Precision CNC machining entails using computer programs to create pieces that are precisely sized. It employs a variety of techniques and materials. As a result, a thorough comprehension of the concept is required to assist you in getting the most out of your project.

This article will let you know what is precision machining, the precision machining process, the various machine tools used, their benefits, and their applications. If you need special precision-machined components, keep reading until the conclusion.

What exactly is precision machining?

High-precision machining technologies generate very precise and consistent products that meet exact specifications. There are no established tolerance parameters, however, that classify a product as a high-precision workpiece. The complexity of a certain tolerance is determined by part sizes and order volumes.

High-precision machining is a subtractive process, so the cutting tool removes material from the workpiece. This is in contrast to additive procedures like welding or casting. Using those procedures, the material can be added during manufacturing for identical sizes and shapes but varying densities.

What is the Precision Machining Process?

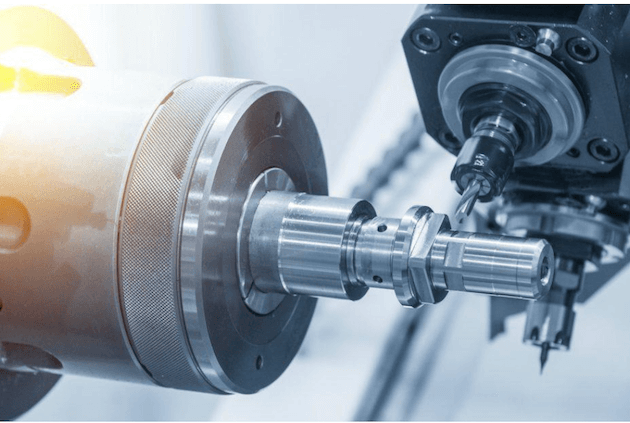

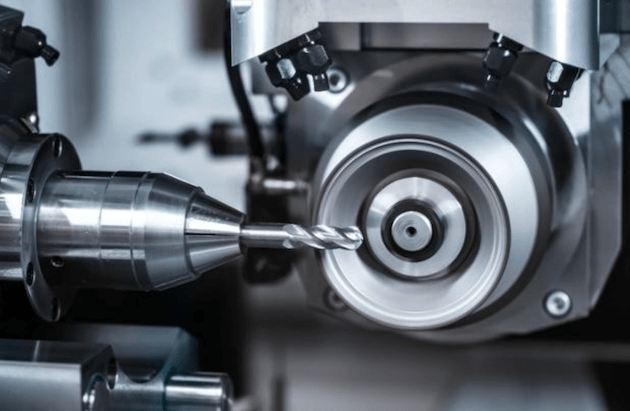

Precision machining begins with a big blank shape and works its way down to reveal the beautifully perfect form within (albeit with precision and digital tools nowadays). It all starts with a block of material. The raw material is sent into a turning or milling machine, and the material is deleted using a series of computer commands. Precision CNC (Computer Numerical Control) machining is another term for this.

Long before the material is transformed into a finished product, the design must be created, 3D computer models must be created, and model requirements must be entered into the computer program. Because all completed items must be homogeneous with the correct sizes and durability across the batch, proper engineering is crucial to this process.’

What are the materials used in precision machining?

Stainless steel is the undisputed monarch of materials used in many machining operations; its qualities make it the most extensively used material in many machining operations.

Of course, precise machining is not limited to the use of stainless steel. Materials including plastic, aluminum, ceramic, brass, bronze, copper, graphite, composites, titanium, tungsten, Kovar, Ni 200, Inconel, and Nitronic are commonly used in precision machining.

Applications for CNC Precision Machining

Precision machining is gaining popularity in the manufacturing industry because of its many applications, low cost, and quick turnaround times. Precision machining is employed in industries such as

Automobile Industry

Automobile manufacturers must build prototypes of new technologies to add to their current car versions before adding them to the manufacturing line. CNC precision machining is used to create prototypes to exact specifications. The technique also produces components for other modes of transportation, like cargo boats, transport vehicles, and others.

Medical Industry

The medical industry is continually expanding, and new equipment is required. They require large quantities of current equipment in addition to new ones. Precision CNC machining is needed to produce this equipment. Examples include orthotic devices, secure containers, implants, MRI machines, and research tools.

Defense and Military Industry

CNC has never been more important, with several nations developing their ideas for new munitions and defensive systems. All of these ideas are brought to life by the precision machining process, which employs a variety of materials and methods. Plane parts, transportation components, communication components, ammunition, and other items created for this business are examples.

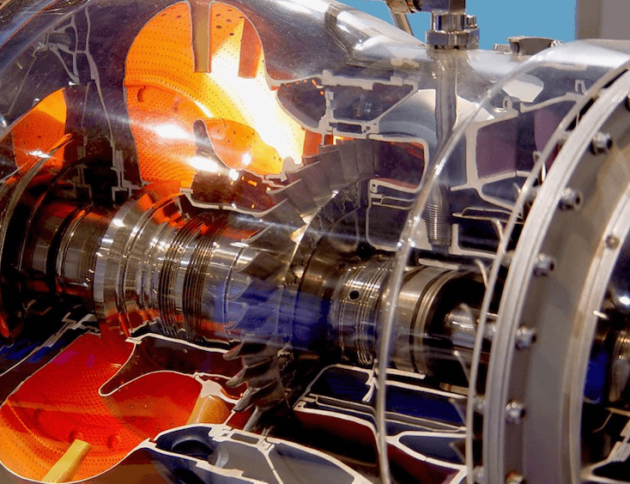

Industry of Aerospace

Aerospace vehicles, ranging from transport planes to space shuttles, require extremely accurate contraptions because a single inaccuracy might cause serious harm to the various aeronautical vehicles. Many components in this business are made using the CNC precise machining method, such as landing gear ports, bushings, manifolds, airfoils, and so on.

The Benefits of High-Precision Machining

For cost-effective and high-quality machining, precision and repeatability are critical prerequisites. CNC precision machining shines in a variety of ways to help meet performance and quality requirements. Among the benefits of this procedure are:?

Increased reliability and performance

While some applications may accept typical machining results, others have tight tolerances. These specifications require high-precision machining.

Most companies frequently demand many similar parts. This is only achievable with precise CNC machining and repeatability. Quality controls are constantly in place, with CNC machines making comparable cuts and ensuring equal quality in all pieces.

Advanced Machining Technology

Precision CNC machining equipment is an innovative technology that adheres to industry 4.0 requirements. It removes the need for extra labor and runs on the big gear.?

Computer programs now allow the automation of most tasks, regardless of the CNC machine tool used. They are “l(fā)ive operators” who use cutting instruments to mold various raw materials into desired end products.

Consistent part quality

The precise machining quality of CNC machines is unparalleled. Because of the use of computer numerical control, any variance associated with traditional machining is eliminated.

The procedure can last many hours and requires just minor maintenance and specialized software to match design requirements. As a result, even the most complicated components may be manufactured using modern procedures that assure the highest quality and surpass client expectations.

Wide range of applications

Precision machining procedures work with a variety of materials, including high-grade metals and polymers. This adaptability enables firms of all sizes to compete and provide unique designs and parts.

Achieving strict engineering tolerances regularly can help build consumer trust. Precision CNC machining may assist a variety of sectors, including automotive, metallurgy, aerospace, marine, agricultural, consumer products, and so on.

Lower labor costs and shorter cycle times

CNC precision machining can handle larger production needs due to improved machining automation and programming capabilities that do not require machine downtime. High-precision machines are built to be extremely exact and to provide reproducible results.

Traditional machining requires manual monitoring and modifications to the tools and operating rates. A CNC machine may run programs that were developed offline. A single-machine operator may switch between machining centers and handle many productions. The operator is to maintain load components and tools, as well as perform offline deburring and quality monitoring.

As a result, the structure requires extremely few operators for the monitoring process, lowering labor expenses. It also ensures faster component production, regardless of quantity.

Final Words

Precision machining is an art form, not just a procedure. Only highly skilled and motivated artisans and technicians can make the items you want.?

?

Lascia un commento

Il tuo indirizzo email non sarà pubblicato.