Contenu

cacher

1. The contradictory characteristics of traditional uniform carbide

Cemented carbide is a typical brittle material. The traditional uniform carbide one, the material of the various parts of the uniform composition and organization, the alloy is homogeneous throughout, its performance is consistent. The main components of cemented carbide include various hard phases and binding phases. Hard phases such as phases and solid solutions play an important role in the hardness and wear resistance of alloys. Bonding has an important influence on the strength and toughness of alloys.

In general, increasing the WC grain size or increasing the Co content will increase the bond phase thickness of the alloy and improve the alloy plasticity. In alloys with good ductility, local concentrated stresses can relax the alloys with poor plasticity due to deformation. Crack initiation and propagation are induced by stress relaxation, resulting in cracking of the alloy.

Therefore, the traditional method is to increase the alloy. The content and increasing the grain size serve as a direction to increase the toughness of the hard alloy. However, at the same time, the hardness and wear resistance are reduced. Conversely, hardness and wear resistance can be increased without sacrificing flexural strength and impact toughness. Therefore, there is a sharp contradiction between the hardness and toughness of cemented carbide materials, and it is not easy to obtain a conventional uniform cemented carbide with high hardness and toughness at the same time. In many service conditions, the application of traditional uniform hard alloys will have certain limitations. For example, when the rock drill ball and the cobalt head are working, they are not only subjected to impact load and torsional load, but also have to be seriously worn by the rock.

This requires that the cobalt teeth not only have sufficient impact toughness but also have high The wear resistance can complete its work. When used in synthetic diamond synthesis, carbide top hammers are subjected to high temperature and high pressure, some parts are subjected to compressive stress, and some parts are subjected to tensile stress or shear stress. Different parts have requirements.

Different performance and features. In this way, the conflict between the hardness and toughness of the traditional uniform structure hard alloy restricts the further expansion of its application field, it is difficult to meet the “double high” high hardness and high toughness requirements for the development of modern society, so explore The new type of hard alloy material makes it particularly important that different parts of the tool have different functional requirements.

2. New advances in cemented carbide

The materials scientists of various countries in the world are trying to solve the above-mentioned contradictions in the traditional uniform hard alloy through various effective ways, reduce production and use costs, and improve their comprehensive performance. At present, there are mainly ultra-fine and nano-hard alloys (so-called ultra-fine cemented carbide is an alloy with a tungsten carbide grain size of 0.2-0.5 μm, and nano-hard alloy is an alloy with a tungsten carbide grain size of less than 0.2 μm. ), platelet toughened carbide, coated carbide and functional gradient carbide, and other directions can effectively solve this contradiction. For example, when the cobalt content of the nano-size hard alloy is high, not only has good fracture performance, but also has a high hardness, reaching the best combination of alloy toughness and hardness functional gradient carbide by making the binder phase or hard phase along One direction is increasing or decreasing to give the different parts of the alloy different properties, so that the combination of toughness and wear resistance can be fully achieved in the use of the carbide. The following is a brief introduction to the new progress of gradient cemented carbide.

Functionally Graded Cemented Carbide

3. Gradient carbide proposed

Abrupt changes in material composition and properties in the component often lead to significant local stress concentrations, whether the stress is internal or external. If the transition from one material to another is performed gradually, these stress concentrations will greatly increase. reduce.

These considerations form the basic logical element of most functionally graded materials. Japanese scientists first proposed functionally graded materials, which are characterized by the introduction of gradual changes in the microstructure and/or composition of a component, the gradual change of its microstructure and/or composition in space, and the physical, chemical and mechanical properties of the material.

The performance exhibits a corresponding gradient change in space, so that it meets different performance requirements at different locations in the component, thereby making the component as a whole achieve the best results.

This design idea was introduced in the field of cemented carbide in the mid-to-late 1980s, and a gradient cemented carbide was proposed, and rapid development was quickly achieved. In the actual use of cemented carbide, different working sites often have different performance requirements. For example, the cemented carbide cobalt head requires high surface wear resistance and overall impact resistance.

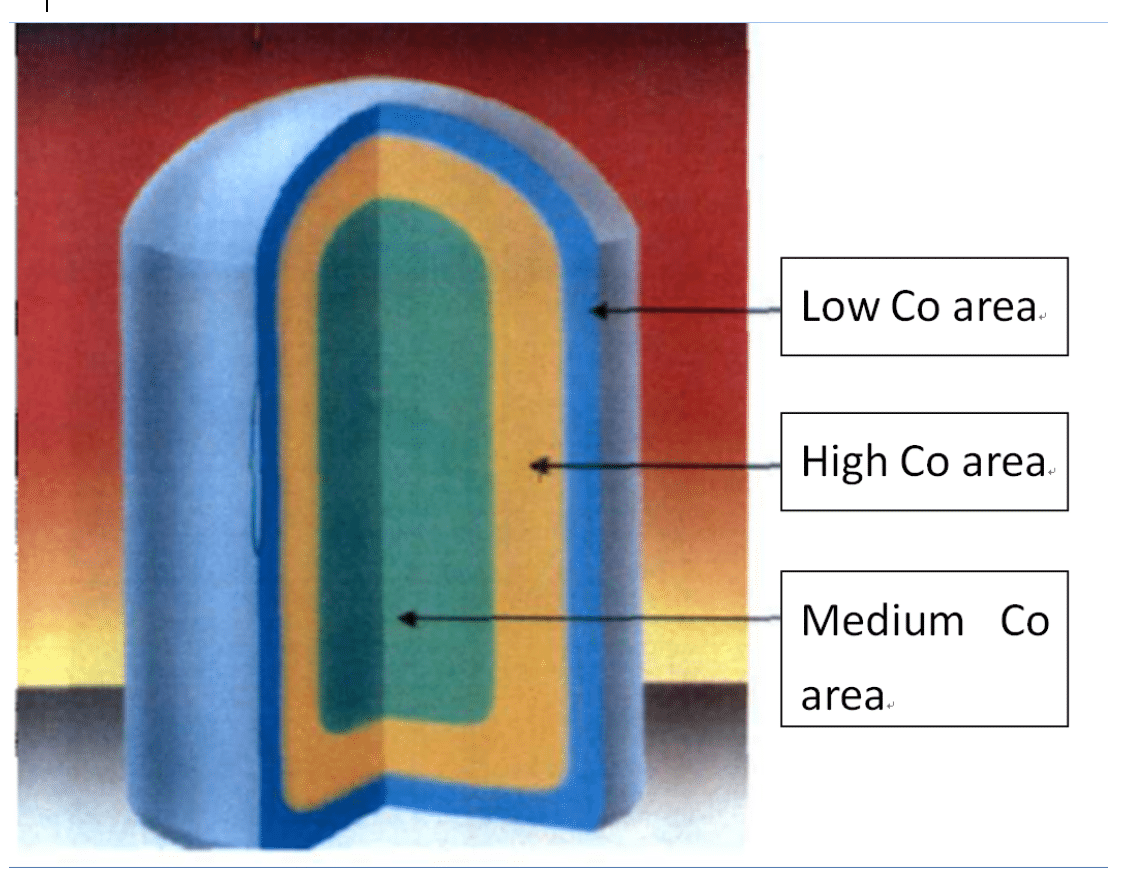

It is conceivable that if a new type of cemented carbide material can be developed, the structural feature of this material is that the surface layer is a structure with a low binder phase and the binder phase content of the core is an average value, between the surface layer and the core. It is a transition layer with a high binding content and a continuous distribution. In this kind of structure, due to the different distribution of bonding phase in each part, the content of the bonding layer in the alloy surface is lower than the average value in each part, with high hardness and good wear resistance, and the binding layer content in the transition layer. High, can meet good toughness and impact resistance.

4. Properties of gradient cemented carbide

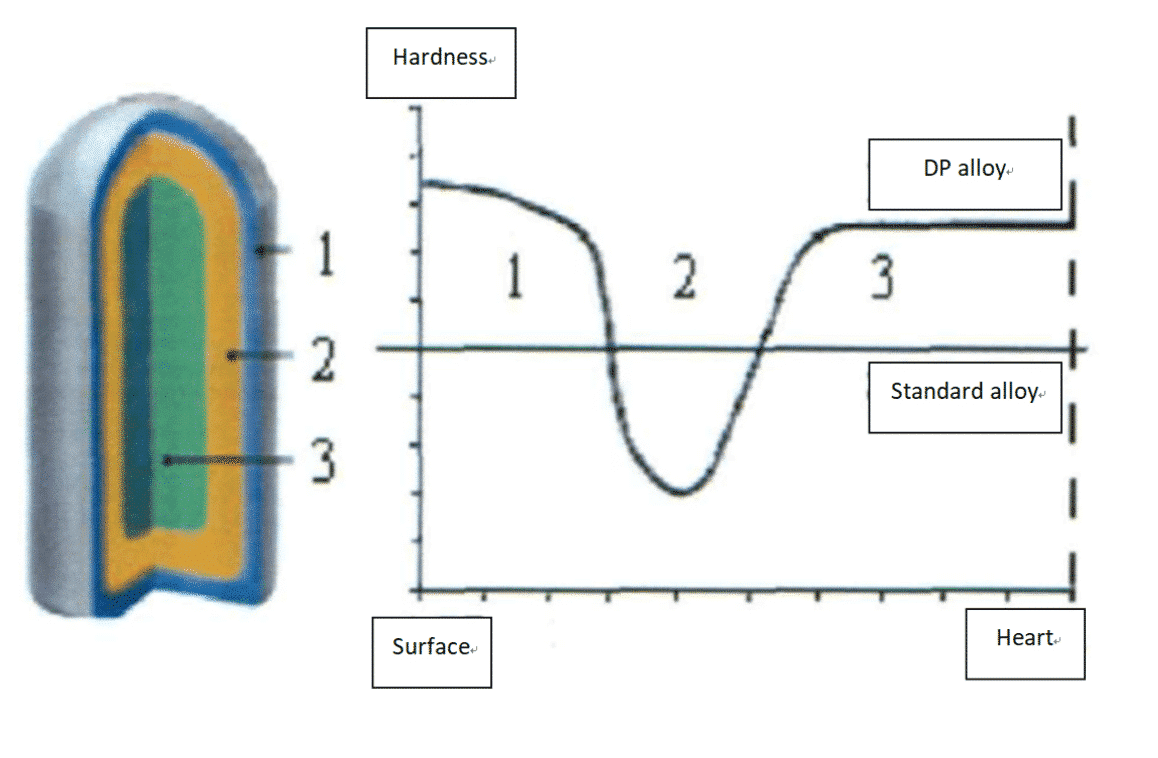

In the two-phase structure, the cobalt content of the surface layer is lower than the nominal cobalt content of the alloy, the cobalt content of the intermediate layer is higher than the nominal cobalt content of the alloy, and the cobalt content of the core containing the η phase is the nominal cobalt content of the alloy. As the cobalt content of the alloy shows a gradient change, the hardness of the different parts of the alloy also reflects the corresponding laws. Moreover, the gradient distribution of cobalt content makes the sintering shrinkage in different parts of the cross section non-uniform, resulting in residual stress in the alloy. Due to the low content of cobalt in the surface layer of the alloy and the high content of WC+Co+η, the surface of the alloy has very high hardness and very good wear resistance. In the middle layer of the alloy, the cobalt content is higher than the nominal content of the alloy, and thus The layer has good toughness and plasticity, so that the alloy can withstand higher loads. The η phase structure inside the alloy has good rigidity. The experimental results show that the wear resistance and toughness of DP alloy are obviously better than that of the traditional uniform hard alloy. The adoption of DP alloy can obviously improve the efficiency of rock drilling and reduce the mining cost.

According to the current research status of gradient materials in various countries, there are mainly three types of gradient cemented carbide bonded phase composition carbides such as alloys, hard phase composition gradient cemented carbide (such as the β-layer used as a coating matrix. Gradient cemented carbide) and hard phase grain size gradient cemented carbide (such as grain-gradient cemented carbide top hammer).

5. Gradient formation mechanism

The viewpoint of the formation mechanism of the gradient distribution of the cobalt phase caused by the directional migration of the liquid binder phase in the alloy after carburizing has not yet been unified. According to current research reports, the directional migration of liquid phase mainly includes mass migration caused by three different types of liquid phases, orientational migration of binder phase caused by different WC particle sizes, and liquid phase migration caused by different carbon content. For example, two YG alloys with the same WC carbon content, uniform particle size, and different binder cobalt content are overlapped and held at the liquid phase temperature for a certain period of time. As a result, the bound cobalt phase shifts from a high cobalt content to a low cobalt content. One side of the migration,.

For example, one of different particle sizes is fine particles, and the other is coarse particles added with the same cobalt to form two kinds of mixture, and pressed into a double-layer alloy for vacuum sintering. The liquid binding phase appears to be fine from one side to the other. The grain side migrates. While the high carbon cemented carbide is decarburized in the decarburizing atmosphere, the liquid binding phase will migrate from the inside to the surface of the sample, while the low carbon alloy will migrate to the center after the carburizing treatment liquid binding phase.

The phenomenon of migration caused by the difference in carbon content is caused by the difference in the amount of liquid phase in the different parts of the alloy. This type of decarburized or carburized alloy has an unequal internal carbon content, and the carbon content is relatively high in regions with high carbon content. In regions with lower carbon content, the liquid phase migrates from areas with high carbon content to areas with low carbon content. Taken together, the main mechanisms of liquid phase migration are:

The binder phase migrates from the coarse-grained carbide region to the fine-grained carbide region, and the driving force for the migration is the capillary pressure difference, that is, the action of the capillary force. The binding phase migrates from the high liquid phase region to the low liquid phase region and migrates. The driving force is the pressure difference in the liquid phase, that is, the role of volume expansion or contraction to generate pressure when the state of the substance in the liquid phase volume difference changes.

6. Application of Gradient Cemented Carbide

Gradient cemented carbide successfully solves the contradiction between hardness and toughness existing in conventional homogeneous cemented carbide. The development of this new material is considered to be the most important one in the history of cemented carbide since the 1950s. Innovation.” Due to the unique microstructure and properties of gradient cemented carbide, it has become an important research content in the field of gradient functional materials and hard alloys. Currently, it has been widely used in coating substrates, carbide cutting tools, mining and rock drilling tools, stretching dies and punching tools, and its application fields are constantly expanding.

(1) Used as a coating substrate

Due to the different thermal expansion coefficients of different materials, coating tool materials may crack due to thermal stress during cooling. Gradient structure cemented carbide is used as the matrix, that is, the gradient-sintered coating matrix forms a ductile region lacking cubic carbides and carbonitrides in the surface region, which can effectively prevent cracks formed in the coating from expanding into the interior of the alloy. , improve the interface bonding strength and reduce interface stress concentration, thereby improving the performance of carbide cutting tools.

(2) Used as a carbide tool

Change the traditional cemented carbide. The constant proportion model is used to make a graded structure hard alloy with low surface content and high core content, so that the surface layer has high hardness and good wear resistance, while the core has high strength and good impact toughness, which makes the strength and toughness of the alloy. It is well coordinated and can therefore be used to produce cutting tools with both wear resistance and toughness.

(3) Mining and rock drilling tools Mining and rock drilling tools

The use of ball teeth requires greater wear and impact during operation, which requires the alloy to have high surface wear resistance and high strength. Conventional uniform alloys are difficult to meet this requirement. Both wear resistance and toughness are significantly better than conventional uniform carbides.

(4) Used as a punching tool

Sheet metal is usually prepared by punching or punching. With this method, the material is broken between working edges that face each other. During punching, the punch moves through the die in a direction perpendicular to the metal plate and punches the metal plate. The failure mode of the punch is usually due to the wear of the working edge and eventually leads to the cutting edge of the punch becoming conical, thereby increasing the frictional force during punching and eventually leading to a decrease in punching quality. In order to increase the life of the gradient carbide cutting tool as much as possible, a graded cemented carbide with a central η-phase region should be used, surrounded by a nucleus-free surrounding region, and with an exposed working surface of the η-phase. Using cemented carbide as the punch, the grain size of WC is 2-3μm, the number of punching times for standard cemented carbide is only 15 times, and the number of punching and shearing of cemented carbide for gradient structure is up to 64,000 times, while that of steel die punching The number is about 7231 times. It can be seen that gradient cemented carbide as a punching tool can greatly improve the service life of the tool.

The study of gradient cemented carbide consists of three parts: material design, material preparation, and property evaluation. These three parts complement each other and are indispensable. Material preparation is the core of the gradient cemented carbide research. The material design provides the best composition and gradient distribution of the structure. To judge whether the designed and prepared material meets the predetermined function, performance evaluation must be performed.

7. Gradient Cemented Carbide Design

Gradient cemented carbide design, generally should go through the following several links First according to the structural shape of the components and the actual conditions of use, draw the thermodynamic boundary conditions from the existing material synthesis and performance database, select the possible synthesis of metal-ceramics Material combination system and preparation method Assume the combination ratio and distribution rule of the binder phase and the hard phase, and use the material microstructure mixing law to derive the equivalent physical parameters of the material structure using the thermoelastic theory and the calculation mathematics method. The distribution function of the gradient components of the material structure is simulated by temperature distribution and simulated by thermal stress, and the optimal composition distribution and material system are designed. The core work of gradient cemented carbide design consists of the following three parts:

(1) Establish an appropriate gradient component distribution model so that the gradient functional material designed meets the performance requirements

(2) Estimating physical properties of gradient materials

(3) Calculation of temperature field and thermal stress of functionally graded materials

See our tungsten carbide mining button bits ici