What are the common types of chucks of NC machine tools?

1. various chucks

The chuck includes three jaw self centering chuck, hydraulic power self centering chuck, adjustable jaw chuck and high-speed power chuck (up to 100000 R / min).

2. Tailstock

The tailstock of NC lathe plays an auxiliary supporting role for the workpiece during machining.

3. Dividing head

NC indexing head is a common accessory of NC milling machine and machining center. Its function is to make rotary indexing or continuous rotary feed movement according to the signal or instruction of the control device, so as to enable the NC machine tool to complete the specified machining process. NC indexing is generally matched with NC milling machine and vertical machining center, which is used to process shaft and sleeve workpieces. The numerical control dividing head can be controlled by an independent control device, or by the numerical control device of the host through the corresponding interface.

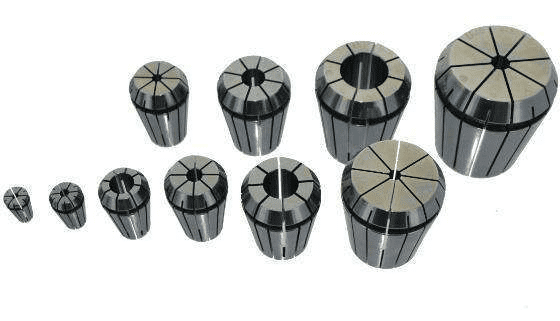

4. Milling tool handle

The spindle taper hole of machining center is usually divided into two categories: general system with taper of 7:24 And HSK vacuum system with taper of 1:10.

What are the most relevant factors for selecting chucks?

Several factors need to be considered when making a decision on which fixture is more effective. For a given lathe machining task, all of the following factors need to be considered to measure the choice of spring collet or jaw chuck.

1. Spindle load capacity

The maximum allowable weight of the lathe spindle is based on the bearing load capacity. If the weight of the chuck and workpiece combination is too large, the bearing may be overloaded. For those machining tasks with danger beyond the limit, this danger may determine people’s choice of workpiece fixture. The weight of jaw chuck is often larger than that of the same spring chuck. Therefore, the spring chuck is the appropriate choice when the weight needs to be controlled.

2. Spindle speed

Spring collet is often a better choice for turning at very high spindle speed for two main reasons:

One reason is related to the quality of the chuck. Assuming that the jaw chuck and spring collet are driven by the same spindle horsepower, the heavier jaw chuck takes longer to accelerate to the required speed. A long acceleration time will prolong the working cycle and reduce productivity.

Another reason is related to the centrifugal force, because it increases with the square value of RPM, so this value is very important in the case of high-speed cutting. For example, if you double the spindle speed, the centrifugal force will be four times the original. This force pulls the chuck jaws away from the center, often reducing the clamping force. However, with spring collet, centrifugal force will not cause obvious influence. Therefore, the clamping force will be more stable in the whole processing speed range.

3. Processing operation

The spring collet exerts clamping force on the whole circumference of the part, rather than only in the selected contact area. Therefore, good concentricity can be obtained, which is particularly important for secondary processing projects. The secondary processing needs to consider the accuracy related to primary processing, because the accurate clamping ability of the spring collet is strong, even when the jaw chuck is used for primary processing, The spring collet can also be used for secondary processing. The chuck with hollow soft jaws can achieve TIR (total reading) repetition accuracy in the range of 0.0006 to 0.0012 inches, while the typical repetition accuracy of the spring collet is 0.0005 inch TIR or better. In order to further improve the secondary machining accuracy, the concentricity of the spring collet can also be adjusted during installation.

4. Workpiece size

Spring collets are ideal for workpieces less than 3 inches in diameter. The spring collet limits the length of the workpiece. In particular, the spring collet limits the axial (Z-axis) travel range of the machine tool because its length is longer than the jaw chuck. When the machining length of the workpiece needs almost the whole available stroke of the machine tool, the jaw chuck is probably used.

5. Processing batch size

Spring collets are suitable for large and small batch processing tasks.

In the processing occasions of small batch and multiple tasks, the advantages of spring chuck are related to the product conversion time. The jaw exchange of standard jaw chuck takes about 15 to 20 minutes, the jaw chuck specially used for rapid replacement takes 1 minute, while the chuck exchange of quick replacement spring chuck only takes 15 to 20 seconds. When the product changes frequently, the saved time is considerable.

When the processing batch is large, the saved clamping related time can also be accumulated. The opening and closing time of the spring chuck is less than that of the jaw chuck. The processing cycle time can be reduced by reducing the non cutting time from one workpiece to the next workpiece.

6. Workpiece size range

The faster opening and closing of the spring collet is partly due to its short driving stroke. Compared with the jaw chuck, the spring collet is applicable to a more limited range of workpiece sizes.

In fact, the speed of the spring collet is elastic. If the workpiece size is consistent, the speed of the spring collet will be faster. If the workpiece size changes greatly, it may be necessary to use jaw chuck to adapt to the machining workpiece with a wide size range.

7. Material type

For hot rolled steel, forgings and molded parts, standard jaw chucks are often more effective because all such parts have inherent diameter changes. On the other hand, cold rolled material parts often have good dimensional consistency. Therefore, spring collets are suitable for selection. However, the lack of consistent diameter measurements does not necessarily constitute an obstacle to the use of spring collets. Collets designed for non-circular cross-section can be provided to hold molded bars made to the shape required by the customer.

8. Secondary spindle

Turning machines equipped with secondary spindles are often used for various mass machining. In these applications, spring collets can significantly save machining time. They can process all surfaces of parts in one working cycle. These machine tools are often combined with bar feeders to realize unattended production and continuous processing of workpieces. In these applications, for a workpiece, the saved chuck driving time may be very little, but in the whole production process, the saved time of each workpiece is multiplied by the number of processed workpieces, and the accumulated saved time is very considerable.

9. Chuck tool library

It is also important to consider the third option when people choose the most suitable workpiece clamping device between the jaw chuck and the spring collet. Where permitted, retaining two fixtures and changing from one to the other may be the most cost-effective option. Change from jaw chuck to spring collet, or vice versa, usually no more than 20 minutes. The jaw chuck can be retained on the machine to deal with the uncertainty of the part range. However, when the machine tool processes a large number of workpieces or several batches of parts with the same size, the productivity obtained by using the spring collet greatly exceeds the productivity loss caused by the time spent replacing the fixture.

How to solve the large runout of chuck products of NC lathe?

The fixture is six points (3 + 2 + 1: three-point fixed surface, two-point fixed line and one-point fixed), and machining needs to solve deformation and runout.

Is the tool handle too long? Is the tool holder rigid enough? Is the speed and feed appropriate? A series of problems will cause large runout of CNC lathe chuck products.

In high-speed cutting, due to large machining allowance and intermittent cutting, the milling process often produces vibration, which affects the machining accuracy and surface roughness.

Therefore, NC High-speed machining process can be generally divided into: rough machining – semi finishing – corner cleaning – finishing and so on. For parts with high precision requirements, it is sometimes necessary to carry out secondary and semi finishing, and then finish machining. After rough machining, the parts can be cooled naturally to eliminate the internal stress caused by rough machining and reduce deformation. The allowance left after rough machining shall be greater than the deformation, generally 1 ~ 2mm. During finish machining, the finished surface of parts shall maintain a uniform machining allowance, generally 0.2 ~ 0.5mm, so that the tool is in a stable state in the machining process, which can greatly reduce the cutting deformation, obtain good surface machining quality and ensure the accuracy of products.

The tool mainly produces radial runout during machining, which is mainly due to the aggravation of radial runout in radial cutting. Therefore, reducing radial cutting force is an important principle to reduce radial runout.