Classification of Cutting Fluids

We all know that cutting fluids are mainly divided into two major categories: oil-based and water-based.

Based on their functions, they can be arranged as follows:

Lubricity: Cutting oil > Emulsified fluid, Semi-synthetic cutting fluid > Fully synthetic

Cooling: Fully synthetic > Semi-synthetic cutting fluid > Emulsified fluid > Cutting oil

Rust Prevention: Cutting oil > Water-based cutting fluids (Emulsified fluid, Semi-synthetic cutting fluid, Fully synthetic)

Cleaning: Water-based cutting fluids (Emulsified fluid, Semi-synthetic cutting fluid, Fully synthetic) > Cutting oil

How to Select Cutting Fluids Rationally

There are many types of cutting fluids with different performances. The selection of cutting fluids should be based on factors such as workpiece material, tool material, machining method, and processing requirements.

Rough Machining

1.For rough turning or rough milling of carbon steel workpieces with high-speed steel tools, a low-concentration emulsified fluid (e.g., 3%–5% emulsified fluid) or a synthetic cutting fluid should be used.

2.For rough turning or rough milling of aluminum and its alloys, copper and its alloys with high-speed steel tools, use an emulsified fluid with 5%–7% concentration.

3.When rough turning or rough milling cast iron, due to the presence of graphite, which acts as a solid lubricant to reduce friction, cutting fluids are generally not used. Oil-based cutting fluids may cause the cutting chips and abrasive particles to stick together, acting as abrasives and causing wear to the tools and machine guides.

4.For modern carbide blades, cutting fluids are generally not used because insufficient or uneven cutting fluid flow can cause uneven heating and cooling of the carbide blades, leading to cracking and tool failure.

However, for processing certain high-hardness, high-strength, and poor thermal conductivity special materials (especially heavy cutting), cutting fluids that are sufficient in flow, uniform, and primarily for cooling, such as 2%–5% emulsified fluid or synthetic cutting fluids, should be used to significantly lower the cutting area temperature and extend tool life.

If using a spray application method for the cutting fluid, the cutting effect will be better. When using cutting fluids with carbide tools, continuous application from the beginning to the end is essential to avoid affecting tool life and the quality of the machined surface.

5.For low-speed cutting, where tool wear is mainly due to hard particles, cutting oils focusing on lubrication are preferred. For higher-speed cutting, where tool wear is primarily thermal, cutting fluids with good cooling performance, such as emulsified fluids or water-soluble solutions, should be selected.

????????

Finishing requires high surface roughness and machining accuracy. In addition to considering tool material, workpiece material, and machining methods, cutting speeds should also be considered, and cutting fluids with different properties should be selected.

1.For finishing carbon steel workpieces with high-speed steel tools, the cutting fluid should have good penetration, lubrication, and some cooling properties. At lower cutting speeds (less than 10 m/min), mechanical wear is predominant, so the cutting fluid should have good lubrication and flowability to quickly penetrate the cutting area, reduce friction and adhesion, inhibit chip build-up and burrs, improve workpiece precision, and extend tool life. Use 10%–15% emulsified fluid or 10%–20% extreme-pressure emulsified fluid.

2.For finishing carbon steel workpieces with carbide tools, no cutting fluid may be used, or 10%–25% emulsified fluid or 10%–20% extreme-pressure emulsified fluid can be used.

3.For finishing copper and its alloys, aluminum and its alloys, to achieve a low surface roughness and high quality, 10%–20% emulsified fluid or kerosene can be used.

4.For finishing cast iron, 7%–10% emulsified fluid or kerosene should be used to reduce the surface roughness of the workpiece.

Difficult-to-Machine Materials by applying cutting fluid

Difficult-to-machine materials are those that are harder to process than easier materials, often due to their composition or heat treatment processes. Typically, materials containing elements like chromium, nickel, molybdenum, manganese, titanium, vanadium, aluminum, niobium, tungsten, etc., are considered difficult-to-machine.

These materials have hard particles, high mechanical abrasion, low thermal conductivity, and are prone to chip dispersion. Therefore, cutting fluids for these materials must have high lubrication and cooling properties.

1.For cutting difficult-to-machine materials with high-speed steel tools, use 10%–15% extreme-pressure emulsified fluid or extreme-pressure cutting oil.

2.For cutting difficult-to-machine materials with carbide tools, use 10%–20% extreme-pressure emulsified fluid or sulfurized cutting oil.

Recommendation: Although animal and vegetable oils can be used for difficult-to-machine materials and achieve good cutting effects, they increase costs. Therefore, we should minimize or avoid using animal and vegetable oils as cutting fluids.

Closed or Semi-Closed Cutting Processes

In processes such as drilling, tapping, reaming, and broaching, where chip removal is done in a closed or semi-closed manner, chip removal is difficult, and the heat generated by friction between the tool and chips cannot be dissipated quickly, which can cause burning of the cutting edge and significantly affect the surface roughness of the workpiece. This issue is more prominent when cutting high-hardness, high-strength, and tough materials with significant cold-hardening.

Cutting fluids with good cooling, lubrication, and cleaning properties are needed to reduce heat generated by tool-chip friction and effectively remove chips. For deep hole drilling, broaching, tapping, and reaming, 10%–15% emulsified fluid, 15%–20% extreme-pressure emulsified fluid, mineral oil, or extreme-pressure cutting oil should be used.

Precautions for Using Cutting Fluids

To ensure that cutting fluids achieve the desired effects, the following points should be observed:

Oil-based emulsified fluids must be diluted with water before use.

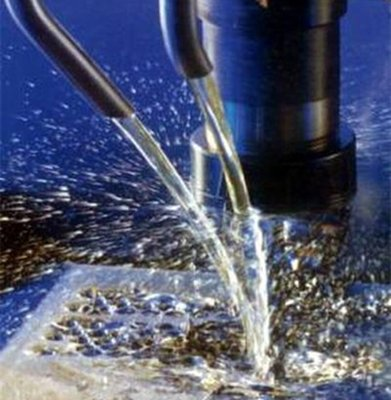

Cutting fluid flow should be sufficient and maintain a certain pressure. The cutting fluid must be applied to the cutting area.

When using cutting fluids with ????? ?????, the fluid must be applied continuously from start to finish to avoid causing cracks in the hard alloy blades due to sudden cooling.

Cutting fluids should be kept clean and impurities should be minimized. Expired cutting fluids should be replaced in a timely manner.

Common Problems and Solutions for Cutting Fluids

| Problem | Cause | Solution |

| High tool?wear?and

short?tool?life |

Poor?lubricationat the?cutting edge,abrasive

????? |

1.Improve lubrication at?the?cutting?edge.

2.Ensure no active substances?in?the?cutting?fluid?cause chemical wear. 3.Increase the cutting fluid?supply?to manage?high?temperatures. |

| Excessive heat

reducing tool?life |

Inadequate cooling | 1.Replace oil-based cutting fluids?with?low-

Miscosity oil-based or water-based cutting fluids. 2.Increase industrial pressure and?flow?rate.?3.Maintain a constant temperature?for?the cutting fluid. |

| Decreasing tool?life?over?time | Loss of?additives?due?to?leakage?or?only water?is

added to water-based?cutting?fluids |

1.For oil-based?fluids,add extreme-pressure?additivesas needed.

2.For water-based fluids,ensurethe concentration?is?correct. |

| Tool adhesion?and

damage?during drilling or?reaming |

Inadequate?lubrication | 1.?Increase fluid?supply volume?and?pressure.?2.Check and adjust dilution ratios?for?water-based?cutting fluids.

3.Use oil-based cutting?fluids with better lubrication?and?anti-adhesion properties |

| Severe adhesion?at?the?cutting?edge

causing dimension?changes |

Severe adhesion?at?the?cutting?edge | 1.Switch from water-based to?oil-based?cutting

fluids?if?adhesion?issevere. 2.Check and?adjust?the effectiveness of active additives?in?oil-?based?cutting?fluids. |

| Poor machining?accuragy | Inadequate fluid?supply?or temperature?control | 1.?Ensure?sufficient?fluid?supply.

2.?Maintain a?stable cutting temperature. 3.For oil-based??fluids,add extreme-pressure additives or?use?better anti-adhesion cutting?fluids |

| Surface?roughness,

tearing,and pulling ofthe machined?surface |

Poo anti-adhesion?properties | 1.?Switch?to?cutting?fluids with better anti-

adhesion properties. 2.?Improve filtration?methods to remove fine?chips. 3.?Improve?fluid supply methods?to?avoid?oil?interruption. |

????

Choosing the right cutting fluid involves understanding its functions and the specific requirements of the machining process. By considering factors like material properties, cutting conditions, and process specifics, you can select the most suitable cutting fluid to achieve optimal performance in different machining scenarios.