The systematic mechanical related deviation of machine tool can be recorded by the system, but due to environmental factors such as temperature or mechanical load, the deviation may still appear or increase in the subsequent use process. In these cases, SINUMERIK can provide different compensation functions. The deviation is compensated by using the measured value obtained by the actual position encoder (such as grating) or additional sensor (such as laser interferometer, etc.), so as to obtain better machining effect.

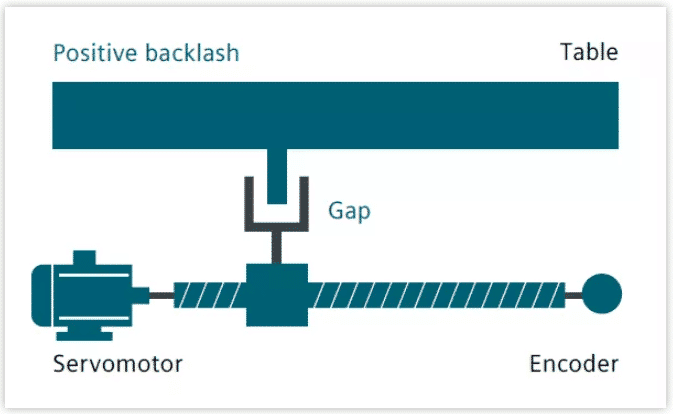

The transmission of force between the moving parts of the machine tool and its driving parts, such as the ball screw, will produce discontinuity or delay, because the mechanical structure without clearance will significantly increase the wear of the machine tool, and it is also difficult to realize in terms of technology. The mechanical clearance causes a deviation between the movement path of the shaft / spindle and the measured value of the indirect measurement system. This means that once the direction changes, the axis will move too far or too close, depending on the size of the gap. The worktable and its associated encoder will also be affected: if the encoder position is ahead of the worktable, it reaches the command position ahead of time, which means that the actual moving distance of the machine tool is shortened. In the operation of the machine tool, by using the reverse clearance compensation function on the corresponding axis, the previously recorded deviation will be automatically activated when reversing, and the previously recorded deviation will be superimposed on the actual position value.

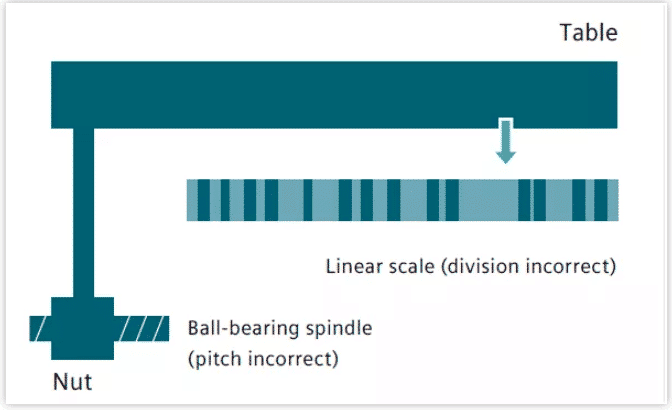

Screw pitch error compensation

The measurement principle of indirect measurement in CNC control system is based on the assumption that the pitch of ball screw remains unchanged in the effective stroke, so in theory, the actual position of the linear axis can be deduced according to the motion information position of the driving motor. However, the manufacturing error of the ball screw will lead to the deviation of the measurement system (also known as the screw pitch error). The measurement deviation (depending on the measurement system used) and the installation error of the measurement system on the machine tool (also known as the measurement system error) may further aggravate this problem. In order to compensate these two kinds of errors, a set of independent measurement system (laser measurement) can be used to measure the natural error curve of CNC machine tools, and then the required compensation values are saved in the CNC system for compensation.

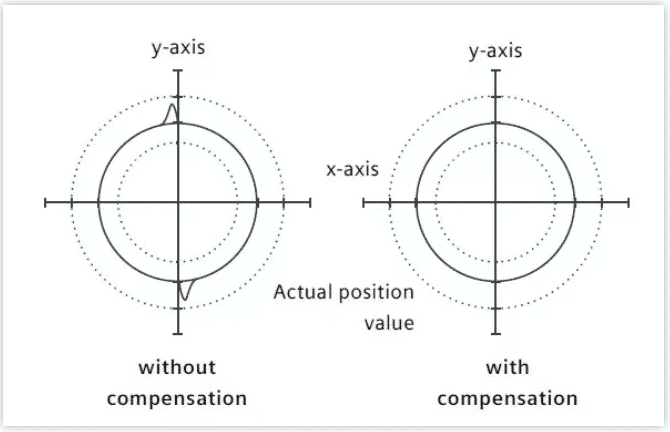

Friction compensation (quadrant error compensation) and dynamic friction compensation

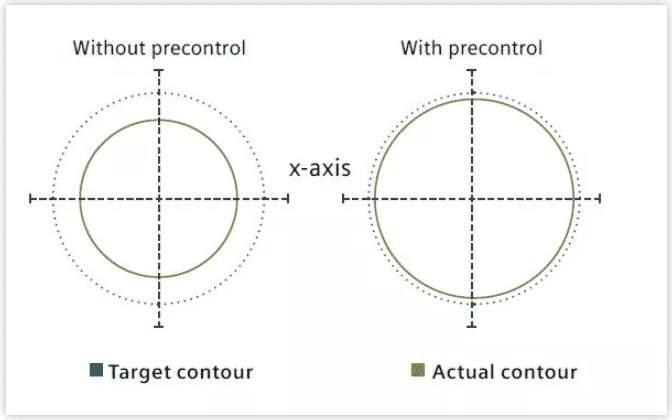

Quadrant error compensation (also known as friction compensation) is suitable for all the above situations, so as to greatly improve the contour accuracy when machining circular contour. The reason is as follows: in quadrant conversion, one axis moves at the highest feed speed, and the other axis is stationary. Therefore, the different friction behavior of two axes may lead to contour error. Quadrant error compensation can effectively reduce this error and ensure excellent machining effect. The density of compensation pulse can be set according to the characteristic curve related to acceleration, which can be determined and parameterized by roundness test. In the roundness test, the deviation between the actual position of the circular contour and the programmed radius (especially when reversing) is recorded quantitatively, and displayed on the human-machine interface through graphics.

In the new version of the system software, the integrated dynamic friction compensation function can dynamically compensate the friction behavior under different rotating speeds of the machine tool, reduce the actual machining profile error, and achieve higher control accuracy.

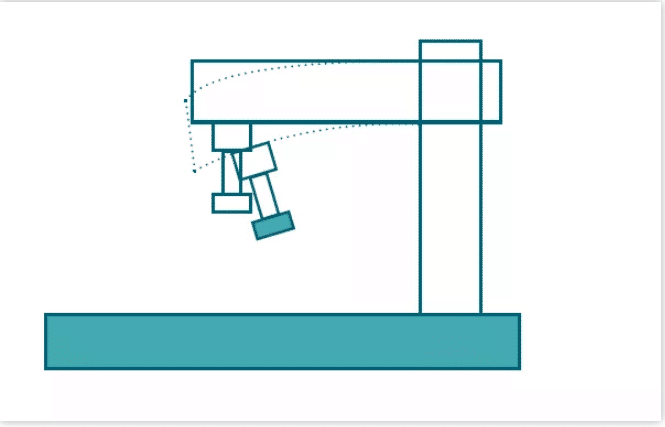

Sag and angle error compensation

If the weight of the individual parts of each machine tool will cause displacement and inclination of the moving parts, sag compensation is required because it will cause sagging of the relevant machine parts (including the guide system). Angle error compensation is used when the moving axes are not aligned with each other at the correct angle (for example, vertical). With the increase of the offset of the zero point position, the position error also increases. Both of these errors are caused by the weight of the machine tool, or by the weight of the tool and the workpiece. After the measured compensation value is quantified during debugging, it is stored in SINUMERIK according to the corresponding position in some form, such as compensation table. When the machine is running, the position of the relevant axis is interpolated according to the compensation value of the storage point. For each successive path movement, there are basic axis and compensation axis.

temperature compensation

Heat can cause expansion of various parts of the machine. The expansion range depends on the temperature and thermal conductivity of each machine part. Different temperature may cause the actual position of each axis to change, which will have a negative impact on the accuracy of the workpiece in processing. These changes in actual values can be offset by temperature compensation. The error curves of each axis at different temperatures can be defined. In order to compensate the thermal expansion correctly all the time, the temperature compensation value, reference position and linear gradient angle parameter must be transferred from PLC to CNC control system through function block. The change of unexpected parameters will be automatically eliminated by the control system, so as to avoid overloading the machine and activate the monitoring function.

Space error compensation system (VCS)

The position of the rotating shaft, their mutual compensation and the orientation error of the tool may lead to systematic geometric errors of the rotating head, the rotating head and other components. In addition, there will be small errors in the guide system of the feed shaft in each machine tool. For linear axis, these errors are linear position errors, horizontal and vertical straightness errors, and for rotation axis, pitch angle, yaw angle and roll angle errors will be generated. Other errors may occur when the machine components are aligned with each other. For example, vertical error. In a three-axis machine tool, this means that 21 geometric errors may occur on the tool tip: Six error types per linear axis multiplied by three axes, plus three angular errors. These deviations together form the total error, also known as the spatial error.

The space error describes the deviation between the tool midpoint (TCP) position of the actual machine tool and that of the ideal error free machine tool. SINUMERIK solution partners are able to determine spatial errors with the help of laser measurement equipment. It is not enough to measure only the error of a single position. It is necessary to measure all the machine errors in the whole machining space. Generally, it is necessary to record the measured values of all positions and draw a curve, because the size of each error depends on the position of the relevant feed axis and the measured position. For example, when the Y-axis and z-axis are in different positions, the deviation caused by the x-axis will be different – even in almost the same position of the x-axis. With the help of “cycle996 – motion measurement”, it takes only a few minutes to determine the axis of rotation error. This means that the accuracy of the machine tool can be constantly checked and, if necessary, corrected even in production.

Deviation compensation (dynamic feedforward control)

Deviation refers to the deviation between the position controller and the standard when the machine tool axis moves. The axis deviation is the difference between the target position of the machine axis and its actual position. The deviation leads to unnecessary contour errors related to velocity, especially when the curvature of contour changes, such as circle, square contour, etc. With the help of the NC high level language command ffwon in the part program, the speed related deviation can be reduced to zero when moving along the path. The feed-forward control is used to improve the path precision, so as to obtain better machining effect.

Electronic counterweight compensation

In extreme cases, the electronic counterweight function can be activated in order to prevent the shaft from sagging and causing damage to the machine, tool or workpiece. In a load shaft without a mechanical or hydraulic counterweight, the vertical shaft will sag unexpectedly once the brake is released. When the electronic counterweight is activated, it can compensate for unexpected shaft sagging. After the brake is released, the position of the droop shaft is maintained by a constant balance torque.