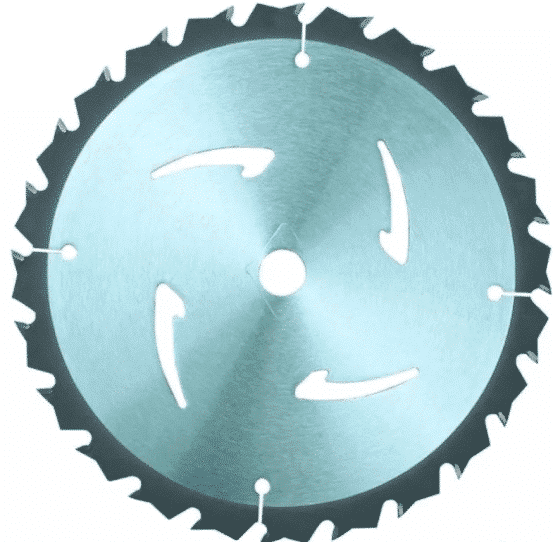

1: How to repair the saw blade?

The quality of the saw blade directly affects the service life of the saw blade. Good grinding should be carried out on fully automatic equipment. The grinding wheel should not be fed too fast, and the grinding time should be no less than 30 minutes.

2: When sawing the return, the saw blade is swept?

Cause: The motor shaft of the device has a large jump, or the saw blade has a large swing.

3: Why is there a glitch?

The saw blade alloy is not sharp, and burrs are generated when the cutting cannot be continued. The saw blade needs to be ground when the burr occurs.

4: What are the hazards of inferior saw blades?

The cutting time is short, the replacement is frequent, and time is wasted. Accuracy is not up to standard and waste material. Damage to the equipment spindle and motor, and shortened equipment life. Safe travel, easy to hurt people.

5: Why are there scratches on the cutting section?

There are many reasons for scratches: materials have impurities, saw blade defects, equipment motor and spindle deviation.

6: Why is there a tooth loss (alloy off)?

Alloy shedding is caused by inferior soldering or welding equipment. The high-quality soldering piece should be three layers of silver-copper-silver, and the inferior saw blade has only silver-copper two layers.

7: Why is there a saw blade sticking phenomenon?

Sticky teeth are usually not matched by the saw blade and equipment power and feed speed, and should be selected according to equipment power and cutting material.

8: Why does the broken tooth (alloy break) occur?

The broken teeth are usually too large due to the front angle of the saw blade. The excessive front angle will significantly improve the first service life, but the life after grinding is significantly reduced, and the safety risk of the user is increased. In addition, uneven material material may also cause broken teeth.

9: Is the life of the saw blade short?

The saw blade is made of inferior steel or alloy, the saw blade does not match the equipment or profile, and the saw blade design is reasonable.

10: How to choose the right saw blade?

The user should provide the equipment status and cutting material grade/cross-sectional shape. The high-quality saw blade has a good appearance: the tooth is welded evenly and the alloy is bright and sharp. Also mark the manufacturer information for after-sales service.

11: The door and window are cut to the upper corner?

The saw blade is in a beveled working condition (45 degrees or 22.2 degrees) and requires a high degree of the saw blade base (steel plate). Inferior steel plates do not work well in the chamfered state.

12: How is the life of the saw blade calculated?

Life = number of saws * cross-sectional area. Number of saws = number of new saws The number of cuts after grinding until scrapped. The number of cuttings of a high-quality saw blade is only 5-15% after each grinding. Inferior quality will have a decline of more than 50%.

Correct use of carbide saw blades:

1. The alloy cutter head of the carbide circular saw blade has a sharp and hard cutting edge, so the alloy knife must be carefully protected during the process of moving, installing or disassembling the saw blade.

The head is protected from damage.

2. Check the spindle of the woodworking machine for important parameters such as deformation, vibration, axial deflection, etc., to avoid unstable mechanical influence on cutting quality, and regularly check the radial runout (0.02mm) of the machine shaft and the deviation range (0.01mm)

3. The operator must wear protective glasses and install a protective cover on the woodworking machinery.

4. The sawdust, the spindle and the sawdust on the flange must be cleaned to avoid improper errors affecting the cutting quality.

5. the flange size is 1/3 of the diameter of the saw blade (multi-chip saw should use 1/2 flange) sawing effect is better (especially thin saw blade), so that the saw blade works better and smooth.

Note: In the following cases, it is necessary to repair in time.

(1) When the sawing surface no longer meets the requirements

(2) When the energy consumption of the machine tool is significantly increased or it is difficult to push the cutting

(3) When the edge of the cutting material is obviously cracked

(4) When the alloy edge wear reaches 0.2 mm.

Maintenance and maintenance of carbide circular saw blades

Timely grinding is very important, because the saw blade with passivated edge is easy to cause the saw blade to shake due to the increased resistance, and the motor load is increased, which will cause damage to the saw blade and the machine. Continue cutting when grinding should be done. For every 10% increase in cutting, it will bring about 50% more alloy damage and shorten the life of the saw blade. Resin, debris and other debris accumulated on the sides of the serration must be removed frequently, because the accumulation of the adhesive will increase the resistance, resulting in high energy consumption (in extreme cases, the motor of the machine will burn) and rough cutting quality. . If the cutting edge is blunt at the same time, it may cause damage to the sawtooth. When storing, they should be placed separately, not stacked and placed on metal objects, preferably in the original carton for movement and removal.

Carbide sawtooth grinding

The use of a precision, stable vibration-free sharpening machine, as well as a suitable diamond grinding wheel, to repair the alloy head according to the specified operating procedures will extend the life of the saw blade. Do not use hand-operated sharpening equipment. The resin, debris, etc. adhering to the saw blade must be cleaned with a cleaning agent before grinding.