After a long period of development in 1860, cutting fluid began to be widely used in vehicle, planer, grinding, gear processing and thread processing. With the development of cutting fluid, vegetable oil, edible oil, water and so on are gradually formed. I am often asked to recommend cutting fluids for metal processing equipment. In fact, choosing the right cutting fluid is very simple. In order to select the best oil, you need to collect some basic information about the selection criteria. For simplicity, you need to know the workpiece materials, basic machine types, tool details, and factory processes used.

What kinds of cutting fluids are common?

In order to meet different processing requirements, there are many kinds of cutting fluids, which can be divided into water-based cutting fluids and oil-based cutting fluids according to chemical composition and state.

Generally, the cutting fluid diluted by water is called a water-based cutting fluid, and the cutting fluid used without water dilution is called oil-based cutting fluid.

- Water-based cutting fluids are mainly cooled and have poor lubricity. The commonly used water-based cutting fluids are a rust-proof emulsifier, rust-proof lubricant emulsifier, extreme pressure emulsifier, and microemulsion.

- Oil-based cutting fluids are mainly lubricating but have poor cooling and cleaning effects. The commonly used oil-based cutting fluids are pure mineral oil, fat oil + mineral oil, inactive extreme pressure cutting fluids, active extreme pressure cutting fluids, etc.

Next, I have arranged a table to introduce the types and characteristics of cutting fluids in detail.

| category | type | composition | characteristics |

| water soluble | Antirust Emulsion | It is composed of mineral oil, emulsifier, rust inhibitor, etc. The content of mineral oil is about 50%~80% in water to form an oil-in-water emulsion. | Compared with oil-based cutting liquid, the advantage of emulsifier is a good cooling effect. Generally, the water solution diluted by 5%~10% has a lower cost and is safe to use. The biggest disadvantage of emulsifier is its poor stability, susceptibility to bacteria and molds, and short use period. |

| Rust-proof lubricant emulsion | Contains animal and vegetable fats or long-chain fatty acids (such as oleic acid). A small amount of sodium carbonate, sand or sodium benzoate can be added to the emulsion to prolong the service life. | It has good lubricity, but the disadvantage is that these animal and vegetable fats or long-chain unsaturated fatty acids are easy to be decomposed by microorganisms and fungi, and the use cycle is very short. | |

| Extreme Pressure Emulsion | It contains oil-soluble sulfur, phosphorus and chlorine extreme pressure additives. | It has strong extreme pressure and slippery property. It can be used for Equal-Weight cutting such as achievement, broaching and banding. It can also be used for processing difficult-to-cut materials such as stainless steel and heat-resistant alloy steel. | |

| oilbased | Fat-proof oil (or oily additive) +mineral oil | Commonly used fat oils are rapeseed oil, soybean oil, lard and so on. | Oil-proof grease has strong adsorptive property to metal surface and good lubrication performance. Its disadvantage is that it is easy to oxidize and deteriorate, and forms a mucous film (yellow gun) which is difficult to clean on the surface of machine tool. It is generally used in precision cutting such as finish turning soft rod, gear hobbing, gear making and so on. |

| Active Extreme Pressure Cutting Fluid | It is made of mineral oil and sulfur extreme pressure additive with strong reactivity. | It has good sintering resistance and very long lubricity, can improve the service life of cutting tools under high temperature and high bed conditions, and has strong control ability for cutting tool debris. It is mostly used for cutting materials which are easy to gnaw and difficult to machine. | |

| Inactive extreme pressure cutting fluid | It is composed of mineral oil and inactive extreme pressure additives. | Extreme pressure lubrication is good for non-ferrous metal corrosion. Easy to use, widely used in a variety of processing environments |

So, back to the initial subject, how to choose cutting fluid for different tool materials

Understanding the types and characteristics of cutting fluids, which four factors need attention?

Workpiece materials

Some metals are more difficult to process than others. Stainless steel, foreign alloys, and very hard metals require high performance cutting fluids. Other metals, such as brass and aluminum, are easily processed with general-purpose oils.

If hard and low machinability metals are involved, high addition cutting fluids with excellent extreme pressure (EP) and welding resistance are required. In most cases, these oils contain active sulfur and chlorine to protect tools and ensure good parts finish.

For brass, aluminum, many carbon and low alloy steels, cutting fluids containing lubricant additives, friction modifiers, and low extreme pressure/welding resistance are sufficient. These oils are usually formulated with sulfurized fats (inactive) and/or chlorinated paraffins. Active cutting fluids (containing active sulfur) should not be used for brass and aluminum because they can contaminate or stain finished parts. Oils for brass and aluminum are often referred to as “non-dyeing” oils.

Basic Machine Types

The type of machine will also determine the characteristics of some cutting fluids. For example, there is serious cross-contamination between lubricating oil and cutting fluid of screw machine. Therefore, these machines often use dual-purpose or triple-purpose oils that can be used in lubrication boxes, hydraulic systems and cutting fluid pools.

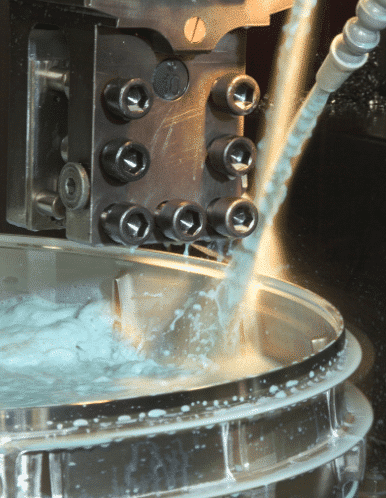

Lapping machines, gun drills, and deep hole drills require lighter viscosity oils to achieve high-speed cooling, good chip and chip washing, and no foam production through tool delivery and high-pressure applications. Manufacturers of CNC raw equipment may limit cutting fluids because they may not be compatible with machine parts such as seals. Centerless grinders may require a harder fluid than surface grinders.

Be ready to discuss plant equipment when suppliers are asked to provide suggestions for metalworking fluids.

Tool details

Certain cutting fluid additives cannot be used effectively with specific coatings, and incorrect abrasive oils can lead to wheel loads and other problems. If you spend the extra money on carbide tools, cobalt coatings or cubic boron nitride (CBN) grinding wheels, it makes sense to choose a cutting fluid that maximizes performance and economic returns.

Cemented carbide tools:

Cemented carbide is composed of tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC) and 5%-10% cobalt. Its hardness is much higher than that of high-speed steel. Its maximum allowable working temperature can reach 1,000 C. It has excellent wear resistance and can reduce the bonding phenomenon between chips when processing steel materials.

Because of the good red hardness of cemented carbide cutting tools, dry cutting is usually used in the processing of general materials without cutting fluid.

| 1 | In dry cutting, the high-temperature rise of the workpiece makes the workpiece easy to produce thermal deformation, which affects the workpiece processing accuracy. Therefore, when choosing cutting fluid, the sensitivity of cemented carbide to sudden heat should be considered, so that the tool can be uniformly heated as far as possible, otherwise, it will lead to edge collapse. |

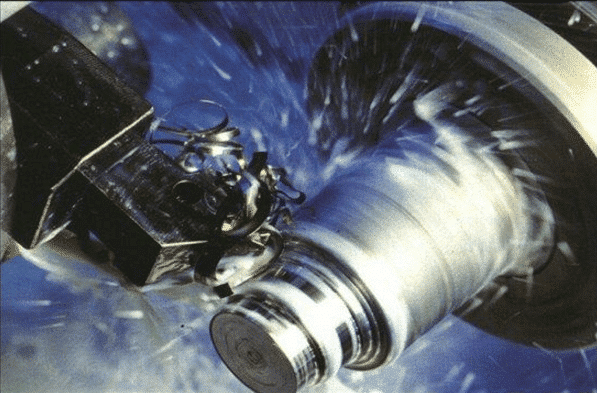

| 2 | For high-speed cutting, the cutting area should be sprayed with large flow cutting fluid to avoid tool thermal unevenness and edge collapse and to reduce soot pollution caused by evaporation due to excessive temperature. |

Generally, the thermal conductivity of oil-based cutting fluids is poor, and the risk of tool sudden cooling is smaller than that of water-based cutting fluids. Therefore, oil-based cutting fluids containing anti-wear additives are generally suitable. When cutting with cutting fluid, attention should be paid to the uniform cooling of the tool. It is better to pre-cool the tool before starting the cutting.

Ceramic cutting tools:

This material is sintered by alumina, metal, and carbide at high temperature. Its high temperature wears resistance is better than that of cemented carbide. Therefore, dry cutting is generally used.

Considering uniform cooling and avoiding excessive temperature, water-based cutting fluid is often used, but it is better to pour continuously and sufficiently without interruption.

Diamond cutting tools:

Diamond cutting tools have very high hardness, generally using dry cutting. In order to avoid excessive temperature, water-based cutting fluids are used in many cases, just like ceramics.

High Speed Steel Cutting Tools

This material is high-grade alloy steel based on chromium, nickel, tungsten, molybdenum, and vanadium (some also contain aluminum). Its heat resistance is obviously higher than that of tool steel, and the allowable maximum temperature can reach 600 C. It has high toughness and is suitable for complex geometry workpiece and continuous cutting, and high-speed steel has good machinability and price acceptability.

Because of the poor redness and hardness of high-speed steel cutting tools, cutting fluid is needed in use.

| 1 | Oil-based cutting fluids or emulsifiers are recommended for low and medium speed cutting. |

| 2 | In high-speed cutting, water-based cutting fluid is suitable because of its high calorific value. |

| 3 | Extreme pressure emulsifier or cutting fluid are used in finishing to reduce friction, improve surface quality and accuracy, and prolong tool life. |

If oil-based cutting fluid is used, there will be more oil mist, which will easily cause workpiece burns, reduce the quality of processing and increase tool wear. In addition, extreme pressure water solution or extreme pressure emulsifier is recommended for rough processing.

Factory Technology

Cutting fluids must meet your production requirements without causing problems in downstream activities. Fluids most suitable for mechanical processing applications may cause serious problems in cleaning, painting, packaging or treatment. A review of downstream processes, including storage and transportation, will determine the key requirements that metalworking fluids must meet. Identifying these requirements early in the selection process will avoid wasting time and money in testing and installing the wrong fluids.

Anyway, cutting fluids can affect your equipment, personnel, environment, and business reputation. If you take the time to choose carefully, buy quality products from reputable suppliers, and seek competent technical advice, you will get considerable returns. Correct selection will improve product quality, reduce manufacturing costs and avoid costly downstream problems.

Now you must know how to select premium cutting lubricant per your requirement. subscribe to us now to get more alike blogs that are helpful to your project.