As we all know, there are many kinds of bearing materials in the market. There are three kinds of common bearing materials: metal materials, porous metal materials, and non-metamaterials.

Metal Materials

Bearing alloys, bronze, aluminum-based alloys, zinc-based alloys, etc. are all metal materials. Among them, bearing alloys, also known as white alloys, are mainly alloys of lead, tin, antimony or other metals, which have low strength under heavy load and high-speed conditions. The reason is because of its characteristics, such as good wear resistance, high plasticity, good running-in performance, good thermal conductivity, good glue resistance and good adsorption with oil. However, because of its high price, it must be poured on bronze, steel strip or cast iron bearing bush to form a thinner coating

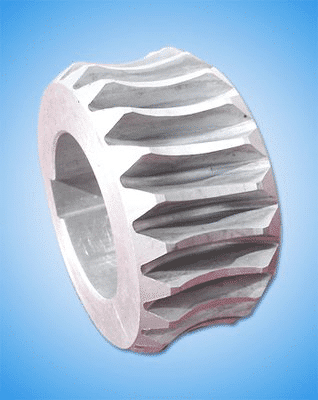

Bearing alloy

Bearing alloys are tin, lead, antimony and copper alloys. They are based on tin or lead and contain hard grains of antimony-tin (Sb-Sn) and copper-tin (Cu-Sn). Hard grains play an anti-wear role, while soft substrates increase the plasticity of materials. The elastic modulus and elastic limit of bearing alloy are very low. Among all bearing materials, it has the best Embeddedness and friction compliance. It is easy to run in with the journal, and it is not easy to bite with the journal. But the strength of bearing alloy is very low. It can not be made separately. It can only be attached to bronze, steel or cast iron bearing bushes for bearing lining. Bearing alloys are suitable for heavy-duty, medium and high-speed applications, and the price is relatively expensive.

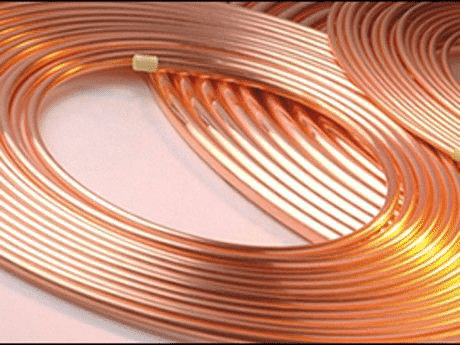

copper alloy

Copper alloys have higher strength, better friction reduction and wear resistance. Bronze has better properties than brass and is the most commonly used material. There are several kinds of bronze, such as tin bronze, lead bronze, and aluminum bronze. Among them, tin bronze has the best antifriction property and is widely used. However, tin bronze has higher hardness than bearing alloys, poor wearability, and embeddedness, and is suitable for heavy and medium speed applications. Lead bronze has strong adhesion resistance and is suitable for high-speed and heavy-duty bearings. Aluminum bronze has high strength and hardness and poor adhesion resistance. It is suitable for low-speed and heavy-duty bearings.

Aluminum-based alloy

Aluminum-based bearing alloys have good corrosion resistance, high fatigue strength, and good friction properties. These qualities make Al-based alloys replace more expensive bearing alloys and bronze in some areas. Aluminum-based alloy can be made into single metal parts (such as bushes, bearings, etc.) or bimetal parts. Aluminum-based alloy is used as bearing lining and steel is used as backing for bimetal bearing bushes. A kind o

Grey cast iron and wear-resistant cast iron

Ordinary gray iron or wear-resistant gray iron with nickel, chromium and titanium alloys, or ductile iron, can be used as bearing materials. The flake or spherical graphite in this kind of material can form a lubricating graphite layer after it is covered on the surface of the material, so it has a certain antifriction and wear resistance. In addition, graphite can absorb hydrocarbons and improve boundary lubrication performance. Therefore, when gray cast iron is used as bearing material, lubricating oil should be added. Because of its brittleness and poor running-in, cast iron is only suitable for low-speed and light-load situations without impact load.

Nonmetallic Materials

The most widely used non-metallic materials are various plastics (polymer materials), such as phenolic resin, nylon, polytetrafluoroethylene and so on. The characteristics of polymer are: it does not react with many chemicals, and has strong corrosion resistance; it has certain self-lubrication, can work under non-lubrication conditions, and has certain lubrication ability under high-temperature conditions; good embeddedness; good antifriction and wear resistance.

When choosing polymer as bearing material, we must pay attention to the following problems: because the thermal conductivity of polymer is only a few percents of that of steel, the dissipation of friction heat must be considered, which strictly limits the working speed and pressure value of polymer bearing. Because the linear expansion coefficient of polymer is much larger than that of steel, the clearance between polymer bearing and steel journal should be larger than that of the metal bearing. In addition, the strength and yield limit of polymer materials are low, so they can bear limited loads in assembly and operation. Because of the creep phenomenon of polymer materials at room temperature, it is not suitable to make bearings with strict clearance requirements.

Carbon-graphite can be used as bearing material in a bad environment. The more graphite content is, the softer the material is and the smaller the friction coefficient is. Metals, polytetrafluoroethylene or molybdenum disulfide can be added to carbon-graphite materials, and liquid lubricants can also be impregnated. Carbon-graphite bearings have self-wettability, and their self-wettability and friction reduction depend on the amount of water vapor adsorbed. Carbon-graphite has an affinity with lubricants containing hydrocarbons. Adding lubricants can improve boundary lubrication performance. In addition, it can also be used as bearing material for water lubrication.

Rubber is mainly used in areas where water is used as a lubricant and the environment is dirty.

Wood has a porous structure and can be improved by filler. Filling polymer can improve dimensional stability, reduce moisture absorption and increase the strength of wood. Bearings made of wood can work under dusty conditions.

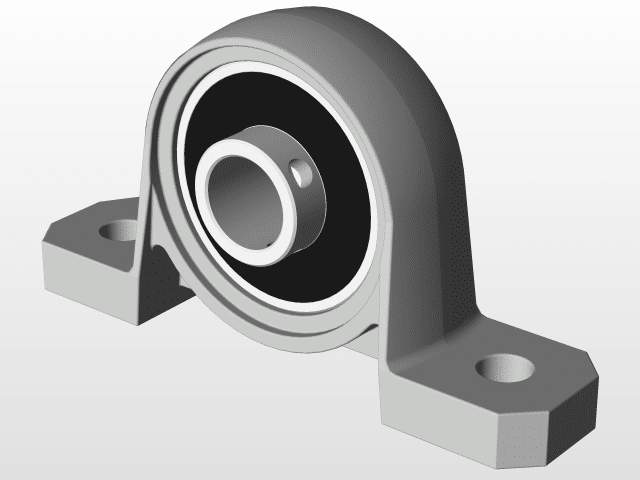

Porous Metal Materials

This is a bearing material made by pressing and sintering different metal powders. This material is a porous structure, and the voids account for about 10% to 35% of the volume. Before use, the bearing bush is soaked in hot oil for several hours to fill the hole with lubricating oil, so the bearing made of this material is usually called oil-bearing.

It has a self-lubrication. When working, because of the suction effect of journal rotation and the expansion effect of oil during bearing heating, oil will enter the friction surface to lubricate; when not working, because of capillary action, oil will be sucked back into the bearing, so it can work well even without lubricating oil for a long time. If the oil is supplied regularly, the effect is better. However, due to its low toughness, it is suitable for the case of smooth impact-free load and medium-low speed. Porous iron and porous bronze are commonly used. Porous iron is often used to make mill bushing, machine tool oil pump bushing, internal combustion engine camshaft bushing, etc. many

Porous bronze is often used to make bearings of the phonograph, electric fan, textile machinery, and automobile generator. There are already factories specializing in the manufacture of oil-bearing in our country, which can be selected according to the design manual when needed.

Powder metallurgy material is a kind of porous metal, which has a porous structure. If it is immersed in lubricating oil, the micro-pore is filled with lubricating oil and becomes an oil-bearing, which has self-lubricating property. Porous metal materials have low toughness and are only suitable for smooth impact-free loads and medium and small velocities.