determined by conversion or according to the actual situation of customers.

Tap dimensions

1. DIN, ANSI, ISO, JIS, etc.

2. Allow to choose the appropriate total length, blade length and handle square size according to the customer’s different processing requirements or existing conditions;

Interference during machining![? ?? ? ?? ??? 11 ? ?? ? ?? ??? 10]()

Six basic elements of tap selection

1. Type of thread processing, metric, British, American, etc;

2. The type of thread bottom hole, through hole or blind hole;

3. Material and hardness of workpiece to be processed;

4. Depth of complete thread and bottom hole of workpiece;

5. The required accuracy of workpiece thread;

6. The shape standard of taps (special requirements need special marking).