Surface treatment is a process of forming an artificial surface layer on the surface of the base material, which is different from the mechanical, physical and chemical properties of the base material.

The purpose of surface treatment is to meet the requirements of corrosion resistance, wear resistance, decoration or other special functions of products. Our common surface treatment methods are mechanical grinding, chemical treatment, surface heat treatment, spraying surface. Surface treatment is to clean, clean, deburr, degrease, and remove oxide scale on the surface of the workpiece.

The common surface treatment processes are as follows:

Vacuum electroplating, electroplating process, anodizing, electropolishing, pad printing, galvanizing, powder spraying, water transfer printing, screen printing, electrophoresis, etc.

Surface treatment is a process of forming an artificial surface layer on the surface of the base material, which is different from the mechanical, physical and chemical properties of the base material.

The purpose of surface treatment is to meet the requirements of corrosion resistance, wear resistance, decoration or other special functions of products. Our common surface treatment methods are mechanical grinding, chemical treatment, surface heat treatment, spraying surface. Surface treatment is to clean, clean, deburr, degrease, and remove oxide scale on the surface of the workpiece.

The common surface treatment processes are as follows:

Vacuum electroplating, electroplating process, anodizing, electropolishing, pad printing, galvanizing, powder spraying, water transfer printing, screen printing, electrophoresis, etc.

01. Vacuum Metalizing

Vacuum electroplating is a physical deposition phenomenon. That is, argon gas is injected into the target in vacuum, and the target is separated into molecules, which are adsorbed by conductive goods to form a uniform and smooth metal like surface layer.

Applicable materials:

1. Many materials can be vacuum plated, including metals, hard and soft plastics, composites, ceramics and glass. The most common surface treatment is aluminum, followed by silver and copper.

2. Natural materials are not suitable for vacuum electroplating, because the moisture of natural materials will affect the vacuum environment.

Process cost: in the process of vacuum plating, the workpiece needs spraying, loading, unloading and re spraying, so the labor cost is quite high, but it also depends on the complexity and quantity of the workpiece.

Environmental impact: the environmental pollution of vacuum electroplating is very small, similar to the impact of spraying on the environment.

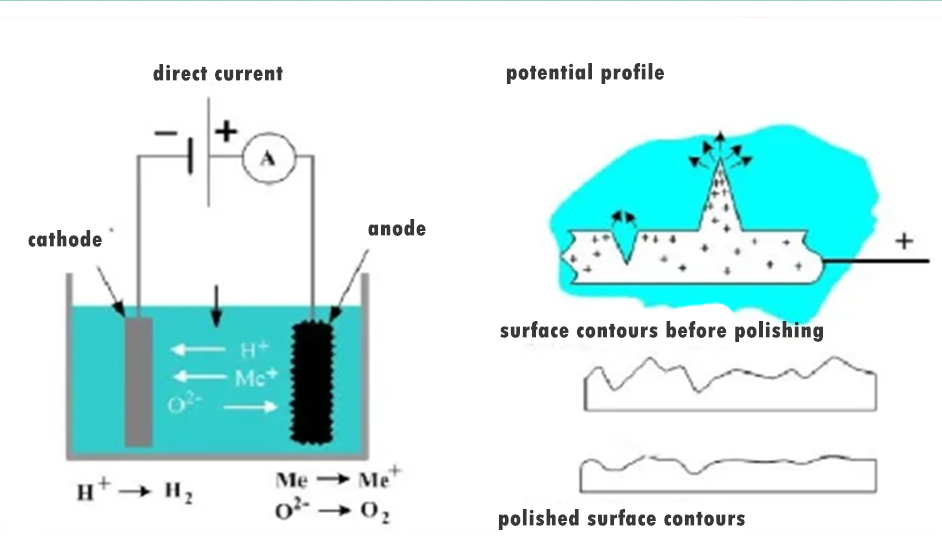

02. Electropolishing

Electropolishing is an electrochemical process in which the atoms of the workpiece immersed in electrolyte are converted into ions and removed from the surface due to the passage of current, so as to achieve the effect of removing fine burrs and increasing the brightness of the workpiece surface.

Applicable materials:

1. Most metals can be electropolished, especially for stainless steel (especially for Austenitic nuclear grade)

2. Different materials can not be electropolished at the same time, or even put in the same electrolytic solvent.

Process cost: the whole process of electropolishing is basically completed by automation, so the labor cost is very low.

Environmental impact: electropolishing uses less harmful chemicals. The whole process requires a small amount of water and is easy to operate. In addition, it can extend the properties of stainless steel and delay the corrosion of stainless steel.

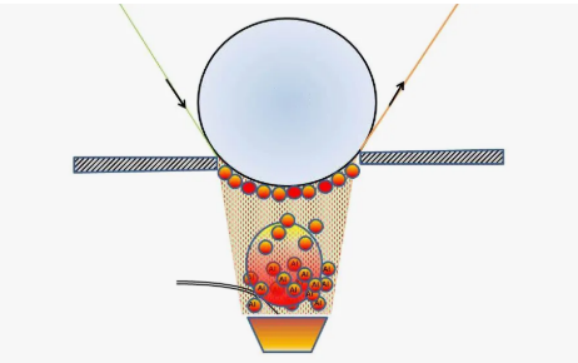

03.Pad Printing

It is becoming an important special printing technology to print words, graphics and images on the surface of irregular objects.

Applicable materials:

Almost all materials can use pad printing process, in addition to the soft material than silica gel pad, such as PTFE.

Process cost: low mold cost, low labor cost.

Environmental impact: because this process is only limited to soluble ink (which contains harmful chemicals), it has a great impact on the environment.

04. Galvanizing

It is a kind of surface treatment technology to coat a layer of zinc on the surface of iron and steel alloy materials for aesthetic and rust prevention. The zinc layer on the surface is a kind of electrochemical protection layer, which can prevent metal corrosion. The main methods used are hot-dip galvanizing and electro galvanizing.

Applicable materials:

As the galvanizing process depends on metallurgical bonding technology, it is only suitable for the surface treatment of steel and iron.

Process cost: no mold cost, short cycle / medium labor cost, because the surface quality of workpiece largely depends on the manual surface treatment before galvanizing.

Environmental impact: as the galvanizing process increases the service life of steel parts for 40-100 years, it can well prevent the rust and decay of the parts, so it has a positive effect on the protection of the environment. In addition, after the service life of the zinc plated workpiece is expired, it can be sent back to the galvanizing tank, and the reuse of liquid zinc will not produce chemical or physical waste.

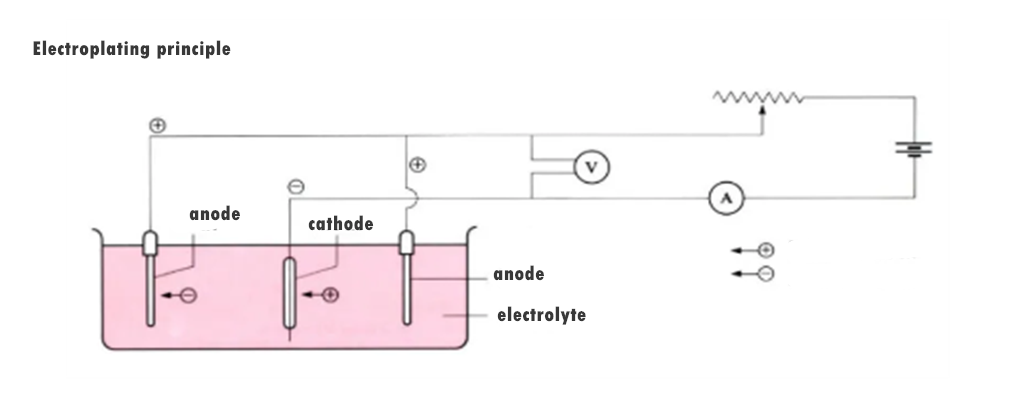

05.Electroplating

The process of using electrolysis to attach a layer of metal film on the surface of parts can prevent metal oxidation, improve wear resistance, conductivity, reflective property, corrosion resistance, and enhance beauty. The outer layer of many coins is also electroplated.

Applicable materials:

1. Most metals can be electroplated

But different metals have different levels of purity and plating efficiency. The most common are: tin, chromium, nickel, silver, gold and rhodium;

2. The most commonly used plastic for electroplating is ABS.

3. Nickel metal can not be used in electroplating products that contact skin, because nickel is irritating and toxic to skin.

Process cost: no mold cost, but need fixture to fix the parts / time cost depends on the temperature and metal type / labor cost (medium high), depending on the type of specific electroplating parts, such as silver and jewelry electroplating requires highly skilled workers to operate, because of its high requirements for appearance and durability

Environmental impact: a large number of toxic substances will be used in the electroplating process, so professional diversion and extraction are needed to ensure minimum environmental impact.

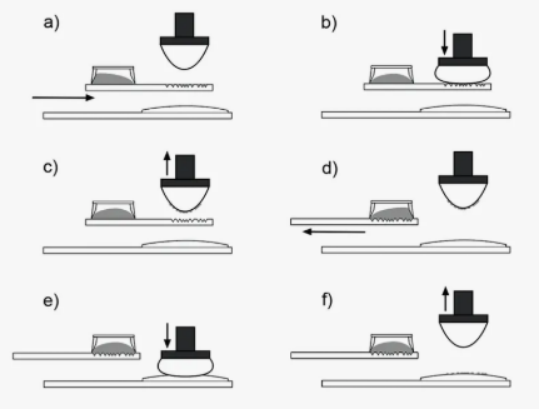

06.Hydro Transfer Printing

It is a way of printing the color patterns on the transfer paper on the surface of three-dimensional products by water pressure. With the improvement of people’s requirements for product packaging and surface decoration, water transfer printing is used more and more widely.

Applicable materials:

All hard materials are suitable for water transfer printing, suitable for spraying materials must also be suitable for water transfer printing. The most common are injection molded parts and metal parts.

Process cost: no mold cost, but need to use fixture to transfer multiple products at the same time, the time cost is generally not more than 10 minutes per cycle.

Environmental impact: compared with product spraying, water transfer printing uses printing coating more fully, reducing the possibility of waste leakage and material waste.

07.Screen Printing

Through the extrusion of the scraper, the ink is transferred to the substrate through the mesh of the graphic part, forming the same graphic as the original. Screen printing equipment is simple, easy to operate, printing, plate making simple and low cost, strong adaptability.

The common printing materials are: color oil painting, poster, business card, binding cover, commodity label, printing and dyeing textiles, etc.

Applicable materials:

Almost all materials can be screen printed, including paper, plastic, metal, ceramics and glass.

Process cost: mold cost is low, but still depends on the number of colors, because each color has to be a separate plate. Labor costs are high, especially when it comes to colorful printing.

Environmental impact: light color screen printing ink has little impact on the environment, but the ink containing PVC and formaldehyde has harmful chemicals, which need to be recycled and treated in time to prevent water pollution.

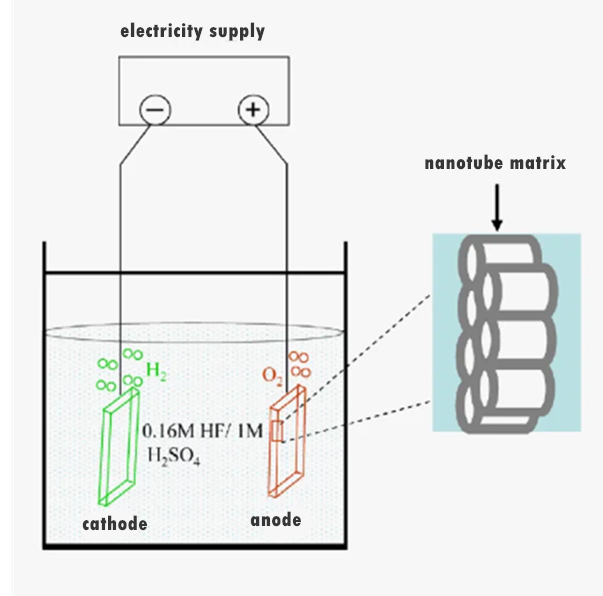

08. Anodic Oxidation

The main reason is the anodizing of aluminum. It is to produce a layer of Al2O3 (alumina) film on the surface of aluminum and aluminum alloy by electrochemical principle. This layer of oxide film has special characteristics such as protection, decoration, insulation and wear resistance

Applicable materials:

Aluminum products such as aluminum, aluminum alloy, etc

The determinate – the form and the object — the demonstrative pronoun this indefinite pronoun some question pronoun what

Process cost: in the production process, the consumption of water and electricity is quite large, especially in the oxidation process. The heat consumption of the machine itself needs to be cooled continuously with circulating water, and the power consumption per ton is usually about 1000 degrees.

Environmental impact: anodizing is not excellent in energy efficiency, and in aluminum electrolysis, anode effect will also produce gases that cause destructive side effects on the ozone layer of the atmosphere.

09.Metal Wired

It is a kind of surface treatment method to form lines on the surface of workpiece by grinding products, which plays a decorative effect. According to the different patterns after wire drawing, it can be divided into straight pattern wire drawing, random pattern wire drawing, ripple and spiral pattern

Applicable materials: almost all metal materials can use metal drawing process

Process cost: simple process, simple equipment, low material consumption, low cost and high economic benefit

Environmental impact: pure metal products, surface without paint and any chemical substances, 600 ℃ high temperature does not burn, does not produce toxic gases, compound fire protection requirements

10. In-Mold Decoration-IMD

It is a kind of forming method that put the printed pattern film into the metal mold, inject the resin for forming into the metal mold and join with the film, so that the printed pattern film and the resin form a whole and solidify into the finished product.

Applicable material: plastic surface

Process cost: only need to open a set of mold, can reduce the cost and man hour, high automation production, simplified manufacturing process, once injection molding method, forming and decoration at the same time.

Environmental impact: the technology is green and environmental protection, avoiding the pollution caused by traditional spray painting and electroplating