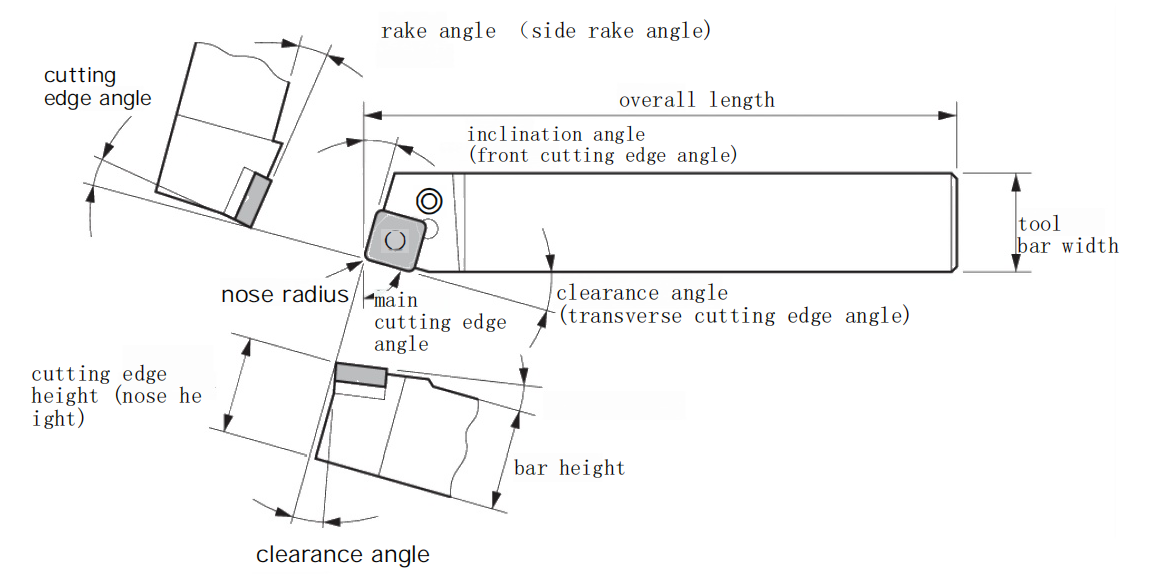

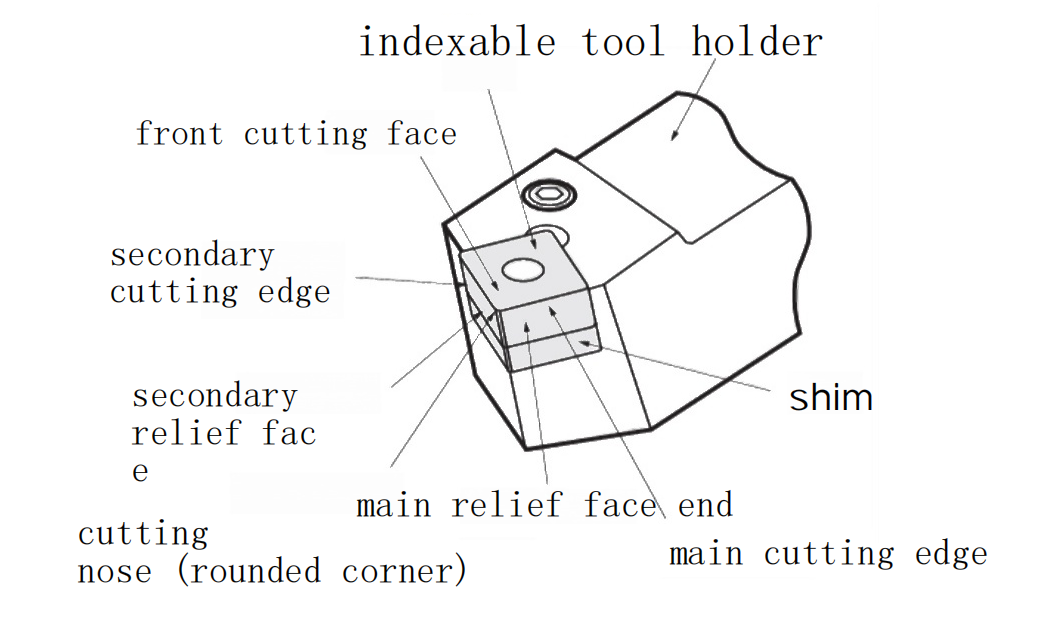

The Functions of the Different Parts of the Turning Tool

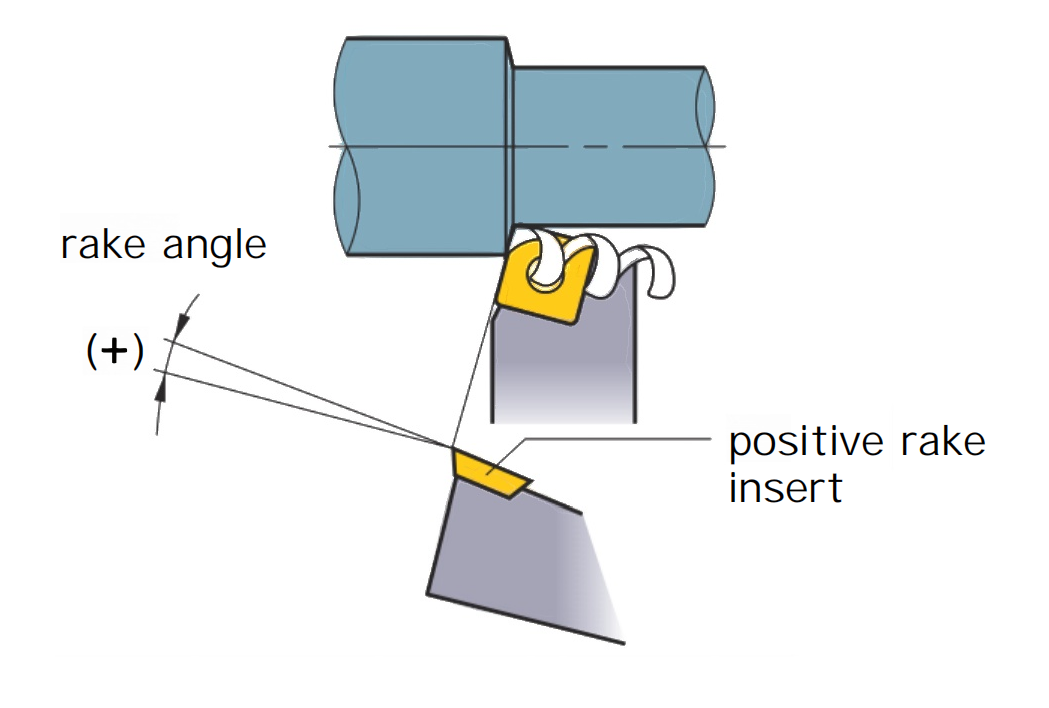

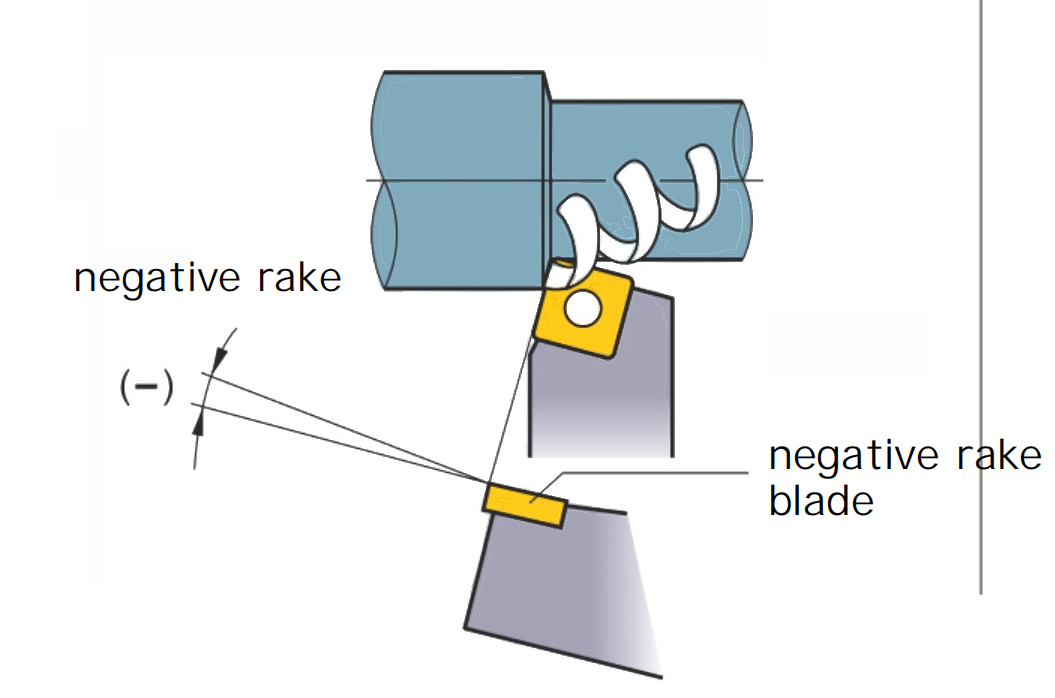

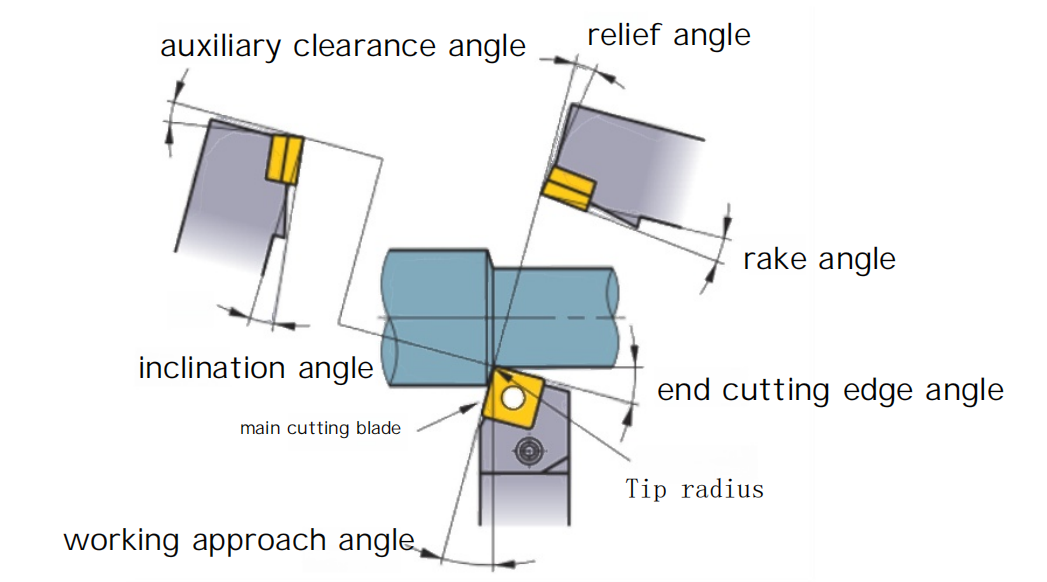

?Rake angle

The rake angle is the angle between the cutting face and the reference plane; it is an important indicator of how the cutting edge participates in the cutting process. The rake angle of the blade itself is usually a positive rake angle, and the shape of the cutting face can be a circular arc, chamfer, or flat surface. The size and sign (positive or negative) of the rake angle will affect the tool strength, cutting force, the tool’s finish machining capability, vibration tendencies, and chip formation. The rake angle has a significant impact on cutting force, chip evacuation, cutting heat, and tool life.

Impact of rake angle?size on cutting

1.A larger positive rake angleresults in a sharper cutting edge, but the strength of the cutting edge decreases.

2. A larger positive rake angle?reduces the cutting force; an excessively large negative rake angle?increases the cutting force.

?

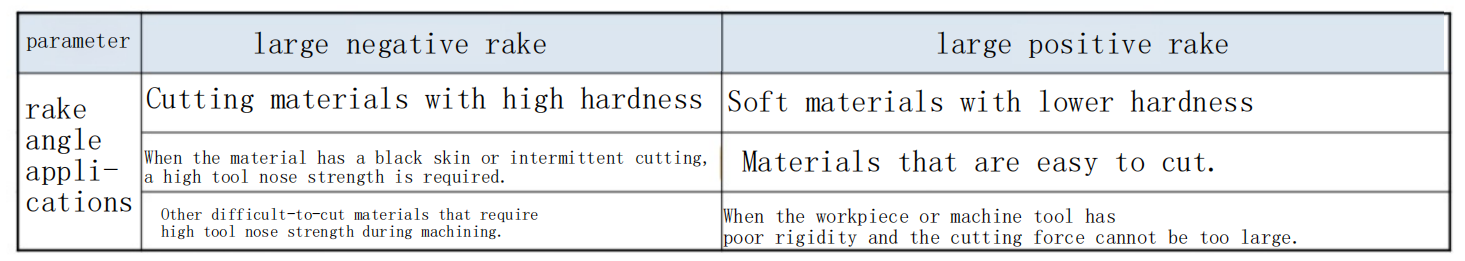

Applications of different rake?angle sizes

Relief angle

The relief angle has the function of avoiding the friction between the back tool face and the workpiece and making the tool tip cut into the workpiece freely.

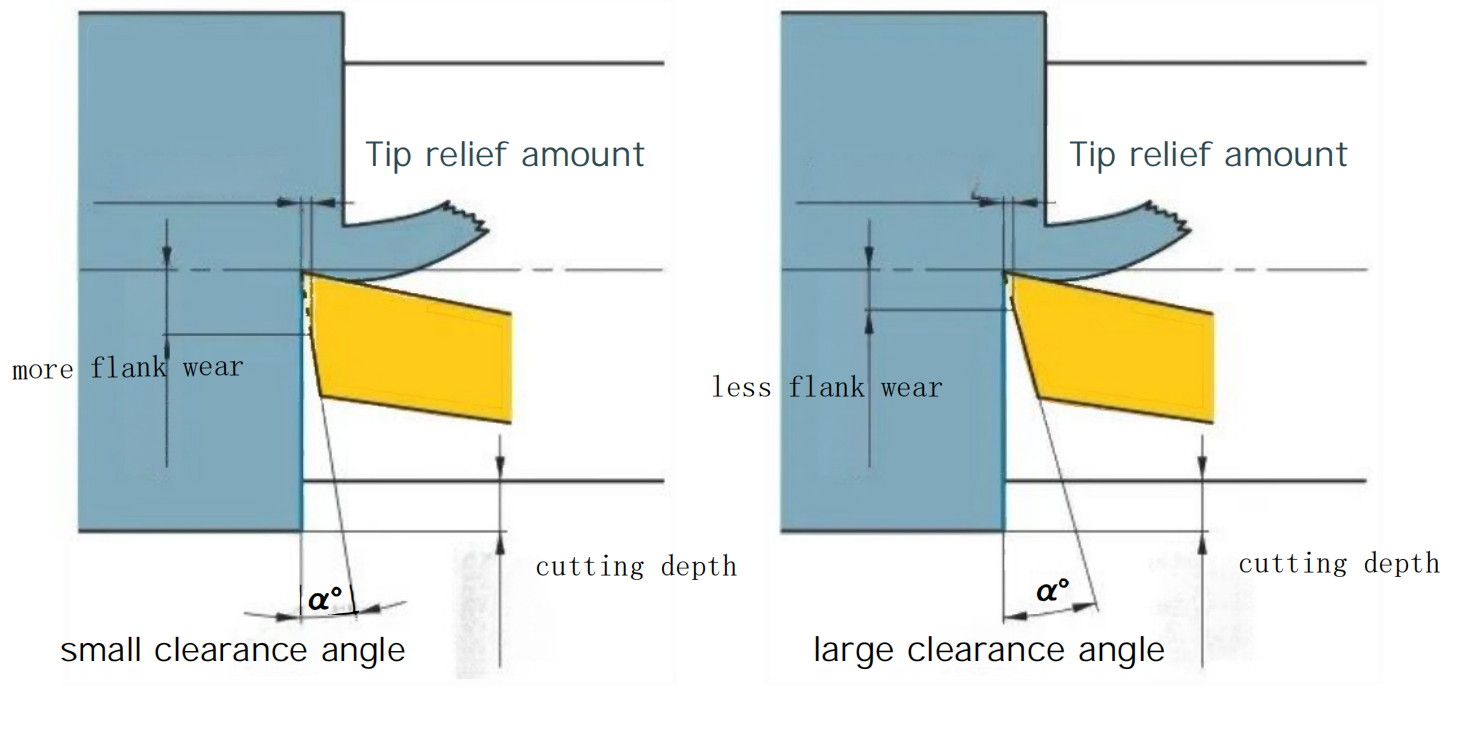

Relief angle size and back tool face wear diagram

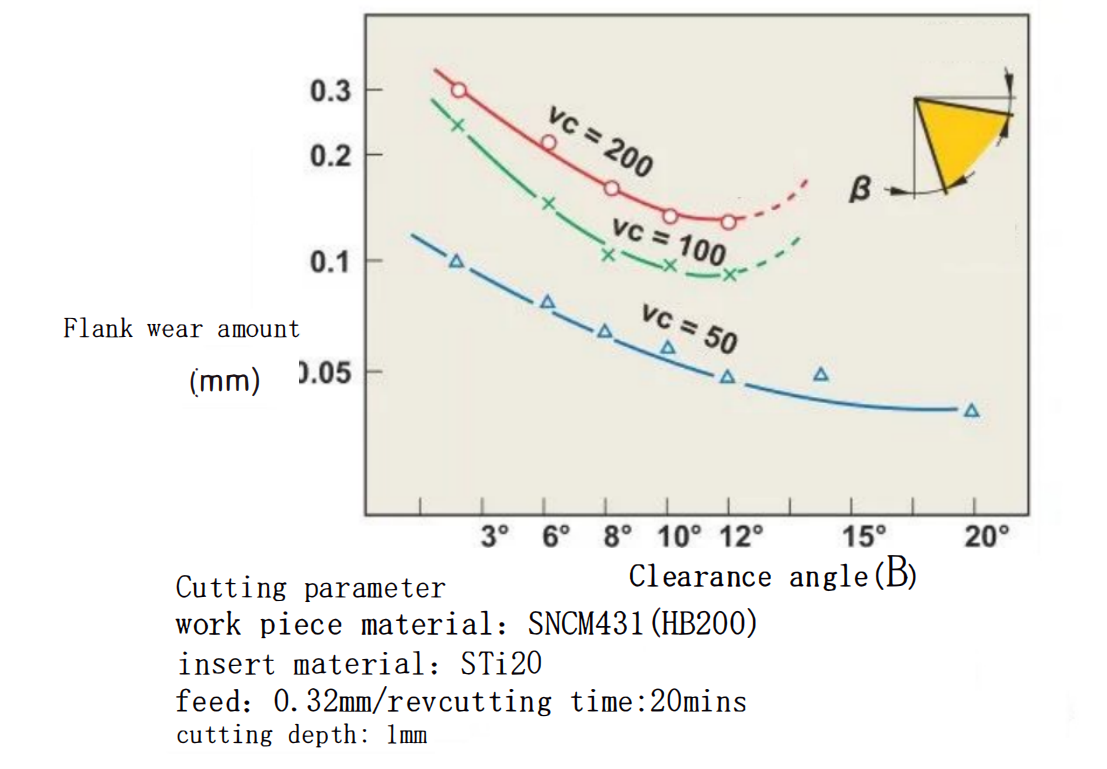

?Influence of relief angle size on turning tools

The relief angle is large, and the rear tool surface is worn less, but the strength of the tool tip is decreased, and the reverse is true when the relief angle is small.

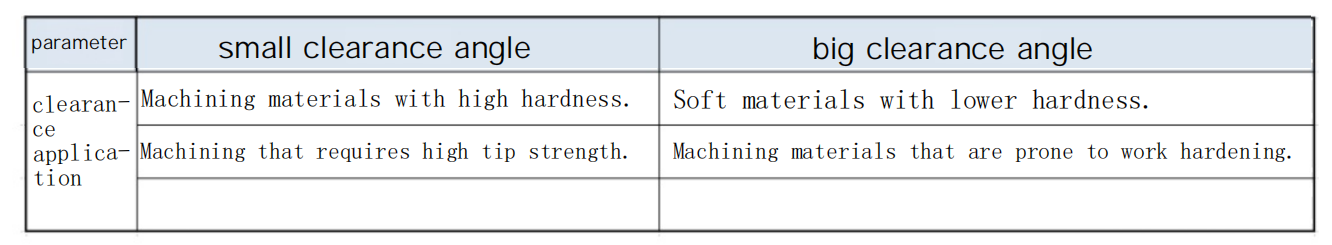

Application of different size relief angle

Secondary rake angle

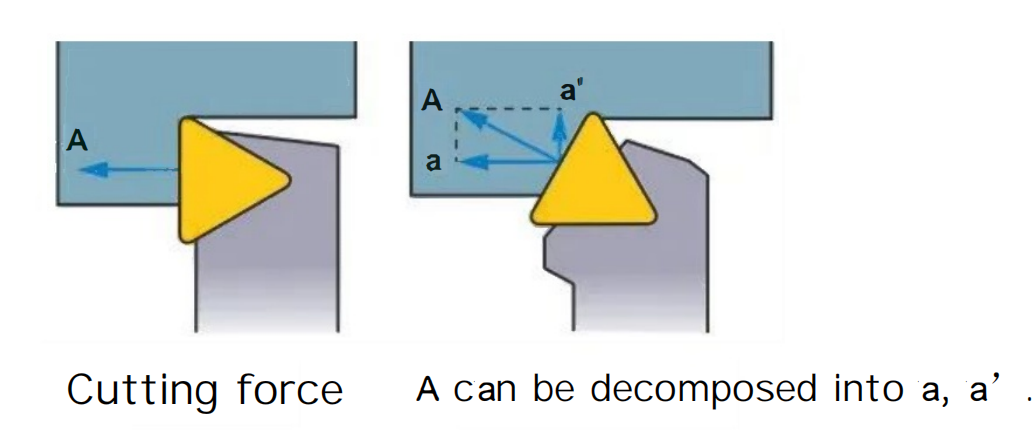

The secondary rake angle affects the mitigation of impact force, the size of the feed force component, the size of the back force component, and the chip thickness.

Impact of the size of the secondary rake angle on cutting

① When the feed rate is the same, a larger secondary rake angle increases the length of contact between the insert and the chip, resulting in a thinner chip thickness. This disperses the cutting force over a longer cutting edge, thereby improving the tool life.

② A larger secondary rake angle leads to an increase in the component force a’, which can cause bending when machining slender workpieces.

③ A larger secondary rake angle results in poorer chip handling performance.

④ A larger secondary rake angle leads to a thinner chip thickness and an increased chip width, making it difficult for the chip to break.

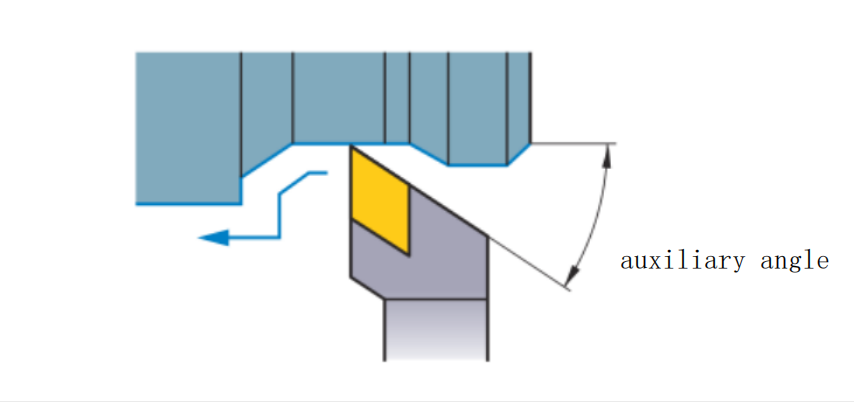

Secondary clearance angle

The angle designed to avoid interference between the machined surface and the tool (secondary cutting edge). It is usually between 5° and 15°.

Impact of the secondary clearance angle

① A smaller secondary clearance angle increases the strength of the cutting edge, but the tool tip is prone to heating.

② A smaller secondary clearance angle increases the back force, which can cause vibration during cutting.

③ For rough machining, a smaller secondary clearance angle is preferable; for finish machining, a larger secondary clearance angle is more suitable.

Inclination Angle

The inclination angle is the angle at which the cutting face is tilted. During heavy cutting, the tool tip at the starting point of the cut bears a significant impact force. To prevent the tool tip from being damaged by this force due to brittleness, an inclination angle for the cutting edge is necessary. In turning operations, it is generally set to 3°-5°;

① When the inclination angle is negative, the chips flow towards the workpiece.

When the inclination angle is positive, the chips are discharged in the opposite direction.

② When the inclination angle is negative, the cutting edge strength increases, but the cutting back force also increases, which can easily cause vibration.

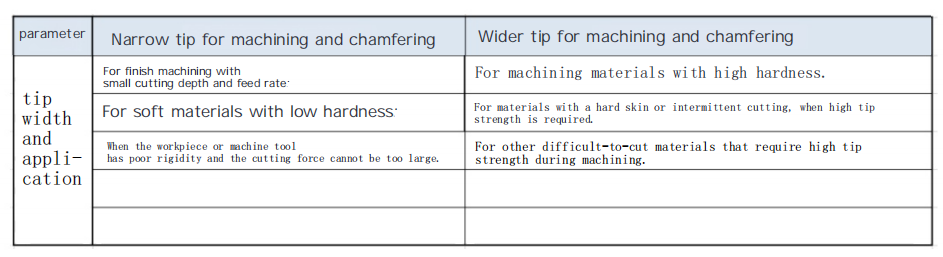

Chamfering and blunting of the cutting edge

Chamfering and blunting of the cutting edge are treatments applied to the cutting edge to ensure its strength. Typically, this involves rounding or chamfering the cutting edge. The chamfer is a narrow band-like surface set along the cutting face or the back face. Usually, the grinding width is half the feed rate.

Influence of cutting edge grinding width on turning tools

① High cutting edge strength, reduced chance of chipping, and improved tool life.

② The wear on the flank face is likely to spread, resulting in a lower tool life. The width has no effect on the wear of the cutting face.

③ Increased cutting force, which can easily cause vibration.

Application of different tip widths

Tip radius

The tip radius is a key factor in turning operations. It has a significant impact on the strength of the tip and the roughness of the machined surface. The specific choice depends on the cutting depth and feed, and it will affect surface quality, chip breaking, and blade strength.

Influence of tip radius

Advantages of a larger tip radius:

① Improved surface roughness.

② Increased blade strength, less prone to chipping.

③ Reduced wear on the front and back of the tool.

Disadvantages of an excessively large tip radius:

① Increased cutting force, prone to vibration.

② Poor chip handling performance.

Application of different tool tip corner radius sizes

In addition, when selecting turning tools and parameters, it is necessary to consider factors such as the nature of the material being machined, the required precision, and the production volume.