Factors affecting cutting parameters

Cutting productivity

During the cutting process, the metal removal rate is linearly related to the three elements of cutting parameters ap, f, and v, which means that increasing any one of these parameters can increase productivity.However, considering the impact of tool life, when one of the parameters increases, the other two parameters must be reduced accordingly.Therefore, when we develop cutting parameters, the optimal combination of the three elements to achieve high productivity is the reasonable cutting parameter.Generally, in roughing situations, it is preferred to increase the cutting depth as much as possible to achieve a complete removal of the machining allowance in one pass.

Machine tool power

When the cutting depth and cutting speed increase, the cutting power increases.However, the feed rate has a relatively small impact on the cutting power.Therefore, when roughing, the feed rate should be increased as much as possible.

Durability of the tool

The rationality of cutting parameters directly affects the durability of the tool, which is what we call tool life. In order, they are cutting speed, feed rate, and depth of cut.Based on this order, we can conclude that in order to ensure the life of the tool, we should maximize the depth of cut;then choose a large feed rate;and finally calculate the cutting speed.

Surface roughness of processed surface

When performing finishing, increasing our feed rate will also increase the roughness value of the machined surface.This is the main factor affecting finishing.Under ideal conditions, increasing the cutting speed can reduce surface roughness;while the depth of cut has a relatively small impact on surface roughness.

Meetyou?Cemented Carbide Co., Ltd. believes that to choose reasonable cutting parameters, we should first choose a large cutting depth, then a large feed rate, and finally a reasonable cutting speed under the conditions of tool durability and machine power.

Approaches to selecting cutting parameters

There are many factors that can affect cutting parameters, such as tool material, tool geometric parameters, workpiece material, process category, processing steps, and specific usage conditions, such as cutting fluid, machine tool, fixture, and other factors. Therefore, when many fans ask about cutting parameters, there is actually no accurate answer. Most of them rely on experience.The uncertainty of various factors is difficult to quantify.At present, there is no method to accurately calculate cutting parameters. Therefore, there are generally three ways to develop cutting parameters:

Check the processing manual

Generally, the feed rate, cutting speed, and tool life can be found.The data in the manual can only be used as a reference, because the data in the manual is based on mathematical models established through cutting tests under specific conditions. The specific use conditions and test conditions are not the same as our actual use. We must make certain corrections based on the actual processing conditions.In the meantime, during the use process, we should make appropriate adjustments based on the processing conditions and processing effects to obtain the optimal cutting parameters.

Check the product catalogue of the tool manufacturer

Product brochures usually recommend corresponding cutting speeds and feed rates while introducing the products, although adjustments should be made based on actual conditions during use.

By cutting test

This method can obtain the most reasonable cutting parameters, but it is also the most expensive method. If the amount of processing is not large, it is not recommended to try it. We can try to keep the experimental conditions as close as possible to the actual working conditions to obtain the most accurate cutting parameters.

Method for selecting reasonable cutting parameters

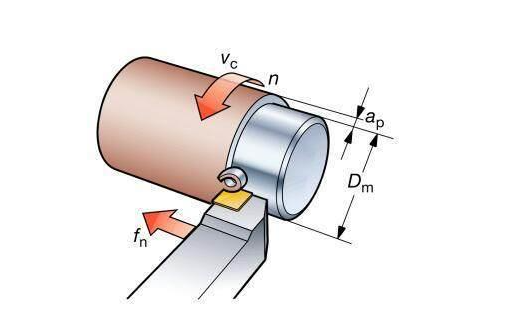

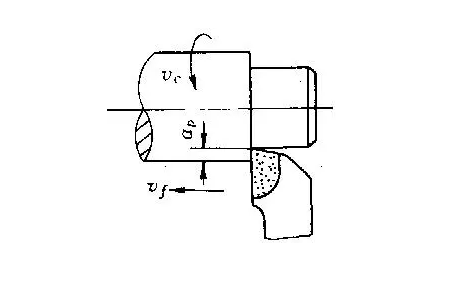

Selection method of back cutting depth: ap

We usually first select the back cutting depth, which is usually determined based on the nature of the process and the machining allowance.Then we also need to consider factors such as tool material, workpiece material, machine tool, and processing steps to make the most reasonable allocation of machining allowance.According to the productivity calculation formula for turning, P=A0vcfap (where A0 is a constant), increasing the back cutting depth will increase productivity in direct proportion. Furthermore, the back cutting depth has the least impact on tool life, and when the tool life is constant, increasing the back cutting depth is more beneficial than increasing the feed rate for improving productivity.Therefore, in rough machining, we try to take a large back cutting depth to reduce the number of feed passes and improve production efficiency.However, increasing the back cutting depth will increase the cutting force, especially when the cutting allowance is large, and the increase in back cutting depth should be allowed by the machine tool power and system rigidity conditions.When doing finishing or semi-finishing, the machining allowance should be taken to a smaller value to reduce the cutting force and deformation, so as to ensure the tool life and processing quality. However, for materials with severe work hardening, the minimum back cutting depth should exceed the depth of the hardened layer produced in the previous process.

The amount of back cutting is generally determined based on the nature of the process and the machining allowance.Cutting processes are generally divided into roughing (surface roughness value Ra=50-12.5μm), semi-finishing (Ra=6.3-3.2μm), and finishing (Ra=1.6-0.8μm).

In the following cases, multiple feeds should be used during rough machining:

1) When the machining allowance is too large, it can lead to excessive cutting force during one-time feed, which may result in insufficient machine power or insufficient tool strength, easily causing tool damage or even breakage.

2)When the process stiffness is relatively low or the machining allowance is extremely uneven, it can cause large vibrations.

3)In the case of intermittent cutting, the tool will be subjected to a significant impact causing a tool break.

Even in the above-mentioned circumstances, the back cutting amount for the first or previous feed should be as large as possible. If there are two feeds, the first feed should generally take 2/3 to 3/4 of the machining allowance.Try to make the back cutting amount exceed the thickness of the hardened or chilled layer to prevent premature tool wear.

Selection of feed rate: f

The effect of feed rate on tool life is much greater than that of cutting depth, but less than that of cutting speed.The feed rate can be selected based on the actual conditions such as the hardness and strength of the workpiece material, the material type of the tool, and the processing procedure, as well as based on experience or by consulting manuals, product brochures, and other materials.

When doing rough machining, if the quality requirements for the machined surface are not high, the cutting force is relatively large, and the choice of feed rate is mainly limited by the cutting force.We can choose a larger feed rate if the rigidity of the tool holder, insert, workpiece, and the strength of the machine feed structure allow it.

2) During finishing and semi-finishing, the cutting force generated is not large due to the small cutting depth. The selection of feed rate is mainly limited by the quality of the processed surface.When the tool has a reasonable transition edge and grinding edge, and a high cutting speed is used, the feed rate f can be appropriately selected to be larger in order to improve production efficiency.

Selection of cutting speed: v

The general principle for selecting the cutting speed during processing is:

1)During semi-finishing milling, the feed rate and back cutting depth are relatively large, so a lower cutting speed is selected;conversely, a higher cutting speed is selected for finishing milling.

When the hardness and strength of the workpiece material are high, a lower cutting speed should be selected.

2)Cutting steel in the quenched and tempered state requires a 20% to 30% reduction in cutting speed compared to cutting steel in the normalized and annealed state;cutting alloy steel requires a 20% to 30% reduction in cutting speed compared to cutting medium carbon steel;cutting non-ferrous metals requires a 100% to 300% increase in cutting speed compared to cutting medium carbon steel.

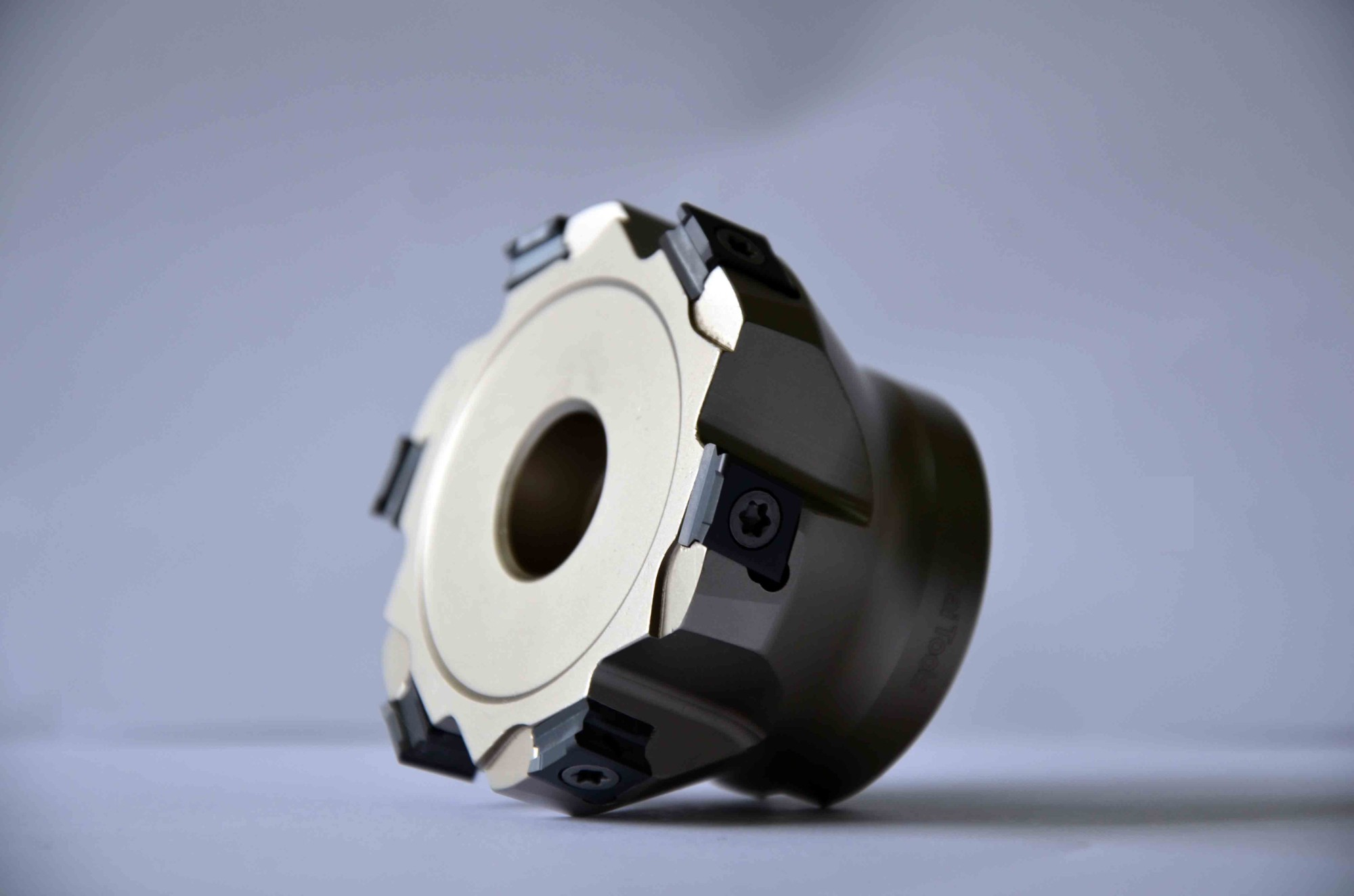

The better the cutting performance of the tool material, the higher the cutting speed. For example, the cutting speed of our carbide tool is several times higher than that of high-speed steel tool. The cutting speed of the tool with the center coating of the Pilates coating of Meituyou is higher than that of the uncoated tool.

When determining the cutting speed, the following aspects should also be considered:

1) During finishing, it is necessary to avoid the areas where scale spines and build-ups occur as much as possible.

2) When cutting intermittently, to reduce shock and thermal stress, the cutting speed should be appropriately reduced.

3) In the case of vibration, the cutting speed should avoid the critical speed of self-excited vibration.

4) When machining large workpieces, thin-walled workpieces, slender workpieces, or workpieces with outer skins, the cutting speed should be reduced.