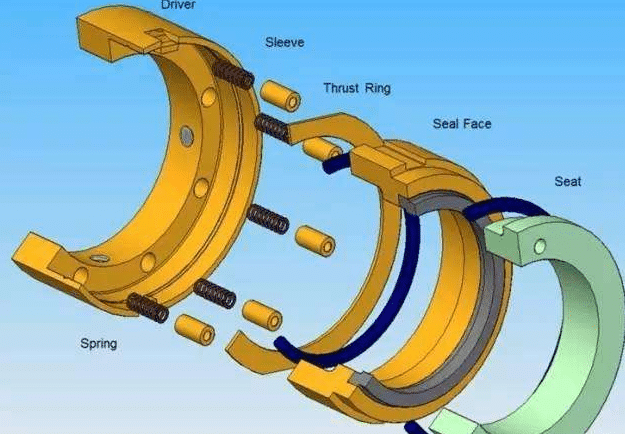

Mechanical seal is a device to prevent fluid leakage, which is composed of at least one pair of end faces perpendicular to the rotation axis under the action of fluid pressure, the elastic force (or magnetic force) of compensation mechanism and the cooperation of auxiliary seal to keep sticking and relatively sliding.

The mechanical seal structure is mainly composed of the following elements,

1. Stationary ring (stationary ring)

2. Rotating ring (moving ring)

3. Elastic element

4. Spring seat

5. Set screw

6. Rotary ring auxiliary seal ring

7. Stationary ring auxiliary seal ring

The anti rotation pin is fixed on the gland to prevent the stationary ring from rotating.

Mechanical seal has the advantages of reliable sealing performance, small leakage, long service life, less power loss and wide application range. It is widely used in various technical fields, especially in the working conditions of high speed, high pressure difference and expensive, toxic and highly corrosive process media. At the same time, mechanical seal is one of the weakest links of the equipment.

In order to prolong its service life, in addition to choosing the right friction pair material and the right end face specific pressure, the correct installation and maintenance can also play an important role.

In this paper, through the practice of daily maintenance, the main causes of mechanical seal failure and leakage are analyzed.

Cause analysis of mechanical seal failure and leakage

There are various types and models of mechanical seals used in chemical equipment, but there are five main leakage points:

① Seal between shaft sleeve and shaft;

② Seal between moving ring and shaft sleeve;

③ Sealing between dynamic and static rings;

④ Sealing between the stationary ring and the stationary ring seat;

⑤ Seal the seal between the end cover and the pump body.

Mechanical seal leakage caused by the wear of the end face of the dynamic and static ring

No matter which type of mechanical seal, the main feature is that the sealing face is perpendicular to the rotating axis, that is to say, the axial seal which is easy to leak is changed into the end seal which is not easy to leak. Therefore, the main form of mechanical seal failure is the wear failure between static and dynamic rings. The end friction pairs of the dynamic and static rings are mainly compressed by the spring thrust to prevent leakage. The tighter the dynamic and static rings are, the less likely they are to leak, but the friction between them also increases. The contact surfaces of the dynamic and static rings will wear quickly under the action of large friction, and finally fail to leak.

Mechanical seal leakage due to unstable process conditions and wrong installation

The vibration caused by unstable process conditions and poor installation, and the instantaneous disconnection of equipment evacuation and vaporization will lead to the damage of the liquid film between the dynamic and static rings of the mechanical seal, which will make the mechanical seal run “dry” under the condition of no lubrication. The temperature of the seal ring will rise rapidly, some of which will burn directly, some of which will be cooled sharply when the pump returns to normal working state, forming thermal shock and fragmentation. The poor flushing fluid and conditions will also cause thermal shock, which will lead to radial cracks in the seal ring and increase the wear failure of the dynamic and static rings. At the same time, when the temperature of graphite ring exceeds the service temperature, the crystal will precipitate on the surface of graphite ring, and carbonization will occur near the friction pair with higher temperature, and the particles will enter into the friction pair to make the dynamic and static ring wear out rapidly.

Failure of sealing ring of mechanical seal is also the main cause of seal leakage

The assembly of the sealing ring of the dynamic and static rings is askew; the surface finish of the shaft or sleeve matched with the sealing ring is not enough, or the matching size is too small; the physical or chemical reaction between the sealing ring and the sealing medium, corrosion, deformation, aging, etc. can lead to leakage.

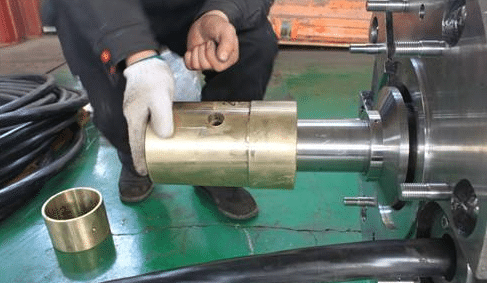

Mechanical seal leakage due to improper assembly

Before the assembly of mechanical seal, the cleaning of mechanical seal components is not clean, the components are bruised or scratched; the assembly is not in place; the spring assembly is biased, the fastening screws are not fastened; the mechanical seal is damaged during disassembly, etc., which are all the reasons for the early failure of mechanical seal.

Leakage of mechanical seal caused by improper selection and design of mechanical seal

Due to the diversity of process medium characteristics in chemical plant, improper selection of mechanical seal design, small and large pressure ratio of seal end face or large shrinkage of seal material, it is very easy to cause mechanical seal failure and leakage.

Solutions

According to the above analysis, the following measures and maintenance methods should be taken to prolong the service life of mechanical seal.

Spring compression adjustment

Adjusting the compression amount of spring is to adjust the specific pressure of the end face of mechanical seal, which is related to the important parameters of seal performance and service life, as well as the structural type of seal, spring size and medium pressure. If the specific pressure of the end face is too large, the friction pair will be damaged; if the specific pressure is too small, it is easy to leak, so the manufacturer usually gives a suitable range, generally 3-6kg / cm2. The free length of the spring a, the spring stiffness K (the load to bear when generating unit compression), and the specified specific pressure P are all parameters given by the manufacturer. When the compressed dimension is B, then p / (a-b) = k, and B = A-P / K, which is the compressed dimension of spring installation. If the size of the spring after installation is too large, the thickness of the adjusting pad can be increased between the spring seat and the spring. If the size is too small, the thickness of the adjusting pad can be reduced. The thickness of the adjusting pad shall be measured with a micrometer.

Tightness of moving ring seal ring

It is harmful and useless that the seal ring of the moving ring is too tight. First, it will aggravate the wear between the seal ring and the shaft sleeve and cause premature leakage; second, it will increase the resistance of the axial adjustment and movement of the moving ring, which can not be adjusted in time when the working condition changes frequently; third, the spring will be easily damaged due to excessive fatigue; fourth, it will deform the seal ring of the moving ring and affect the sealing effect. In order to ensure the floating property of the moving ring, its inner diameter is 0.5-1mm larger than the shaft diameter, which is used to compensate the vibration and deflection of the shaft, but the clearance should not be too large, otherwise the sealing ring of the moving ring will be clamped in and the mechanical performance of the mechanical seal will be damaged. The tightness of the sealing ring shall be subject to the pressure of one hand after applying lubricant.

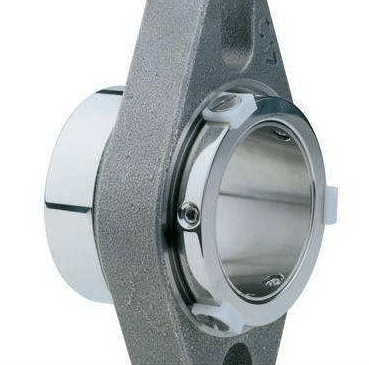

Tightness of static ring seal ring

The static ring seal is basically in a static state, and the sealing effect is better if it is relatively tight, but too tight will lead to: first, the static ring seal will be deformed excessively, which will affect the sealing effect; second, the static ring material is mostly graphite, which is generally brittle, and the excessive stress will easily lead to fragmentation; third, it is difficult to install and disassemble, which will easily damage the static ring. Therefore, the inner diameter of the static ring is generally 1-2mm larger than the shaft diameter, and the tightness of the sealing ring is subject to the pressure of both hands after the lubricant is applied. If the hand can be pressed in gently, it will be too loose; if the hand cannot be pressed in forcefully, it will be too tight.

Old and new seal replacement

Relatively speaking, the effect of using the new mechanical seal is better than the old one, but when the quality or material selection of the new mechanical seal is not right, the fitting size error will affect the sealing effect. In polymerizable and deep permeable media, if there is no excessive wear on the static ring (when the sealing surface is cracked, dropped, scratched, pockmarked, flash and eccentric wear, and the scratched and pockmarked points penetrate the entire sealing face, it is called excessive wear), it is better not to replace it. Because the static ring is in a static state for a long time in the static ring seat, the polymer and impurities are deposited as a whole, which plays a better sealing role.

Overhaul

Once the mechanical seal leaks, do not rush to dismantle and repair it. Sometimes the seal may not be damaged. Only adjust the working condition or adjust the seal properly can eliminate the leakage. For example, adjust the compression amount of spring, eliminate the vibration of running equipment, remove the scale that makes the spring lose its elasticity and the scale on the friction pairs of dynamic and static rings. In this way, it can not only avoid waste but also solve practical problems. At the same time, it can verify its fault judgment ability and accumulate maintenance experience to improve maintenance quality.