Heutzutage steigt die Nachfrage nach orthop?dischen Ersatz- und Rehabilitationsger?ten. Zu den medizinischen Komponenten geh?ren künstliche Gelenke und künstliche Platten, St?be und N?gel, die zur Reparatur oder Verst?rkung von K?rperteilen verwendet werden, die durch Unf?lle oder Krankheiten besch?digt wurden.

With the general extension of human life expectancy, more and more elderly people suffer from bone and osteoporosis, which leads to the increasing demand for orthopaedic replacement devices. Global weight gain and obesity trends human bones and joints are under pressure from diameter. Gradually, the lifestyle of most people is changing, from lack of physical exercise to more participation in sports, further increasing the demand for posture exchange. With the development of emerging economies, more and more global research institutions predict that the value of the global orthopedic device market will increase to 50 billion euros ($53 billion) by 2024.

1.Competition promotes the development of cutting tools

In the highly competitive orthopedic parts market, the market share of five major suppliers has expanded by about 85%, and the remaining 200 companies compete for the remaining share. Part processing method. Through the application of new materials, implants become stronger, lighter and can last up to 25 years in the body. In this way, orthopedic equipment is a part of the whole consumer lifestyle market, moving towards personalization; Medical device manufacturers are considering how to customize their products to meet patients’ needs for appearance and other alternatives. Product differentiation has become a key competitive advantage. Therefore, machine tool manufacturers seek to develop solutions to enable them to quickly process parts with complex shapes, while tool manufacturers focus on developing tool technology that can provide higher speed and size. Advanced manufacturing technology solutions include 3D printing technology for processing and advanced cooling technology.

2.Typical medical parts

Orthopaedic instruments include hip and knee parts, artificial elbow and fracture joints, incision rehabilitation equipment, spinal plate and various rehabilitation nails, rods and fasteners. The key requirements of these components are strength, reliability, light weight and biocompatibility.

3.Machining challenges of milling cutters

For bone and knee implants, the most common workpiece material is cobalt chromium alloy, but the use of titanium is also increasing. Typical cobalt chromium alloys include cocr28mo6, etc., and Ti6Al4V titanium alloy is the most commonly used material.

Both materials are biocompatible and very hard, so they are very suitable for the manufacture of orthopedic parts. However, these same characteristics also increase the difficulty of machining alloys. Cobalt chromium alloy has wear resistance, elasticity and poor performance. This alloy may contain hard abrasive components, which will lead to serious wear of cutting and milling cutters and produce tough and continuous chips. Therefore, it is necessary to use the cutting edge groove type with good chip control performance.

Titanium alloy is light and strong. It will harden and twist during processing. On the central cutting edge and face. The high temperature, large cutting force and high friction in the chip channel will lead to the crescent wear and failure of the milling cutter. The material has a minimum modulus of elasticity, which is advantageous in some implant applications, but the material will rebound from the cutting edge during machining, so it is necessary to pay close attention to the sharpness of the cutting tool.

4.Coolant requirements

Materials used to process orthopaedic implants often produce excessive speed and require the use of coolant. However, the use of traditional coolant usually has great restrictions on preventing part pollution. After processing, the traditional coolant needs to be cleaned, which is a time-consuming and costly process. Coolant itself can cause environmental problems in terms of employee health, safety and handling policies. Another cooling technology uses supercritical carbon dioxide (SCCO2) to dry this supercritical SCCO2 as the medium to transport the dry strong conduit to the cutting area.

When CO2 is compressed to 74 bar (1070 psi) at 31 C, it will become supercritical when transported to the cutting area. Although it will not produce low-temperature materials such as liquid nitrogen, supercritical CO2 will expand and form dry ice. In this state, it will fill the container like a gas, but the density is similar to that of a liquid. Therefore, the new coolant solution brings higher cooling efficiency and uses existing systems using high-pressure water / oil, micro lubrication (MQL), liquid CO2 and liquid nitrogen.

5.3D printing parts

Another non-traditional manufacturing technology that is becoming more and more common in the production of orthopedic devices is 3D printing, which uses titanium and cobalt chromium alloy powder to produce complex, nearly net formed parts. In the medical industry, selective laser melting (SLM) technology is used to melt powder and manufacture parts layer by layer. This process allows medical device manufacturers to customize parts with special contours and dimensions for patients. From there, a uniform microporous surface can also be produced, thereby accelerating the parts and body. For finish machining, parts produced by 3D printing retain most of the machining characteristics of the metal they use. However, such parts may need postprocessing to reduce the uneven stress generated during the processing. In addition, due to the near net shape and complex contour of the part, part clamping may be a challenge in the later stage of the process.

6.Replacement of parts

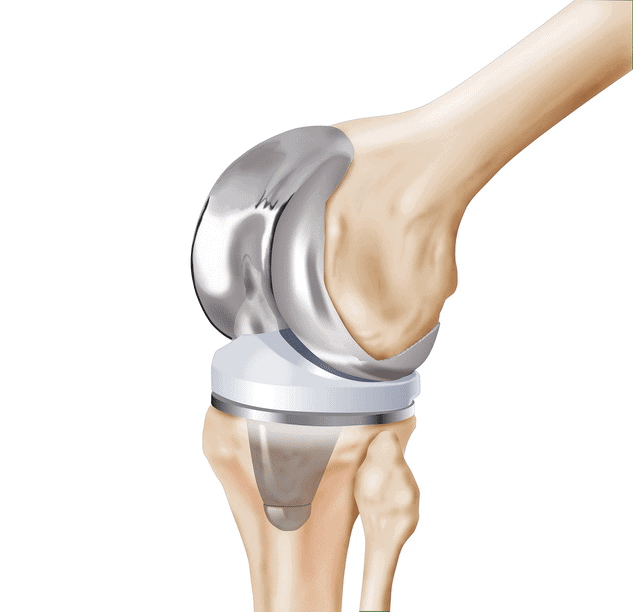

Total knee arthroplasty usually consists of three basic parts: a contour metal (cobalt chromium alloy or titanium) part called the femoral part, which is connected to the end of the femur (thighbone). This part is fixed to the top of the tibia of the lower leg and consists of a short axis or keel to support the aligned surface with protruding edges. The last one consists of plastic bearing inserts between metal parts to enable the joint to move freely.

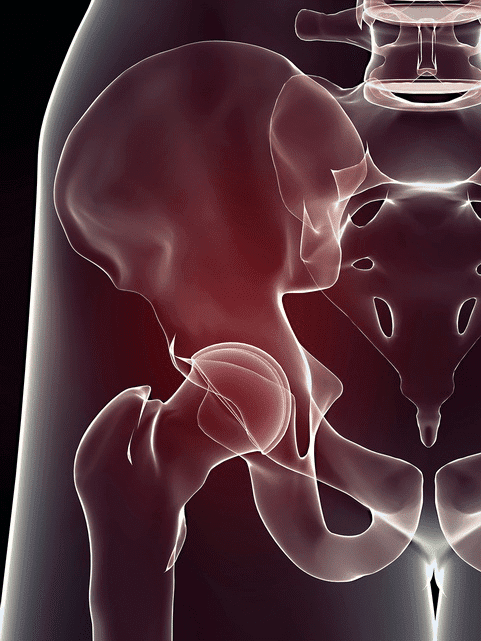

Similarly, hip arthroplasty consists of three main parts: a metal femoral stem with a femoral cap or femoral head at the top and inserted into the top of the femur or hip joint. kit. The Neo alinea bearing insert in the knee joint and the plastic cup in the lumbar joint are usually processed from UHMWPE (ultra high molecular weight polyethylene).

7.Combined manufacturing method

For orthopaedic parts, the surface finish of the plastic joint must be excellent to reduce the expected life of the plastic parts, and the plastic parts must be aligned for 20 years at the same time. For example, when the knee is displaced, the femoral prosthesis and tibial bracket must be absolutely smooth to protect the plastic bearing insert from wear.

Therefore, the manufacturing of orthopaedic components usually needs to be ground after milling operation to achieve a sufficiently fine finish. However, grinding is very time-consuming and will affect the overall manufacturing efficiency and output. In addition, the grinding process will also produce high temperature and stress on the base parts, resulting in dimensional errors of parts and affecting the strength and performance of parts.

In general, advanced cutting machines and high-speed milling strategies can improve the grinding process or replace it in some cases. The purpose of milling is to produce a burr free profile and excellent surface finish, and to achieve specific required surface quality, size and dimensional accuracy. Since the defined surface shape and structure have been realized during milling, the time of post-treatment process (such as polishing (if any)) can be changed alternately. For cutting end mills, the same is true of durable and reliable cutting end mills and maximizing tool life and expectations.

A typical application is to use a ball end mill to process femoral parts made of cast cobalt chromium alloy on a 5-axis milling machine. High speed profiling strategy and high performance end milling cutter eliminate the grinding process. As a result, the machining cycle of each part is 11 minutes, which is 50% shorter than the previous method. The generation of waste parts is eliminated by grinding the hinged surface instead of milling. The integral carbide end mill is made of special cemented carbide materials and hard polished tialsin coating to ensure excellent metal removal rate and smooth cutting effect, so as to obtain excellent surface finish or shortest polishing time.

8.Multiple machining operations

The complex contour of orthopedic parts usually requires the use of several special cutting end mills. For example, some types of bone involve seven machining processes: rough machining, bottom rough machining, bottom finish machining, chamfering and T-groove root cutting. These processes can obtain excellent surface quality and reliable tool performance with minimal manual intervention, so as to ensure the best alignment, lowest cost and highest quality.

In the past, when completing various operations, special cutting and milling cutters were needed to achieve each required contour, size and surface finish. Special cutting machines require a lot of design and development time and cost, and due to their reduced size, their crosslinking time may be prolonged and their availability is limited.

The new approach is to develop and use standardized cutting machines that can be produced efficiently in these applications, and these cutting machines must also retain sufficient size for processing other similar parts in the orthopaedic industry.