Experimental Methods

Raw Materials

The experiment uses coarse and extra-coarse WC powders from well-known suppliers, with their main characteristics shown in Table 1. Additionally, 2.0 μm cobalt powder from the same supplier was also used.

Experimental Methods

For the preparation of WC-10%Co (where all content is given in weight percentage), weigh 900 g of WC, 100 g of Co, and 20 g of PEG. Measure 235 mL of alcohol and 2000 g of grinding balls. Add these into a 2.4 L ball mill. The mill is operated at a speed of 63 r/min for 14.5 hours. After milling, the mixture is dried, sieved, and then pressed into samples weighing 10 g each. The samples are sintered in a continuous vacuum sintering furnace at 1450°C.

Particle Size Measurement

For coarse tungsten carbide, measure the Fischer particle size in both the as-supplied and milled states. The samples are resin-mounted and analyzed using a metallurgical microscope to determine the grain size and particle size distribution of the powder. The alloy grain size and particle size distribution are measured using classic metallographic methods, and the coercive force of the samples is also assessed.

Results and Analysis

Fischer Particle Size (Fsss) and Alloy Grain Size

As-Supplied Particle Size and Alloy Grain Size

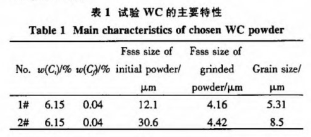

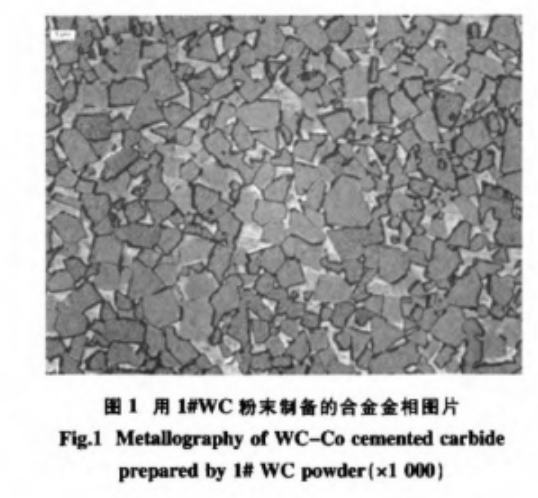

The metallographic images of alloys made from WC powders #1 and #2 are shown in Figures 1 and 2, respectively. Comparing Figures 1 and 2, it can be observed that the WC grain size in Figure 2 appears to be slightly coarser than in Figure 1. This indicates that coarser as-supplied Fsss particle sizes of WC lead to coarser grain sizes in the WC-Co alloys. Metallographic analysis shows that the average WC grain sizes for alloys made from powders #1 and #2 are 4.8 μm and 5.8 μm, respectively. Thus, the average grain size of WC in sample #2 is 1.2 times that in sample #1. The as-supplied Fsss particle size of #2 WC powder is 2.5 times that of #1 WC powder. Clearly, there is no direct proportional relationship between the as-supplied Fsss particle size of WC powder and the alloy grain size. Additionally, the Fsss particle size values for #1 WC powder are 2.5 times the alloy grain size, and for #2 WC powder, it is 5.3 times the alloy grain size. This indicates that the as-supplied WC powders for both samples are primarily aggregated polycrystalline WC particles, with more severe agglomeration for coarser WC powders.

Milled Dimensione delle particelle and Alloy Grain Size

Comparing Table 1 with the metallographic grain sizes in Figures 1 and 2, it can be seen that the Fsss particle sizes of milled WC powders #1 and #2 are relatively close to the alloy grain sizes. Moreover, the measured alloy grain sizes are higher than the milled Fsss particle size values. This discrepancy is due to differences in measurement principles as well as grain growth during the sintering process. However, it clearly indicates that the Fsss particle sizes of coarse WC powders in the milled state are very close to the alloy grain sizes. The ratios of average grain sizes to milled particle sizes for alloys #1 and #2 are 1.15 and 1.31, respectively.

Raw Material WC Grain Size and Alloy Grain Size

Results from Direct Metallographic Measurement

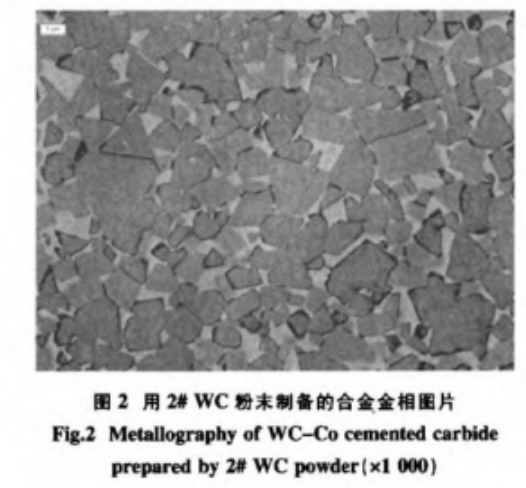

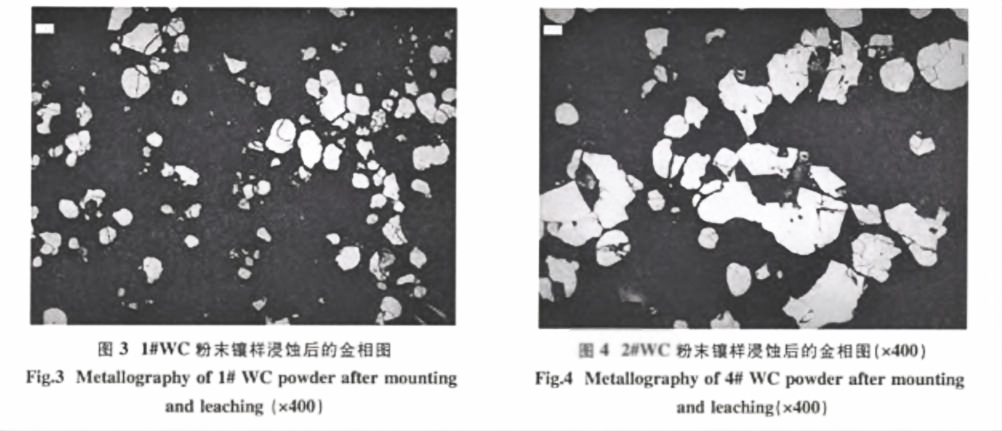

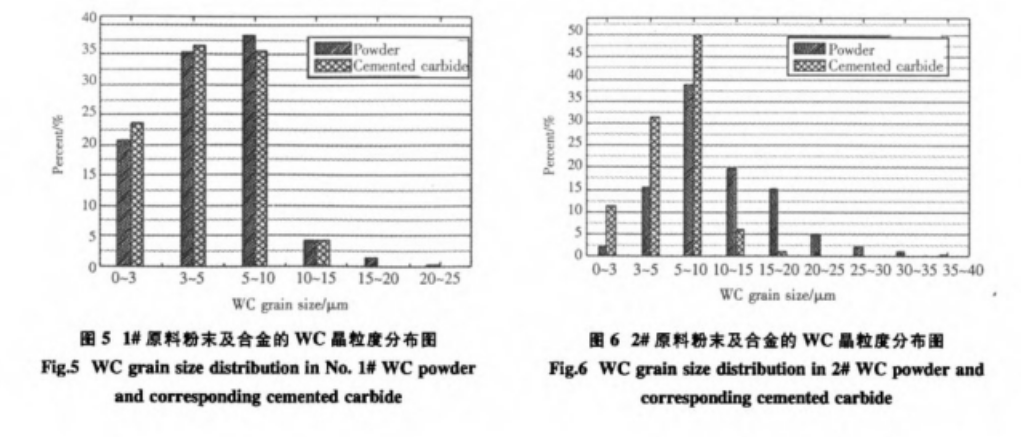

Metallographic images of #1 and #2 WC powders after mounting and etching are shown in Figures 3 and 4. The grain sizes measured using metallographic methods are 5.31 μm and 8.5 μm, respectively. The grain size distributions of the powders and alloys are shown in Figures 5 and 6.

Figures 3 and 4 clearly indicate that the grain size of #2 WC is significantly larger than that of #1 WC. This suggests that WC with a coarser as-supplied Fischer particle size also has coarser grains. Additionally, it is evident that #1 WC exhibits better dispersion, with less pronounced sintering between particles compared to #2 WC. The severe sintering in #2 WC particles is a major reason why the metallographic grain size is much larger than the alloy grain size, and also explains why the grains in #2 WC are much larger than those in #1 WC.

From the grain size distribution of the raw powders and alloys in Figures 5 and 6, it can be seen that sample #1 contains coarse WC grains of 15–20 μm in the raw material, which are not present in the alloy. In contrast, sample #2 has a substantial amount of WC grains in the 15–35 μm range, though only a small amount of 15–20 μm grains are found in the alloy. This suggests that the severe sintering of the mounted WC, although difficult to distinguish by metallographic methods after etching, was fragmented during the intense grinding process.

Moreover, comparing the WC and alloy grain size distributions in Figures 5 and 6 shows that the grain size distribution of WC in sample #1 is more consistent with the alloy grain distribution than in sample #2. This consistency is a significant reason why many researchers believe that WC similar to sample #1 is more conducive to producing coarse alloys with a more uniform grain size.

WC Particle Size and Alloy Coercive Force

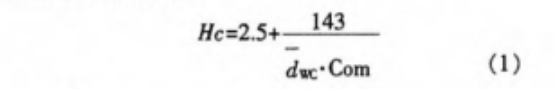

The coercive forces of the alloys made from #1 and #2 powders are 4.6 kA/m and 4.3 kA/m, respectively. The relationship between the WC-Co alloy grain size and the alloy’s coercive force can be expressed using the empirical formula (1).

In the formula:

- Hc= coercive force of the alloy (kA/m)

- Com= cobalt content in the alloy (%)

- Dwc= average WC grain size in the alloy (μm)

According to the calculations, the average grain sizes of alloys #1 and #2 are 7.4 μm and 8.8 μm, respectively. Clearly, the calculated grain sizes are significantly larger than the measured grain sizes, but the difference between the average grain sizes of alloys #2 and #1 is close to the difference observed using metallographic methods. The results obtained from formula (1) do not show a clear quantitative relationship with the Fsss particle sizes of the raw WC in both states, but the size of the raw material particles can still be used to predict the alloy grain size and coercive force.

Conclusions

Based on the above, the following conclusions can be drawn:

1.Coarse WC powders with larger as-supplied Fsss particle sizes tend to have higher milled Fsss particle sizes and larger grain sizes, leading to alloys with larger grain sizes.

2.The Fsss particle size in the milled state of coarse WC can be used to evaluate the grain size of coarse WC and predict the grain size of WC-Co alloys. Under the test conditions, the alloy grain size is 1.1 to 1.3 times the Fsss particle size of the milled WC.

3.Coarse WC powders with as-supplied Fsss particle sizes around 10 μm have a better consistency in grain size distribution with the alloy WC grain size distribution compared to extremely coarse WC powders with Fsss particle sizes above 25 μm.