Thin wall sleeve is a difficult part to be machined in machining. Generally, turning and grinding methods are used, but none of them meet the requirements of design drawings. In order to solve the technical problems, through the innovative method of filling sawdust in the inner hole of the thin-wall sleeve and water injection expansion, the technological rigidity and machining accuracy of the thin-wall sleeve are improved, which can meet the technical requirements of the drawing.

Structure characteristics and accuracy requirements of thin wall part

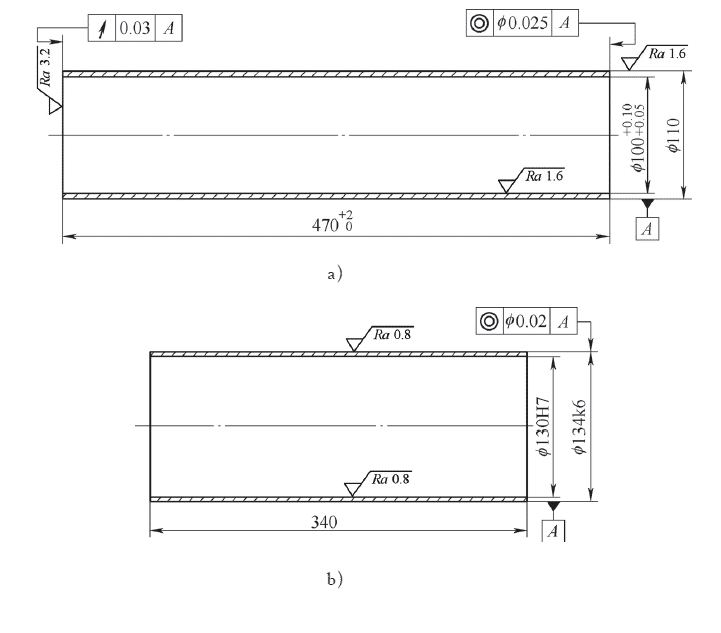

Process the thin-walled sleeve parts of two sizes as shown in Figure 1, and the material is 27SiMn Steel.

Thin wall sleeve processing technics

The processing route of workpiece I is: blanking → rough turning → semi finishing turning → centerless grinding → finishing turning → final inspection. The processing route of workpiece 2 is: blanking → tempering rough turning → semi finishing turning → final inspection. The machining features of the workpiece are as follows:

the machining of the workpiece surface is divided into rough, semi-fine and finish machining. During the machining, the trial cutting method is used to take the inner hole and outer circle as the benchmark for each other, and the machining is repeated. Finally, the inner hole is used as the reference to process the outer circle, meeting the technical requirements of the drawing.

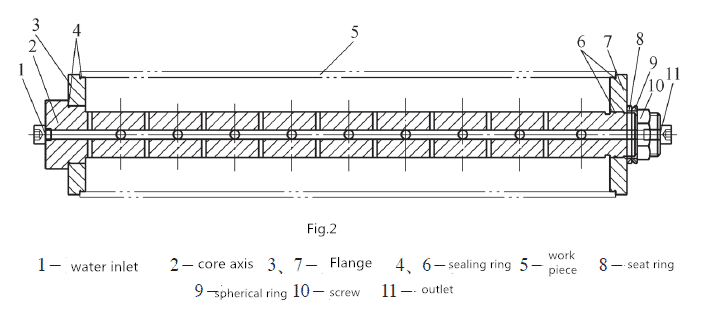

The processing outer circle adopts the process mandrel, and the structure is shown in Fig. 2.

Concrete Operation method

The specific processing methods are as follows.

a. Adjust the accuracy of the machine tool to meet the process requirements.

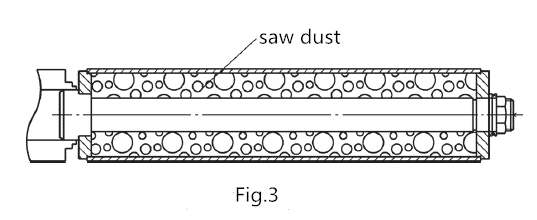

b. Processing process of workpiece I: first, process the inner hole of the workpiece to the size requirements, and rserve the outer circle appropriately according to the wall thickness; then, thread the mandrel into the hole, fill the sawdust and compact, align and inject water, wait for the sawdust to expand, and finish turning the outer circle to the size requirements of the drawing, as shown in Figure 3.

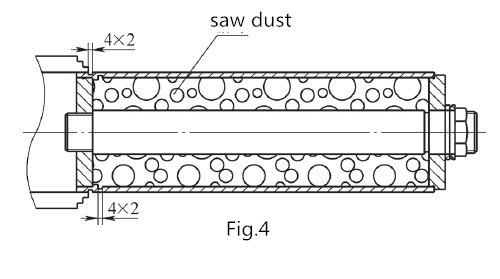

c. Machining process of workpiece 2: turn one end of the workpiece into a stop, and the fit clearance between the stop and the flange plate is 0.008-0.012mm. Cut 4mm × 2mm unloading grooves at the inner hole and the outer circle of the workpiece chuck, remove the workpiece, install flange plate 7, and make the workpiece chuck part become a solid state. The workpiece clamping is shown in Figure 4. Turn the inner hole to the size requirement. The outer circle should be reserved appropriately according to the wall thickness. Install the spindle rod into the hole and tighten it. Fill the sawdust and compact and inject water. After the sawdust expands, turn the outer circle to the size requirement.

Test results

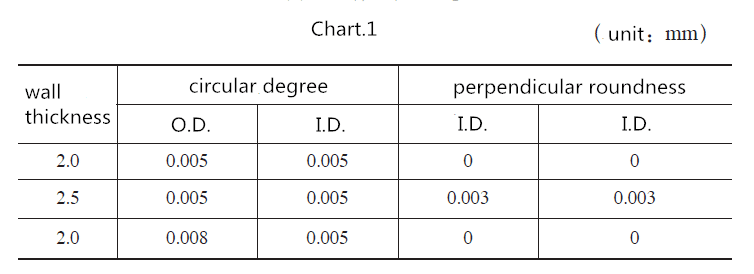

See Table 1 for product test results.

Qualitative analysis of water injection expansion method with sawdust

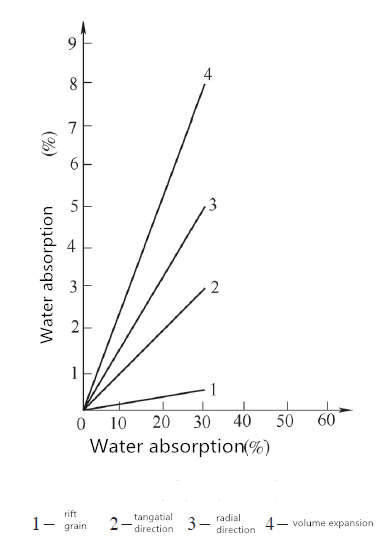

The test results of process test show that the thin-walled parts processed by filling sawdust with water injection expansion method can fully meet the technical requirements of the design drawings, which proves that this method is feasible. The method of adding sawdust is based on the principle of expansion of sawdust after absorbing water, which makes the inner hole and outer circle of the part become a whole, so as to reduce the deformation of the part in the process of processing. The expansion rate of sawdust after washing is analogized with that of wood, and the expansion rate is the largest when the fiber reaches the saturation point, as shown in Figure 5.

It can be seen from Figure 5 that the volume expansion rate of wood is the largest, and the expansion rate of sawdust is similar to the volume expansion rate of wood. Based on the principle of moisture absorption and expansion of sawdust, it has been applied to parts processing with good effect. After the sawdust is filled into the hole of the part and compacted for water injection, the expansion of the sawdust is constrained by the part and the mandrel. Because the expansion force acts on the inner wall of the part, two component forces, namely axial force and radial force, are formed. Under the action of these two forces, the part is basically in a solid state. Radial force can reduce the effect of Py force in turning process, and axial force can reduce the effect of PX force in turning process. On the other hand, the effect of cutting heat on the deformation of workpiece is obviously reduced by water injection. After the outer circle of the thin-walled sleeve is processed, the water injection port shall be opened, the inner hole pressure shall be unloaded, then the workpiece shall be disassembled, the inner hole of the thin-walled sleeve shall be cleaned, and the sawdust can be reused after drying.

conclusione

Through the process test of loading sawdust into the hole of the thin-wall sleeve for compaction and water injection, a feasible processing method is explored for the processing of the thin-wall sleeve. The method of filling sawdust with water injection expansion is especially economical and practical for single piece and small batch production.e