Cemented carbide is the most widely used high speed machining (HSM) tool material. This kind of material is produced by powder metallurgy process, which is composed of cemented carbide (usually tungsten carbide WC) particles and soft metal bond. At present, there are hundreds of different components of WC based cemented carbides, most of them use Cobalt (CO) as binder, nickel (Ni) and chromium (CR) are also commonly used binding elements, in addition, some other alloy elements can be added.

Grades of simple cemented carbide

These grades used in metal cutting usually contain 3% – 12% cobalt (weight ratio). The size range of WC grains is usually 1-8 μ M. As with other grades, the hardness and transverse fracture strength (TRS) of WC can be improved by reducing its particle size, but its toughness can be reduced. The hardness of single type brand is usually between 89-93.5hra, and the transverse fracture strength is usually between 1.2-2.4mpa (175-350ksi). There may be a large number of recycled raw materials in the powder of this brand.

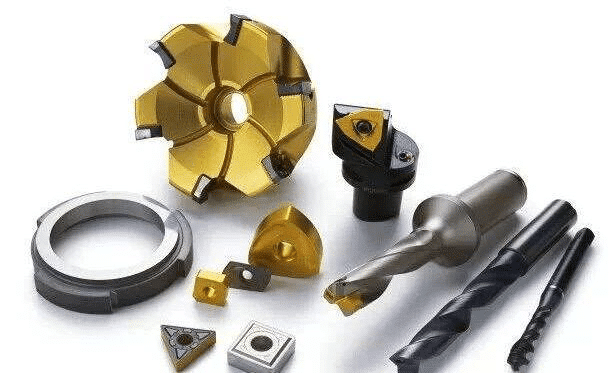

Pure brand can be divided into C1-C4 in C brand system and K, N, s and H brand series in ISO brand system. Simple brands with intermediate characteristics can be classified as general brands (such as C2 or K20), which can be used for turning, milling, planing and wok cutting; brands with smaller grain size or lower cobalt content and higher hardness can be classified as finishing brands (such as C4 or K01); brands with larger grain size or higher cobalt content and better toughness can be classified as rough processing brands (such as C1 or K30).

The tool made of pure type can be used for cutting cast iron, 200 and 300 series stainless steel, aluminum and other non-ferrous metals, high temperature alloy and hardened steel. These grades can also be used in the field of non-metal cutting (such as as as rock and geological drilling tools). The grain size of these grades ranges from 1.5 to 10 μ m (or larger), and the cobalt content is 6% – 16%. Another non-metal cutting use of pure cemented carbide grades is to make dies and punches. These grades usually have medium-sized grain size and cobalt content of 16% – 30%.

Grades of microcrystalline cemented carbide

These brands usually contain 6% – 15% cobalt. In the process of liquid phase sintering, the addition of VCC and / or chromium carbide can control the grain growth and obtain the fine grain structure with the grain size less than 1 μ M. This kind of fine grain grade has very high hardness and transverse fracture strength above 3.45mpa (500ksi). The combination of high strength and enough toughness makes it possible for this kind of tool to adopt a larger positive rake angle, so as to reduce cutting force and produce thinner chips by cutting instead of pushing metal materials.

Through the strict quality identification of various raw materials in the production of grade cemented carbide powder, and the strict control of sintering process conditions, to prevent the formation of abnormal large grains in the material microstructure, we can obtain appropriate material properties. In order to keep fine and uniform grain size, recycled powder can be used only when the raw material and recycling process can be fully controlled and extensive quality inspection can be carried out.

Microcrystalline brand can be classified according to m brand series in ISO brand system. In addition, other classification methods in C brand system and ISO brand system are the same as that of pure brand. Microcrystalline grade can be used to make tools for cutting softer workpiece materials, because the surface of such tools can be machined very smooth, and can maintain extremely sharp cutting edge.

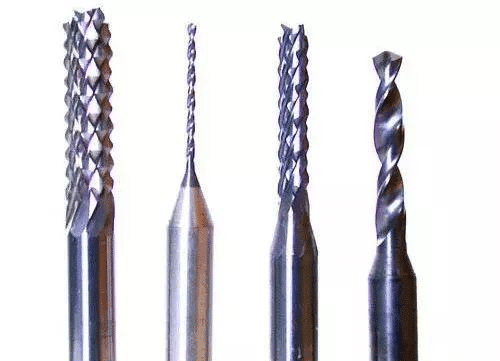

Microcrystalline tools can also be used to process nickel base superalloys because they can withstand cutting temperatures up to 1200 ℃. For the processing of superalloys and other special materials, the use of microcrystalline grade cutters and ruthenium containing pure grade cutters can improve their wear resistance, deformation resistance and toughness at the same time. Microcrystalline grades are used to create a rotating tool (such as a drill bit) that will produce shear stress. One kind of bit is made of cemented carbide of composite grade. The cobalt content in the material is different in the specific part of the same bit, so the hardness and toughness of the bit are optimized according to the processing needs.

Grades of cemented carbide

These grades are mainly used for cutting steel parts, with cobalt content of 5% – 10% and grain size of 0.8-2 μ M. By adding 4% ~ 25% titanium carbide (TIC), the tendency of WC diffusion to the steel chip surface can be reduced. By adding no more than 25% tantalum carbide (TAC) and Carbyne (NBC), the strength, wear resistance and impact resistance of the tool can be improved. The addition of such cubic carbide can also improve the red hardness of the tool, which is helpful to avoid thermal deformation of the tool in heavy load cutting or other processes where the cutting edge will generate high temperature. In addition, titanium carbide can provide nucleation position and improve the distribution uniformity of cubic carbide in the workpiece.

Generally speaking, the hardness range of alloy type cemented carbide is 91 ~ 94HRA, and the transverse fracture strength is 1 ~ 2KPa (150 ~ 300ksi). Compared with the pure type, the wear resistance of the alloy type is worse and the strength is lower, but the adhesive wear resistance is better. Alloy grades can be divided into C5-C8 in C grade system and P and M grades in ISO grade system. Alloy type grades with intermediate properties can be classified as universal grades (such as C6 or P30), which can be used for turning, tapping, planing and milling. The highest hardness grades can be classified as finishing grades (such as C8 and P01) for finishing and keying. These grades usually have smaller grain size and lower cobalt content to obtain the required hardness and wear resistance. However, similar material properties can be obtained by adding more cubic carbides. The grades with the best toughness can be classified as rough machining grades (such as C5 or P50). These grades usually have medium-sized particle size and high cobalt content, and the addition of cubic carbide is less, so as to obtain the required toughness by inhibiting crack growth. In intermittent turning, the cutting performance can be further improved by adopting the cobalt rich grade with high cobalt content on the surface of the cutting tool.

Alloy grades with low titanium carbide content are used for cutting stainless steel and malleable cast iron, but also for processing non-ferrous metals (such as nickel base superalloys). The grain size of these brands is usually less than 1 μ m, and the content of cobalt is 8% – 12%. Grades with higher hardness (such as M10) can be used for turning malleable cast iron, while grades with better toughness (such as M40) can be used for milling and planing steel parts, or for turning stainless steel or super alloy.

Alloy type cemented carbide grades can also be used for non-metal cutting purposes, mainly for the manufacture of wear-resistant parts. The grain size of these brands is usually 1.2-2 μ m, and the cobalt content is 7% – 10%. In the production of these brands, a large proportion of recycled raw materials are usually added, so as to obtain high cost-effectiveness in the application of wear-resistant parts. Wear resistant parts need to have very high corrosion resistance and high hardness. These properties can be obtained by adding nickel and chromium carbide in the production of such brands.

In order to meet the technical and economic requirements of tool manufacturers, cemented carbide powder is the key element. The powder designed for the machining equipment and process parameters of the tool manufacturer can ensure the performance of the finished workpiece, and lead to hundreds of cemented carbide brands. The recycling characteristics of cemented carbide materials and the ability to work directly with powder suppliers enable tool manufacturers to effectively control their product quality and material costs.