What’s the standard tolerance of mold in CNC programming process?

The CNC programming department of the mold factory develops clear processing techniques and standards and performs standardized operations in the production process to improve work efficiency and reduce errors.

1.the former mold

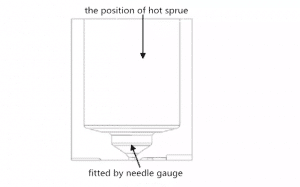

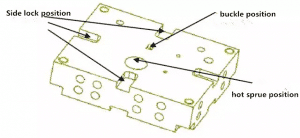

a.Hot position

1 The size required for assembly must be based on the number.

2 Plane: The machining program is based on the number of dimensions, and the CNC operator measures the number according to the tolerance of the drawing size.

3 Side: The machining program is open for compensation. The unilateral side is left with a 0.02mm balance. The operator uses the needle gauge to fit tightly. The tolerance is guaranteed to be within 0.015~0.005mm. The other dimensions are based on the size of the 3D image.

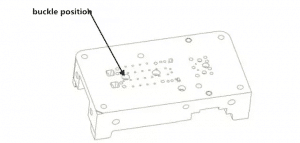

b. Insert buckle

The side of the buckle of the insert shall be processed according to the procedure, and the size shall be determined according to the size, and the depth (Z value) of the buckle of the insert shall be determined according to the number of dimensions, and the operator shall use the calibration gauge to measure the depth, and the tolerance requirement shall be 0.01 mm.

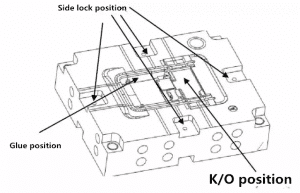

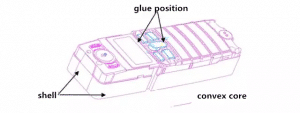

c.Glue size

The finishing procedure for all glue positions requires 0.02 mm on one side (except for special cases), and 0.15 mm on one side with fire pattern requirements for processing EDM lines.

d. Insert and touch the bit

Under normal circumstances, the front mold core is of a proper size, and the rear mold core retains the remaining amount.

e.Side lock position

The bottom depth (Z value) of the side lock position is made to be a standard size, and the side edge machining program of the side lock position needs to be compensated for one side to leave a 0.02 mm test fit. The operator is tightly matched according to the figure size, and the tolerance is guaranteed to be unilateral from 0.015 to 0.005 mm. Inside.

?2.die Pfostenform

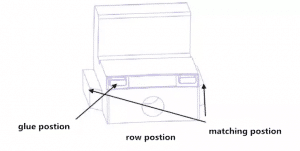

a.Row slot

The depth (Z value) of the row position slot shall be determined according to the number of drawings. The operator shall use the table to measure according to the tolerance of the drawing, and the two sides of the row groove shall be processed according to the drawing size. The program processing shall be compensated for one side and 0.02 mm. The test is equipped with the block gauge, and the tolerance is guaranteed within 0.015~0.005mm on one side.

b.Insert buckle

The side of the buckle of the insert shall be in accordance with the number of drawings, and the depth (Z value) of the bottom shall be in accordance with the number of dimensions. The operator shall use the calibration meter to measure the tolerance to a depth of 0.01 mm.

c.Mold hole position (hiding CORE bit)

The programmer does the light knife program and needs to open the compensation side to leave 0.02mm margin. The opening compensation operator measures according to the number of drawings. The single side is 0.005~0.01mm, which is convenient for assembly.

d. Glue size

All glue position finishing allowances are 0.02mm (except for special requirements).

e. Insert and touch the bit

Under normal circumstances, the rear mold needs to leave more than +0.02~0mm margin. The position of the rear mold with the row position must be determined according to the size of the row, and the position of the mold core after the matching of the row position needs more margin.

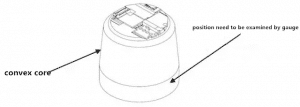

3.the mold convex CORE

a.When roughing, leave 0.5mm margin on one side, and when inserting the frame insert to the bottom to use rough machining CORE, leave 10mm at the bottom straight position for the operator to check if the roughing is loose and need to be quenched. The profiled convex CORE bottom is left straight for 10mm for finishing after quenching.

b.All glue positions are 0.02mm during finishing (except for special requirements), and the position to be inserted and penetrated is +0.02~0mm.

c.Convex CORE shape finishing, when the programmer makes the light knife program, the compensation is the 0.02mm margin on one side, and the operator can measure the tolerance of one side from 0~ –0.005mm according to the number of drawings.

d. The problem of the irregular shape of the mold insert (convex CORE) is detailed in the latter part.

4. row position, insert

a.When receiving the workpiece, the programmer should measure the external dimensions of the workpiece to avoid problems when the number of hits in the middle and the single side. The programmer needs to discuss with the operation group according to the shape of the workpiece, using a secure clamping method and a method of hitting the number. See the latter section for details.

b.The row position and the front and rear mold cores have matching positions, and the row position needs to leave 0.02 mm margin for FIT.

c. All glue positions are 0.02mm on one side (except for special requirements).

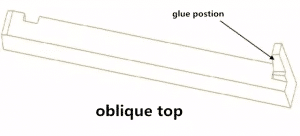

5. oblique top

According to the shape of the workpiece and the operation group, using a secure clamping method, the number of touches, all the glue positions are 0.02mm on one side (except for special requirements). Please add WeChat public number: industrial intelligence (robot info) Ma Yun are paying attention

6. mold processing

a.Mold

(1) The base word (chamfering) on the mold blank drawing should be consistent with the reference on the mold blank. In order to avoid misunderstanding, the machining chaos occurs, and the reference edge faces the direction of itself during programming.

(2) The machining positioning of all the templates establishes the machining coordinates by zeroing the guide hole in the near reference angle.

(3) Z-number hits definition: All templates are processed in forward and reverse directions. The number of touches at the bottom of the mold is zero. For workpieces with special requirements, the programmer needs to explain clearly with the relevant personnel and clearly indicate on the program list. The zero position of the mold embryo.

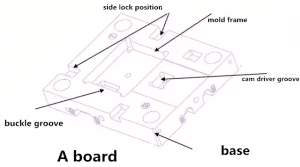

b.A board

(1) When the mold frame is finished, when the bottom of the mold frame is processed, the size must be made according to the size of the paper. The CNC operator uses the calibration of the drawing according to the tolerance of the drawing. The tolerance is +0.01~+0.02mm. The finishing process of the frame edge requires 0.02mm margin for the one side of the compensation. The operator fits the block gauge according to the size of the drawing. Tolerance Guaranteed 0.02 ~ 0.01mm on one side.

(2) The side lock position is made according to the bottom of the figure size. The side block gauge is tightly matched, and the tolerance is guaranteed within unilateral +0.015~-0.01mm.

(3) The bottom of the insert groove should be the number of quasi-sizes, and the side should be tightly tested with the block gauge. The tolerance is guaranteed within unilateral +0.015~ +0.01mm.

(4) The size of the shovel chicken trough and other dimensions are processed according to the plan.

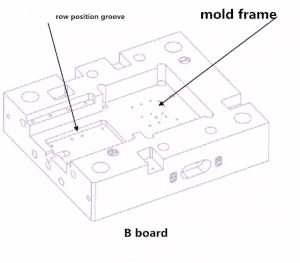

c.B board

(1) Formwork finishing, the number of the standard size of the program processing frame is used, the CNC operator uses the table to measure according to the tolerance of the drawing, the tolerance is +0.01 0mm, the frame edge finishing, the program needs to open the compensation side 0.02mm The margin, the operator needs to use the block gauge according to the size of the figure, the tolerance guarantee – within 0.02~0.01mm on one side.

(2) The depth of the (Z value) at the bottom of the groove of the mold frame should be processed according to the drawing size. The operator uses the calibration meter according to the tolerance of the drawing. The tolerance is +0.01~+0.02mm, and the side program needs to open the compensation sheet. With a 0.02mm test fit, the operator needs to use the block gauge to tightly match the tolerance to unilateral +0.015~+0.01mm.

d Thimble panel:

(1) When the position of the ejector countersunk head is deep processing, the depth needs to be 0.02mm deep, and the operator uses the thousand points card to measure the tolerance, the tolerance is 0.02~0.01mm, and the side of the thimble countersunk head position needs to be processed to the size.

(2) The processing dimensions of the slanting top base assembly position are determined by the bottom of the ejector panel during the processing, and the operator uses the comparison table to measure the number while the side processing size is in place.

(3) The other positions are processed in accordance with the size of the 3D map.

e. thimble bottom plate:

(1) The size position required for the assembly of the insert, the operator needs to be tightly fitted with the block gauge, and the other positions are processed according to the size of the 3D drawing.

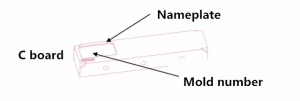

(2) C board: According to the 3D drawing size, the quasi-size is processed, and the working surface and the processing direction are selected by the boring machine group in the positive direction of the A code.

(3) Nameplate: It is required to be carved according to the requirements of 3D drawings.

(4) Upper fixing plate: The size of the mounting position is required for the assembly. The size of the upper fixing plate must be processed at the bottom of the upper fixing plate. The operator needs to use the meter to measure the number, while the side processing needs to open the compensation. 0.02mm, the operator needs to use the needle gauge to ensure that the single side is +0.015~+0.01mm, and other sizes are processed according to the 3D drawing.

(5) Lower fixing plate: There is the size required for the assembly of the insert. The bottom of the lower fixing plate needs to be processed to the quasi-size. The side is required to be tightly packed with the block gauge, and the other dimensions are processed according to the 3D drawing.

f.programming:

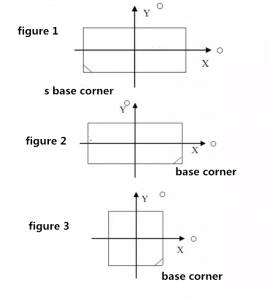

(1) Definition of steel processing coordinates: the rectangular reference is toward the person, and the square reference is toward the lower right corner. In a normal case, all the steel materials are programmed with X and Y points as 0, and the Z value is 0 at the bottom to establish the machining coordinates. (See CNC machining coordinate definition and clamping direction standard drawing 1, 2, 3)

(2)The roughing process is 0.5mm on one side, and the top of the mold is required to be quenched. It is easy to clamp during finishing.

(3) Finishing the bottom of the mold, avoiding the front of the mold, PL, glue position, etc.

(4) Mould tube position: The tube position programming of all front and rear mold cores is 0.01mm small.

(5) Planar PL processing: The program processing should be dimensioned according to the size of the drawing. The operator needs to use the calibration tolerance of the calibration meter to ensure that it is within +0.01~0mm.

(6)The arc surface PL processing, the programmer makes the test procedure, the program list indicates the smooth bottom plane PL, and the light knife processing program makes the standard size.

When the front and rear mold processing coordinates are defined, the rectangular reference is toward the person, and the square reference is toward the lower right corner (0 in the X and Y sides and the bottom is 0 in the Z), as shown in Figure 1, Figure 2, and Figure 3:

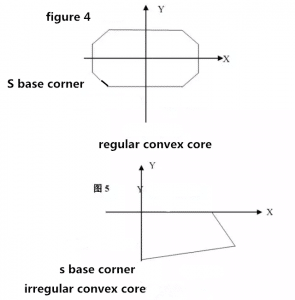

The convex CORE hit number is shown in Figure 4 and Figure 5;

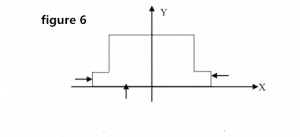

The number of row seats is as shown in Figure 6:

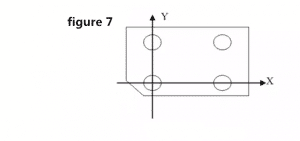

The number of mold collisions is shown in Figure 7: