Automotive lightweight trend accompanied by aluminum alloy

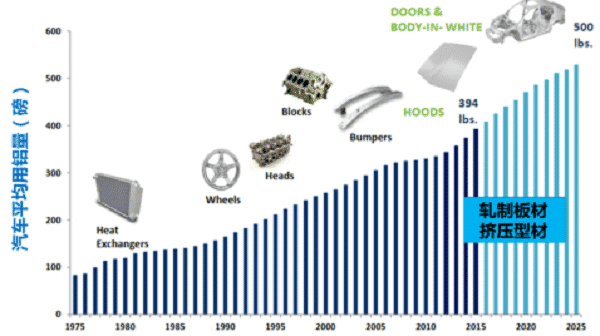

Figure 1. Changes in the average amount of aluminum used in European cars

Today, the term “l(fā)ightweight” has evolved from the terminology of the automotive industry to the high-frequency vocabulary in media news. In “Made in China 2025”, light weight has also been regarded as an important direction for the development of the automobile industry. To put it simply, light-weighting is to reduce the weight of the vehicle as much as possible while ensuring the strength and safety of the vehicle, thereby improving the vehicle’s power, reducing fuel consumption and reducing exhaust pollution. In recent years, as environmental protection and energy conservation requirements have become stricter, automobile lightweighting has become an unstoppable trend in the development of the world’s automobiles. According to the European Aluminum Association, every 100kg of car quality can save 0.6L of fuel per 100 kilometers and reduce CO2800-900g. Aluminum has a density of only 1/3 of steel and has good plasticity and recovery. It is an ideal lightweight material for automobiles. During the first oil crisis of the 1970s, in the face of rising oil prices, automakers around the world tried to use aluminum alloys to make steel radiators, cylinder heads and bumpers. Fuel efficiency. Since then, the proportion of aluminum alloys in automobiles has been increasing. According to research data released by the famous consulting firm Ducker Worldwide, the average aluminum consumption in European cars has tripled since 1990, from 50kg to the current 151kg, and will increase to 196kg in 2025.

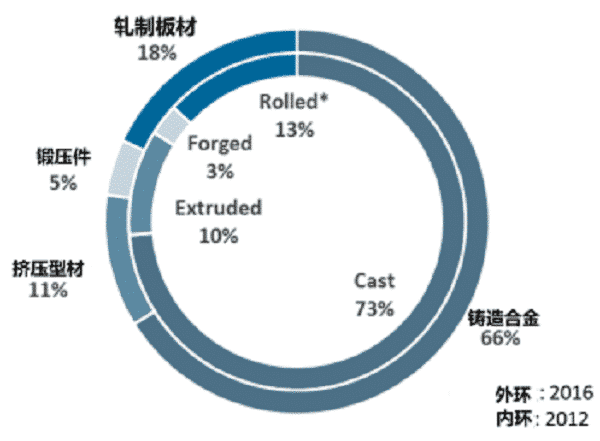

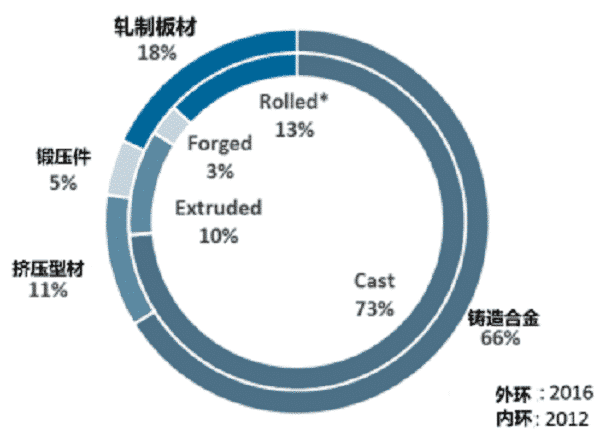

Figure 2. European automotive aluminum (140kg) distribution ratio (2012 data)

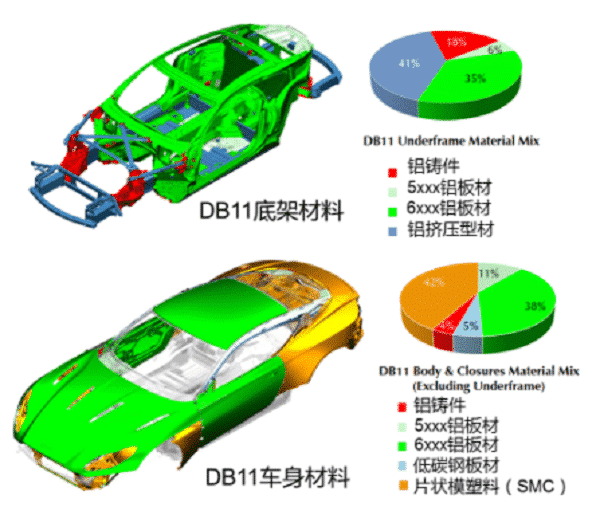

At present, the trend of lightweight vehicles is becoming more and more fierce, and aluminum alloys are widely used in hubs, engines, radiators, and oil pipes. The body quality accounts for about 40% of the total mass of the car. For the weight reduction of the whole car, the weight of the car body plays an important role. According to the 2016 European Body Conference (EuroCarBody 2016), the application rate of aluminum alloy has reached more than half of the quality of some high-end models of body-in-white (that is, the body that is welded but not painted). For example, Aston Martin’s DB11 aluminum alloy application rate is as high as 86.1%, the second generation Honda NSX (Acura NSX) is 79.0%, and the 5th generation Land Rover Discovery is 62.9%. However, the application of aluminum alloys on the body of ordinary models is still relatively small. According to data from the well-known consulting firm Ducker Worldwide, the penetration of aluminum alloy panels in car bodies was only 4% in 2015. Today, all-aluminum bodywork is still a technology at the tip of the pyramid, and it is only used on some high-end models. Lightweight body is an important research topic in the development of lightweight manufacturers.

Figure 3. Aston Martin DB11 aluminum alloy application distribution

2. Main types of aluminum alloy for vehicles

At present, aluminum alloys for automobiles can be basically divided into die-cast aluminum alloys and deformed aluminum alloys, among which die-cast aluminum alloys are mainly used, accounting for about 66%. The deformed aluminum alloy can be further divided into rolled sheet (18%), extruded sheet (11%) and a small amount of forged parts (5%). It is worth noting that although the cast aluminum alloy in 2016 is still the main form of automotive aluminum alloy, its share has dropped by 8 percentage points compared with 2012. On the contrary, due to the development of lightweight body, the share of rolled sheet increased significantly from 13% in 2012 to 18% in 2016. At the same time, the share of extruded profiles and forgings does not change much.

Figure 4. Comparison of European automotive aluminum alloys in 2016 and 2012

a.Cast aluminum alloy

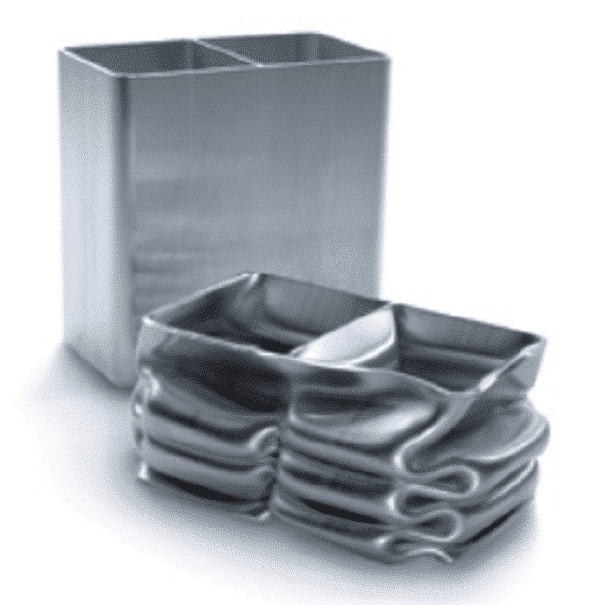

Cast aluminum alloy is the most widely used type of aluminum alloy in most automobiles, and is widely used in structural parts such as wheels, engine parts, underframes, shock absorber brackets and space frames. In the automotive industry, cast aluminum alloy wheels are the fastest-growing parts with higher aluminizing rates. At present, most of the aluminum alloy wheels are manufactured by low-pressure casting using A356 alloy, and some high-grade wheels are manufactured by extrusion casting, die forging or spinning. Both the cylinder block and the cylinder head of the engine require good thermal conductivity and corrosion resistance, which is the advantage of the aluminum alloy. At present, a large number of domestic and foreign cars use aluminum cylinder blocks and cylinder heads, but cast iron is still used in some places where high strength and high resistance are required. In recent years, the development of new Al-Si-Cu-Mg-Fe alloys and the development of corresponding casting technologies have enabled aluminum alloy castings to achieve higher performance, further promoting the application of aluminum alloys in engine components, including diesel engines. Casting methods for cylinder heads are also diverse, such as gravity casting and low pressure casting. In addition, cast aluminum alloys have been widely used in structural parts such as shock absorber brackets, electric vehicle battery packs, and structural cabinets. Since these components are mostly thin-walled members with complicated shapes, they are often manufactured by a high-pressure casting method using an Al-Si alloy.

b.deformed aluminum alloy

Compared with cast aluminum alloys, the average application share of deformed aluminum alloys in automobiles is still small. According to a survey by Ducker Worldwide, deformed aluminum alloys accounted for only 34% of automotive aluminum alloys in 2016 (18% for rolled sheets, 11% for extruded profiles, and 5% for forgings). However, in some high-end models that use an all-aluminum body, the share of deformed aluminum is much higher than that of cast aluminum. At present, the industry has invested heavily in the research and development and application technology of deformed aluminum alloys including all-aluminum body technology, and its proportion has rapidly increased. Ducker Worldwide predicts that due to the rapid development of aluminum alloy body technology, the application of deformed aluminum alloys (especially rolled sheets) in automobiles will usher in rapid growth (as shown in Figure 1).

The automotive deformed aluminum alloy mainly includes a 5xxx series (Al-Mg type), a 6xxx type (Al-Mg-Si type), and a small amount of 2xxx series (Al-Cg type) and 7xxx type (Al-Zn-Mg type). Among them, the 5xxx series alloy can not be heat-treated and strengthened, and the molding property is excellent. However, after forming, the yield point is prolonged and the surface is wrinkled, which affects the appearance quality of the product, and therefore is mainly used for a complicated shape such as an inner panel. The 6xxx series alloy can be heat-treated and strengthened by the solid solution of Mg and Si and the aging precipitation of Mg2Si phase. The strength after coating and drying is improved, and the dent resistance is high, which is suitable for the requirements of outer panel and body frame. Strength, rigidity. Except for rolled sheet, extruded profiles are also important automotive deformed aluminum alloys, generally suitable for structural parts of equal section, such as bumper, energy absorbing box, front section of front longitudinal beam, sill, rear section of rear longitudinal beam. The medium strength 6xxx is the main material for extruded profiles due to its high extrusion rate and surface quality, as well as age hardening properties during extrusion. High-strength 7xxx aluminum alloys are also used to produce extruded profiles where high strength is required. At the same time, in order to improve the impact strength, the profiles of the profiles are mostly “mouth”, “day” and “mesh”.

Figure 5. “Day” type energy absorbing box for extruded profiles (before the collision on the left and after the collision on the right)

3. The challenge and development direction of automotive aluminum alloy

Aluminum alloys play an important role in the car lightweight wave, but they also face important challenges. In fact, lightweighting is not just about reducing weight, but about balancing the performance, safety, cost, and weight of the vehicle. At present, the core resistance of automotive aluminum alloys is still high cost, which makes the application of all-aluminum body only limited to high-end models and temporarily unable to expand to a large number of economic models. The performance limitation of aluminum alloys is also an important factor that restricts its development. On some parts, it still cannot replace steel. At the same time, the connection technology of aluminum alloys, especially the multi-material joining technology of cast iron-aluminum, steel-aluminum, magnesium-aluminum, etc., is also a major factor in the application of aluminum alloys in automobiles. Audi’s new A8 D5 “discarded” the all-aluminum body that has been in use for more than 20 years, and used a high-strength steel with considerable weight. Affected by this, the D5 model gained 51KG more than the previous model, but the body’s torsional rigidity has increased by 24%, the safety has been greatly enhanced, and the cost has been greatly reduced.

Under the Sixth Framework Programme, the EU organized 38 units in nine countries and regions in 2004-2009 to implement the super-light body joint research and development project (SuperLight-Car). The experience of this project shows that the further development of automotive aluminum alloys should focus on the development of new high-performance alloys and new production technologies. R&D work also needs to integrate resources. The automakers will take the lead in cooperating with raw materials, parts suppliers and related scientific research institutions to jointly explore advanced lightweight technologies and promote the establishment of a lightweight industrial chain.

Main reference materials:

1.Hirsch, J. (2014). Recent development in aluminium for automotive applications. Transactions of Nonferrous Metals Society of China, 24(7), 1995-2002.

2.Hirsch, J. (2011). Aluminium in innovative light-weight car design. Materials Transactions, 52(5), 818-824.

3. Lahaye, C., Hirsch, J., Bassan, D., Criqui, B., Sahr, C., Goede, M., & Volkswagen, AG (2008). Contribution of aluminium to the multi-material light- Weight BIW design of superlight-car [C]. In HIRSCH J, SKROTZKI B, GOTTSTEIN G. Proceedings of the 11th International Conference on Aluminium Alloys. Weinheim: WILEY-VCH Verlag GmbH & Co. KGaA (pp. 2363-2373).

4.Aluminum Content in Cars. Ducker Worldwide, https://www.ducker.com/

5.Aluminium in cars, unlocking the light-weighting potential. European Aluminium Association, https://www.european-aluminium.eu/

6.Goede, M., Stehlin, M., Rafflenbeul, L., Kopp, G., & Beeh, E. (2009). Super Light Car–lightweight construction thanks to a multi-material design and function integration, European Transport Research Review, 1: 5-10.

7.2016 European Body Conference (EuroCarBody) information.