Slow wire machine is a kind of high-precision machining machine, which can achieve machining accuracy of several μ m, and the surface roughness Ra can reach < 0.2 μ M. However, some mold factories do not pay attention to the details when using the slow wire machine, thinking that a good machine tool can easily achieve high-efficiency and high-precision machining. In fact, precision machining must establish the concept of precision machining!

process premise

Slow wire machine tools are equipped with process parameter library, and the process parameters are generally obtained by testing under specific conditions (such as workpiece material, electrode wire, temperature 20 ± 3 ℃, humidity 40-80%, etc.). If the following conditions change or fail to meet the requirements, the machining results may be deviated.

1. Flushing specification: when processing according to the standard parameters, the difference between the indicated value of the water pressure gauge and the theoretical value should be less than 0.5bar;

2. Clearance between workpiece and nozzle: 0.05 ~ 0.10 mm;

3. When the surface roughness is required to be RA ≥ 0.35 μ m, the efficiency oriented cutting wire can be selected (the same type of wire as the machine tool is recommended). When RA is less than 0.35 μ m, in order to obtain a good processing surface, the galvanized wire which pays attention to the surface should be selected for processing;

4. When finishing, please ensure that the water is less than 10, especially when finishing, please follow the process parameters. If necessary, replace the resin or purified water.

Influence of temperature on machining accuracy

In order to carry out high-precision and high-quality WEDM, the environment must be stable and meet the specified requirements. There should be no direct sunlight or air flow. The temperature change should be monitored. The temperature range to ensure the working accuracy of the machine tool is 20 ± 3 degrees. If the temperature difference is large, the machining accuracy and surface roughness will be affected.

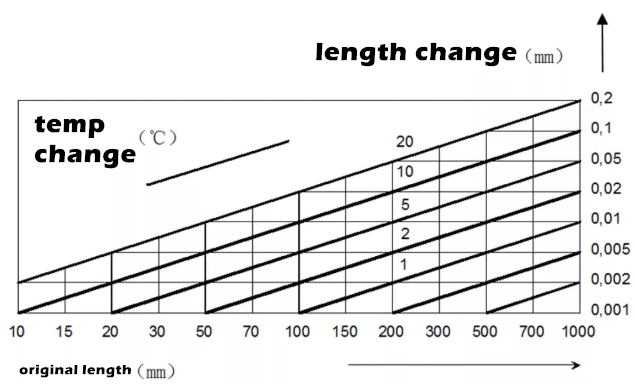

The change of room temperature has a great influence on the machining accuracy, which is reflected in the size, position and shape. As shown in the figure below, the greater the temperature change and the larger the workpiece size, the more obvious the influence of temperature. For example, a 200 mm long workpiece with a temperature difference of 5 degrees will produce a dimension error of 0.01 mm. It is better to finish a larger part in one start-up. If it is put on for one night, the main cutting has little effect, but if it is stopped during trimming, it is difficult to ensure the machining accuracy.

Influence of room temperature change on machining accuracy

The thermal characteristics of CNC machine tools have an important impact on the machining accuracy, accounting for more than half of the machining accuracy. There is a big difference between the machining accuracy of the machine tool in the long-term stop state and the thermal balance state. The reason is that the temperature of the spindle and each moving axis of the CNC machine tool is relatively maintained at a fixed level after running for a period of time, and with the change of processing time, the thermal accuracy of CNC machine tools tends to be stable, which shows that even high-precision machine tools have only one Stable machining accuracy can be obtained only under stable temperature environment and thermal balance state. It is the most basic knowledge of precision machining to preheat the machine tool. However, the warm-up movement of machine tools is ignored or unknown by many factories.

If the machine tool has been shelved for more than several days, it is recommended to preheat the machine tool for more than 30 minutes before high-precision machining; if the machine tool is in a state of only a few hours, it is recommended to preheat for 5-10 minutes before high-precision machining. The process of preheating is to let the machine tool participate in the repeated movement of the machining axis. It is better to carry out multi axis linkage. For example, let XYZ axis move from the lower left corner of the coordinate system to the upper right corner position, and repeatedly walk the diagonal line. When executing, you can write a macro program on the machine tool to let the machine repeatedly perform the warm-up action.

Factors affecting processing efficiency

There are many factors that affect the efficiency of WEDM. In case of inefficiency in processing, the following two factors can be considered.

(1) Limited by the part structure and clamping, it can not effectively flush high-pressure water

At this time, we can see whether the cutting parts can be improved from the clamping. Some parts are affected by the support fixture, the bottom surface is raised, some parts are affected by the position of the pressure plate and clamping screw, so they have to lift the upper nozzle, and some parts are afraid that the operator may touch the nozzle and fail to lower the upper nozzle. If the lower surface is raised, it depends on whether the fixture supporting surface is on the same plane as the worktable, or clamp the workpiece directly on the worktable.

Affected by the screw pressure plate and parts, see whether the jaw clamp can be used for clamping; if the operator is worried that the upper nozzle does not fall to the lowest position, a 0.1 mm feeler gauge can be prepared as required. For the parts that can not be effectively flushed with high-pressure water due to the structure limitation, the cutting energy can only be reduced. At this time, a correct understanding of the cutting efficiency is required.

(2)Silk transport system related (related to maintenance)

1) Check whether the cooling water of the conductive block is normal. In particular, whether there is cooling water for the lower conductive block, because copper dust will drop during cutting, which may block the cooling water of the lower conductive block or even flush water for processing the lower nozzle after long-term use of the machine tool. It should be cleaned and dredged;

2) The lower guide wheel on the lower arm rotates flexibly. Check and clean;

3) Whether the reeling wheel is normal;

- Check the tension and speed of the wire and readjust it if necessary;

- Check and clean the wire guide nozzle and conductive block.